Diamond paste, an abrasive paste made from synthetic diamond powder and other raw materials, is renowned for its potent polishing capabilities. It’s frequently employed to polish and shine metals, hard alloys, glass, ceramics, gemstones, and even teeth in dental applications. While the mechanical properties and the influence of diamond particle concentration on these properties are well-understood, the impact of particle size on the thermal conductivity of diamond pastes is seldom addressed.

So, how does the diamond particle size influence the thermal conductivities of these polishing pastes? In this application, we will compare the thermal properties of six diamond pastes with varying grit sizes to determine the effect of diamond particle size on thermal conductivity.

Six samples of AMPLEX® water soluble diamond paste with variable grit sizes were measured for thermal conductivity (W/m·K), thermal diffusivity (mm²/s) and volumetric specific heat (MJ/m³K) using the Measurement Platform Versatile (MP-V) with the Transient Plane Source (TPS) Method: Standard Module with the TPS paste cell.

Polishing is a process that involves using an abrasive material to smooth and shine a surface. It works by eliminating scratches and nicks on the surface, thereby enhancing its luster. Not only are polished surfaces aesthetically pleasing, but they also tend to have longer lifetimes and function better compared to non-polished surfaces.

Diamond polishing pastes are formulated with synthetic diamond powder and surfactants. They can be either water or oil-based, which influences the grinding effect. Oil-based pastes are more suitable for metals and hard alloys, while water-based pastes are better suited for polishing gemstones, glass, and ceramics. Synthetic diamonds are used to ensure consistency in the shape of the diamond particles, guaranteeing even, sharp polishing. Despite being synthetic, they remain one of the hardest materials available, making them highly effective for polishing.

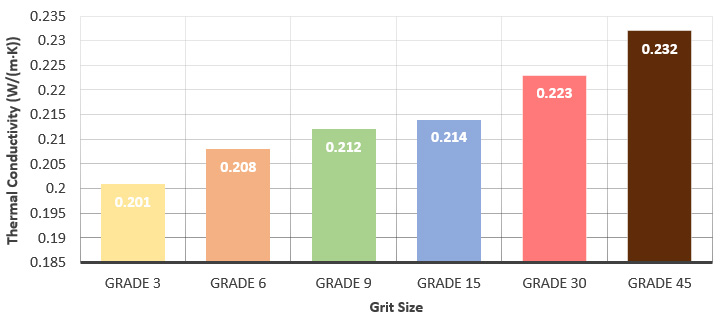

Diamond pastes come in different grades based on the size of the diamond particle, which are indicated by color. The lower the diamond grit, the smaller the particles, resulting in a smoother finish. Diamond, whether pure or synthetic, is known to have the highest thermal conductivity among all materials. It is expected that diamond pastes with higher grit have larger diamond particles, and therefore, higher thermal conductivities.

Figure 1. Diamond paste samples.

The MP-V is designed to test the absolute thermal conductivity, thermal diffusivity, specific heat, and thermal effusivity of solids, liquids, pastes, and powders. It features a powerful combination of the transient plane source (TPS, ISO 22007-2) and transient hot-wire (THW, ASTM D7896-19) methods, and is compatible with a variety of sensors. Transient methods share similar theories, with differences that are specific to their primary design. The sensors are electrically connected to a power supply and sensing circuit.

An electrical current passes through the sensor, leading to a temperature increase that is recorded over time. The heat generated is then diffused into the sample at a rate dependent on the thermal transport characteristics of the material.

Figure 2. Measurement Platform Versatile (MP-V)

The TPS paste cell is specifically designed to test pastes for thermal conductivity, thermal diffusivity and volumetric specific heat up to 300°C. The model features loading holes which are used to reduce the chances of air-pockets while adding the sample to the cell, as air pockets can introduce unwanted error.

Figure 3. TPS paste cell.

The diamond paste samples were measured in the symmetric configuration using the 3.2 mm radius double spiral TPS sensor (2117-1) and a TPS paste cell. Optimal measurement parameters of 40s and 50mW were determined for each sample.

Table 1. Thermal properties of diamond paste measured with MP-V at 23°C.

| Sample | Thermal Conductivity (W/m·K) | Thermal Diffusivity (mm²/s) | Volumetric Specific Heat (MJ/m³K) |

| Brown- Grade 45 (CZ13128) | 0.232 | 0.105 | 2.2 |

| Red- Grade 30 (CZ32350) | 0.223 | 0.096 | 2.3 |

| Blue- Grade 15 (CZ23108) | 0.214 | 0.086 | 2.5 |

| Green- Grade 9 (CZ23125) | 0.212 | 0.081 | 2.6 |

| Orange- Grade 6 (CZ13088) | 0.208 | 0.081 | 2.6 |

| Yellow- Grade 3 (CZ13125) | 0.201 | 0.088 | 2.3 |

n=5, 3.2mm (2117-1), 23°C, 40s, 50mW

Figure 4. Measured average thermal conductivities of diamond paste samples in W/(m·K)

Diamond paste is an effective polishing paste that can be utilized on a broad range of materials. There are different grades of this abrasive paste, determined by grit size and indicated by color. As predicted earlier in this application, the size of the diamond particles in the paste does influence the thermal conductivity of the sample. Pastes with higher grit sizes and larger diamond pieces were observed to have higher thermal conductivities than the lower grit diamond pastes.

References

Camacho, G. B., Vinha, D., Panzeri, H., Nonaka, T., & Gonçalves, M. (2006). Surface roughness of a dental ceramic after polishing with different vehicles and Diamond Pastes. Brazilian Dental Journal, 17(3), 191–194. https://doi.org/10.1590/s0103-64402006000300003

Diamond pastes. RS Components. (n.d.). https://uk.rs-online.com/web/c/hand-tools/sanding-filing-polishing/diamond-pastes/

Graebner, J. E. (1995). Thermal conductivity of diamond. Diamond: Electronic Properties and Applications, 285–318. https://doi.org/10.1007/978-1-4615-2257-7_7

Saint-Gobain Ceramics. (n.d.). Diamond Compounds. Surface Conditioning. https://www.surfaceconditioning.saint-gobain.com/products/diamond-compounds

What is diamond polishing paste made of?. B2ACCESSORIES. (2022, March 8). https://moldaccessories.com/en-ca/blogs/b2accessories/what-is-diamond-polishing-paste-made-of