Best For Liquids, Solids, Pastes and Powders

Standard Test

Method

Primary Measurement

Sensors

The MP-2 is an economical meter with a unique selection of transient thermal conductivity sensors for a variety of applications, with a focus on primary measurements.

The MP-2 is an economical meter with a unique selection of transient thermal conductivity sensors for a variety of applications, with a focus on primary measurements.

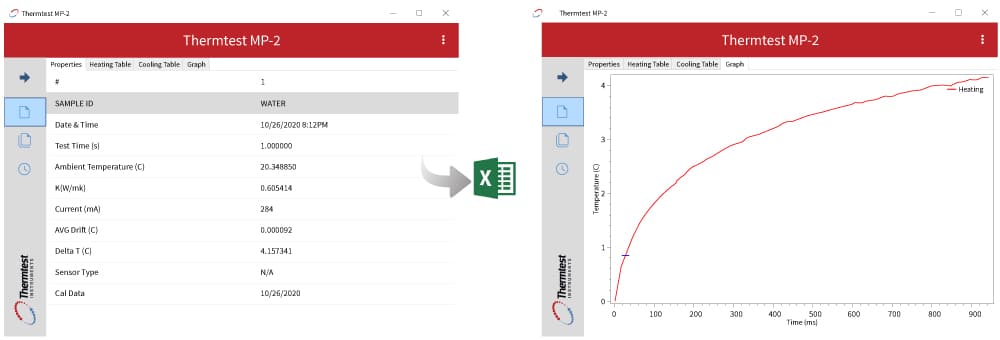

The controller auto-detects the connected sensor and loads corresponding testing parameters. Measurements are easily performed with the smart on-board software and can be transferred to a computer with the included data utility program.

For convenience, the auto-testing function can be setup directly on the controller or on a computer. Additional features include the ability to review, save or delete and export results to Excel. To maximize portability, power can be supplied by battery or USB cable. Informative screen icons showcase power status and testing progress.

| SENSORS | MATERIALS |

|---|---|

| MTPS | Solids, pastes and powders |

| THW | Liquids |

| TLS 50 mm | Concrete, rock and polymers |

| TLS 100 mm | Soils and polymers |

| TLS 150 mm | Soils and polymers |

| TPS-EFF | Fabrics and solids |

| Materials | Solids, pastes and powders |

| Thermal conductivity (W/m·K) | 0.029 to 20 |

| Thermal effusivity (W√s/m²K) | N/A |

| Thermal resistivity (mK/W) | N/A |

| Sample size (mm) | 25 diameter or square |

| Largest sample size | Unlimited |

| Test time (seconds) | 10, 20 and 40 |

| Accuracy (Thermal conductivity) | 5% |

| Repeatability (Thermal conductivity) | 2% |

| Temperature range (°C) | 0 to 80 |

| Moisture range | N/A |

| Standards | N/A |

Transient Hot Wire (THW-L3): For testing the thermal conductivity of liquids following ASTM D7896-19.

THW-L3

THW-L3| Materials | Liquids |

| Thermal conductivity (W/m·K) | 0.01 to 1 |

| Thermal effusivity (W√s/m²K) | N/A |

| Thermal resistivity (mK/W) | N/A |

| Sample size (mL) | 15 mL |

| Largest sample size | Unlimited |

| Test time (seconds) | 1 |

| Accuracy (Thermal conductivity) | 5% |

| Repeatability (Thermal conductivity) | 2% |

| Temperature range (°C) | 0 to 80 |

| Moisture range | N/A |

| Standard | ASTM D7896-19 |

TLS 50mm

|

TLS 100mm

|

TLS 150mm

|

|

| Materials | Concrete, rock and polymers | Soils and polymers | Soils and polymers |

| Thermal conductivity (W/m·K) | 0.3 to 5 | 0.1 to 5 | 0.1 to 3 |

| Thermal resistivity (mK/W) | 0.2 to 3.3 | 0.2 to 10 | 0.3 to 10 |

| Sample size (mm) | 50 length, 50 diameter | 100 length, 50 diameter | 150 length, 50 diameter |

| Largest sample size | Unlimited | Unlimited | Unlimited |

| Test time (seconds) | 180 | 180 | 180 |

| Accuracy (Thermal conductivity) | 5% | 5% | 5% |

| Repeatability (Thermal conductivity) | 2% | 2% | 2% |

| Temperature range (°C) | -40 to 100°C | -40 to 100°C | -40 to 100°C |

| Moisture range | N/A | N/A | N/A |

| Standards | N/A | ASTM D5334-22a, IEEE 442-1981 | ASTM D5334-22a, IEEE 442-2017 |

Transient Plane Source (TPS-EFF): For testing warmth or coolness of fabrics and textiles. Conforms to industry standards following ASTM D7894.

| Materials | Fabrics and solids |

| Thermal conductivity (W/m·K) | N/A |

| Thermal effusivity (W√s/m²K) | 35 to 1700 |

| Thermal resistivity (mK/W) | N/A |

| Sample size (mm) | 30 diameter |

| Largest sample size | Unlimited |

| Test time (seconds) | 2 and 10 |

| Accuracy (Thermal conductivity) | 5% |

| Repeatability (Thermal conductivity) | 2% |

| Temperature range (°C) | -10 to 50 |

| Moisture range | 0 to 90% (non-condensing) |

| Standards | ASTM D7984 |

We are happy to arrange a live demonstration for you!