The HFM-25 is a portable heat flow meter for the measurement of thermal resistance and thermal conductivity of small samples of insulation and construction materials.

Best For small samples of insulation and construction materials.

The Heat Flow Meter (HFM-25) measures the thermal resistance and thermal conductivity of small samples of insulation and construction materials. Offering the testing power of a full-size heat flow meter, optimized for small insulation samples and budget.

The economic HFM-25 was designed to meet the growing need for steady-state testing of small samples of insulation for true thermal resistance and thermal conductivity.

Designed with simplicity in mind, a sample is positioned between the two heating – cooling plates. Plate contact is controlled manually, with variable pressure applied with the use of standard weights. Thickness is conveniently reported with included digital gauge. Testing on compressible samples is possible with included shims.

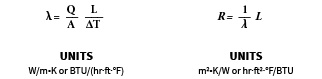

Ambient room temperature is automatically detected, users can choose from 5, 10, 15, and 20 °C delta ranges. One heat flux sensor is integrated into each plate and is used to monitor heat flux (Q/A), generated due to the difference in temperature (DeltaT) between the top and bottom plate at regular intervals until steady-state heat flux is observed. The composite heat flux is then used to measure thermal resistance (R) and calculate thermal conductivity (λ) according to Fourier’s Law.

Following international standards, the HFM Series is designed for testing both homogeneous and heterogeneous materials of a range of

sample dimensions.

| Models | HFM-100 | HFM-100 HT | HFM-50 | HFM-25 |

| Materials | Insulation, solids, and textiles | Insulation, solids, and textiles | Insulation, solids, and textiles | Insulation, solids, and textiles |

| Type of sensors | Flux sensors (x2) | Flux sensors (x2) | Flux sensors (x2) | Flux sensors (x2) |

| Thermal conductivity (W/m•K) | 0.002 to 0.5 | 0.002 to 0.5 | 0.002 to 0.5 | 0.01 to 0.3 |

| Specific heat | Optional | Optional | Optional | N/A |

| High thermal conductivity kit (W/m•K) | Optional (up to 2.5) | Optional (up to 2.5) | Optional (up to 2.5) | N/A |

| Sample size (mm) | 300 x 300 x up to 100 | 300 x 300 x up to 100 | 200 x 200 x up to 50 | Up to 300 x 300 x 25 |

| Test time (minutes) | 30 to 40 | 30 to 40 | 30 to 40 | 20 |

| Accuracy (Thermal conductivity)* | 1 to 2% | 1 to 2% | 1 to 2% | 3% |

| Repeatability (Thermal conductivity)* | 0.5 to 1% | 0.5 to 1% | 0.5 to 1% | 1% |

| Plate temperature range (°C) | -20 to 75** | -30 to 110** | -20 to 70** | 10 to 75 |

| Factory calibrated | Yes | Yes | Yes | Yes |

| Standard | ASTM C518, ASTM C1784, ISO 8301, JIS A1412, EN 12667, and EN 12664 | ASTM C518, ASTM C1784, ISO 8301, JIS A1412, EN 12667, and EN 12664 | ASTM C518, ASTM C1784, ISO 8301, JIS A1412, EN 12667, and EN 12664 | ASTM C518, ASTM C1784, ISO 8301, JIS A1412, and EN 12667 |

* Performance verified with NIST 1435d / 1450e

** Chilled circulator required

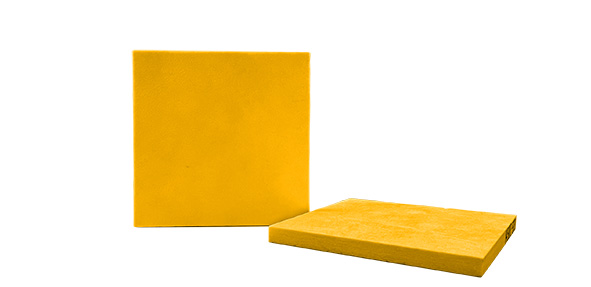

The homogeneity of NIST 1450d high-density fibrous glass board was measured with the HFM-25. Designed to test small samples or locations of 25 mm x 25 mm. The open concept sample clamping allows testing of large samples.

The four corners of the board were measured to analyze the homogeneity of sample. The % RSD from location to location was less then 1%, confirming the homogeneity.

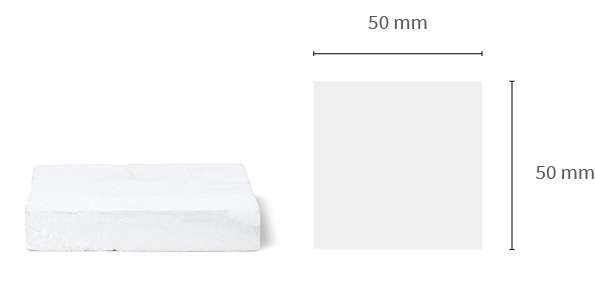

Aerogel blanket sample (50 x 50 x 9.58 mm) was selected to test by the HFM-25. Thermal conductivity of 0.014 W/m•K was measured at 23°C, which is within 3% of the manufacturer’s specification (measured by GHP – ASTM C177).

A sample of NIST SRM 1450d was measured for thermal conductivity for accuracy. The certified thermal conductivity for the NIST piece at 25°C is 0.0329 W/m•K. The measured thermal conductivity was 0.0330 W/m•K, which is within 1% of the certified value.

We are happy to arrange a live demonstration for you!