Pyroceram® is a white, opaque and fine-grained glassy ceramic, known for its high mechanical strength, low coefficient of thermal expansion and large operational temperature range. It’s high temperature tolerance makes Pyroceram® an ideal material for applications where high heat is present, such as baking equipment. CorningWare® baking dishes became so popular because they are thermal shock proof and resistant to thermal expansion.

Pyroceram® also has very good low temperature tolerance and is commonly used in cryogenic systems, as bearings for example. This adaptability allows this glassy ceramic to be used in extreme heat and extremely cold or cryogenic conditions. There is extensive information published about Pyroceram®’s thermal properties in the presence of high temperatures but very little data on its thermal properties at cryogenic conditions.

So, how does Pyroceram® behave at extremely low temperatures? In this application, we will be exploring the thermal conductivity (W/m·K) of Pyroceram® at cryogenic temperatures.

Two identical samples of Pyroceram® were measured for thermal conductivity (W/m·K) using the MP-1 Transient Plane Source (TPS) Method: Standard Module. The MP-1 with TPS Standard Module measures the average or bulk thermal conductivity and thermal diffusivity of isotropic materials. This material was measured in the symmetric configuration using a cryogenic temperature platform with liquid nitrogen cooling.

Cryogenics is the branch of physics that deals with the production and effects of extremely low temperatures. The cryogenic temperature range is typically defined as -150°C to -273°C. At these extremely low temperatures that molecular motion comes as close to zero as possible. It is this point right before absolute zero in which all molecules are in their lowest possible energy states.

At these extreme conditions, properties such as thermal conductivity, ductility and electrical resistance are altered. Understanding how a material will function at extremely low temperatures is important for theorists and engineers to ensure the optimal material is being chosen for their product.

Ceramics are versatile materials used in a variety of applications, from flooring and baking equipment to heating and cooling devices in our homes. They are used as insulators on space shuttles, and even as gas turbine devices. Ceramic materials possess good mechanical properties, low thermal conductivity and low thermal expansion, making them suitable for cryogenic engineering.

High strength, elastic moduli and electrical resistivity also make this material a superior choice compared to some metals for certain cryogenic processes. Ceramics are widely used in space technology, military weaponry and other cryocooling conditions due to these advantages.

Figure 1. Pyroceram® sample.

Pyroceram® is an opaque glassy ceramic known for its high strength and large operational temperature range from -200°C to 1000°C. This innovative glass ceramic material was discovered in 1959 by Corning Glass® and was initially used for cooking and baking glassware. The company became CorningWare® in 1998 and still manufactures products made from Pyroceram®.

Pyroceram® has since become widely used in microwave ovens, hot plates and stirrers in laboratories, and even in air-force weapons due to its extreme stability and strength. While its thermal properties are well understood at high temperatures, very little has been researched about this ceramic glass at extremely low temperatures.

The MP-1 is designed to test the absolute thermal conductivity, thermal diffusivity and specific heat of solids, liquids, pastes and powders with the powerful combination of the transient plane source (TPS, ISO 22007-2) and transient hot-wire (THW, ASTM D7896-19) methods.

Figure 2. Measurement Platform-1 (MP-1) with Transient Plane Source Temperature Platform (TPS-TP).

When measuring the thermal properties of a material using the TPS Standard method, the TPS sensor is placed between two sample pieces for symmetric configuration or between the sample and known backing insulation for asymmetric configuration, each with plane surfaces facing the sensor. The solution to the thermal conductivity equation assumes the sensor is in an infinite medium, so the measurement and subsequent analysis of data must account for the available sample size and limitations created by the outer boundaries of the sample.

The samples of Pyroceram® were measured in the symmetric configuration using the standard 6.4mm radius double spiral TPS sensor (3317-1). The extreme low temperatures were achieved using a cryogenic temperature platform as well as liquid nitrogen cooling.

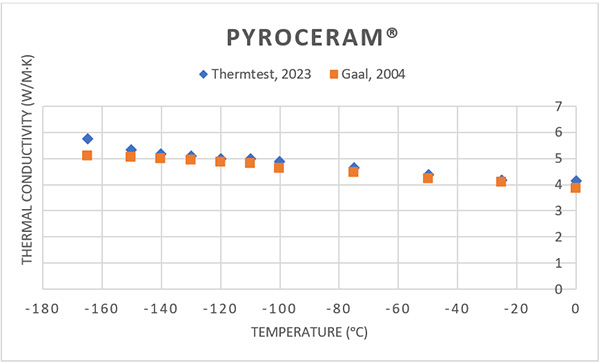

Table 1. Average measured and known thermal conductivities of Pyroceram® at cryogenic temperatures.

| Temperature (°C) | Thermal Conductivity (W/m·K) | Thermal Conductivity (W/m·K)(Gaal, 2004) |

| 0 | 4.122 | 3.829 |

| -25 | 4.197 | 4.082 |

| -50 | 4.394 | 4.213 |

| -75 | 4.659 | 4.483 |

| -100 | 4.887 | 4.631 |

| -110 | 4.986 | 4.778 |

| -120 | 4.972 | 4.835 |

| -130 | 5.073 | 4.933 |

| -140 | 5.170 | 4.991 |

| -150 | 5.340 | 5.039 |

| -165 | 5.731 | 5.089 |

Pyroceram, 6.4 mm radius (3317-1), 10 sec. 0.3 W, n=5

Figure 3. Thermal conductivity of Pyroceram® with temperature.

Pyroceram® has unique characteristics of high hardness, low thermal expansion, and wide range of working temperatures that make this material an ideal choice for anything from everyday household items to aerospace technologies. In this application, we measured Pyroceram® at extreme low temperatures with the MP-1 TPS with liquid nitrogen cooling.

Gaal, P. S., Thermitus, M.-A., & Stroe, D. E. (2004). Thermal conductivity measurements using the flash method. Journal of Thermal Analysis and Calorimetry, 78(1), 185–189. https://doi.org/10.1023/b:jtan.0000042166.64587.33

Kalia, S. (2009). Cryogenic processing: A study of materials at low temperatures. Journal of Low Temperature Physics, 158(5–6), 934–945. https://doi.org/10.1007/s10909-009-0058-x

Radebaugh, R., & Bar-Cohen, Y. (2017). Chapter 14: low temperature materials and mechanisms- Applications and challenges. Low Temperature Materials and Mechanisms, 437–476. https://doi.org/10.1201/9781315371962-15

Salmon, D. R., & Tye, R. P. (2010). Pyroceram® 9606, a certified ceramic reference material for high-temperature thermal transport properties: Part 1—material selection and characterization. International Journal of Thermophysics, 31(2), 338–354. https://doi.org/10.1007/s10765-010-0709-9

Xia, Z., Wu, Y., Ma, T., Bao, Z., Tian, J., Gao, L., Sun, J., & Li, S. (2022). Experimental study on adaptability of full ceramic ball bearings under extreme conditions of cryogenics and heavy loads. Tribology International, 175, 107849. https://doi.org/10.1016/j.triboint.2022.107849