Join us at the International Thermal Conductivity Conference (ITCC) and the International Thermal Expansion Symposium (ITES).

Geological

Nanomaterials

Pastes

Pastes

Polymers

The Measurement Platform-2 (MP-2) is an advanced meter with unique selection of transient thermal conductivity sensors for a variety of applications, with a focus on primary measurements. The transient thermal conductivity sensors share similar principles of operation. The sensor wire is heated using a constant current source (q) and the temperature rise is recorded by monitoring the change in electrical resistance of the wire (THW and EFF) or by resistance temperature detector device (TLS). For samples of high thermal conductivity, the lower the slope; for samples of low thermal conductivity, the higher the slope.

Picture 1. Thermtest MP-2 Thermal Conductivity Meter

Thermal conductivity MP-2 users benefit from the convenience and accuracy gained when using primary testing methods. The MP-2 controller auto-detects the connected sensor and loads corresponding testing parameters. Measurements are easily performed with the smart on-board software and transferred to computer with an included Windows utility program.

Picture 2. Thermtest THW-L3 sensor for use with the MP-2 portable meter.

The THW-L3 sensor is one of the many sensors offered with the Thermtest Portable Measurement Platform (MP-2). This sensor offers simple yet accurate measurements of liquids, pastes, and powders from 0.01 to 1 W/m/K via the transient hot wire method. The THW-L3 adheres with an internationally recognized standard of testing by complying with ASTM D7896-19. The THW-L3 has a 5% accuracy and a 2% reproducibility of measurement, making it a highly accurate and precise instrument for measuring the thermal conductivity of liquids, pastes, and powders.

The THW-L3 has a detect current setting that determines the appropriate amount of current to apply based on a test measurement. By reading the result of the test measurement, a current will be set that results in an optimal temperature rise of the sample during testing. The accompanying sample holder can be filled with ~15ml of a powder sample and the sensor can be subsequently inserted in the sample holder. An alternative method of measuring the power is to insert the THW-L3 directly into the vessel containing the powder.

Powders are used and produced in a variety of industrial applications. Some examples would be mining/drilling, powder coating, and additive manufacturing (3D printing with powders). One way to characterize the powder being used or produced and ensure that the composition/purity of the powder is consistent is to measure the thermal properties of the powder.

In situations where varying temperatures are involved, it would be worthwhile to understand the thermal properties of the powder involved to prevent overheating and damage to the machinery that comes into contact with the powder. With the THW-L3, it is possible to measure the ability to conduct heat, or the thermal conductivity of the powder easily and accurately.

In this application sheet, two white powders are measured via THW-L3 and compared. The first powder is silica aerogel, a material known for its insulative properties. Aerogels have thermal conductivities of around 0.016 W/(m*K) [1]. The second powder is sodium sulfate, its primary application is in the production of detergents [2]. The thermal conductivity of sodium sulfate is not widely known. The following results are observed when measuring the two powders with the THW-L3 after using DIUF water as a calibration material.

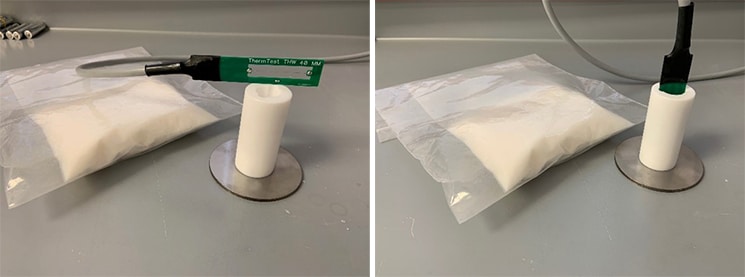

Figure 1: Measuring powders with the THW-L3. The powder is poured into the sample holder

and the sensor is then placed in the sample holder.

| Table 1: Results of measuring powders with the THW-L3. | ||

| Sample ID | Average Thermal Conductivity (W/m/K) | Standard Deviation (W/m/K) |

|---|---|---|

| Silica Aerogel | 0.017 | 0.0007 |

| Sodium Sulfate | 0.131 | 0.002 |

It can be observed that the thermal conductivity of the aerogel is an order of magnitude lower than that of sodium sulfate, meaning that the silica aerogel lives up to its reputation for being very insulative. The THW-L3 appears to have measured silica aerogel, a material that is near the lower limit of thermal conductivity for this sensor, with a high degree of accuracy.

1 Shanyu Zhao et al. Additive manufacturing of silica aerogels, Nature (2020). DOI: 10.1038/s41586-020-2594-0

2 Helmold Plessen. “Sodium Sulfates”. Ullmann’s Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH (2000). DOI:10.1002/14356007.a24_355