The Measurement Platform-2 (MP-2) is an advanced meter with unique selection of transient thermal conductivity sensors for a variety of applications, with a focus on primary measurements. The transient thermal conductivity sensors share similar principles of operation. The sensor wire is heated using a constant current source (q) and the temperature rise is recorded by monitoring the change in electrical resistance of the wire (THW and EFF) or by resistance temperature detector device (TLS). For samples of high thermal conductivity, resistance increases more slowly over time; for samples of low thermal conductivity, resistance increases more quickly over time.

Picture 1. Thermtest MP-2 Thermal Conductivity Meter

Thermal conductivity MP-2 users benefit from the convenience and accuracy gained when using primary testing methods. The MP-2 controller auto-detects the connected sensor and loads corresponding testing parameters. Measurements are easily performed with the smart on-board software and transferred to computer with an included Windows utility program.

Picture 2. Thermtest THW-L3 sensor for use with the MP-2 portable meter.

The THW-L3 sensor is one of the many sensors offered with the Thermtest Portable Measurement Platform (MP-2). This sensor offers simple yet accurate measurements of liquids, pastes, and powders from 0.01 to 1 W/m·K via the transient hot wire method, and has a temperature range of 10°C to 40°C. The THW-L3 adheres with an internationally recognized standard of testing by complying with ASTM D7896-19. The THW-L3 has a 5% accuracy and a 2% reproducibility of measurement, making it a highly accurate and precise instrument for measuring the thermal conductivity of liquids, pastes, and powders.

The THW-L3 has a detect current setting that determines the appropriate amount of current to apply based on a test measurement. By reading the result of the test measurement, a current will be set that results in an optimal temperature rise of the sample during testing. The accompanying sample holder can be filled with ~15ml of any liquid sample, and the sensor can be subsequently inserted in the sample holder. An alternative method of measuring the thermal conductivity of a liquid sample is to insert the THW-L3 directly into the vessel containing the sample.

Aqueous sugar solutions, or sugar waters, are a main ingredient in many soft drinks, juices, and other food products. The thermal conductivity of sugar water varies depending on the concentration, and is important to know in terms of processing, transportation, and storage. Pasteurization is a mild heat treatment process that many foods and beverages undergo to prolong their shelf lives. The thermal conductivity of the food product is important during this process in order to predict and control how the food will be affected. This application sheet will use the Thermtest THW-L3 sensor to measure the thermal conductivity of sugar water at varying concentrations.

For this experiment, five samples of different concentrations of aqueous sugar solutions were measured. The first sample was pure DIUF water, or 0% sugar water. The fifth sample was 100% concentrated sugar water. The second, third, and fourth samples were 25%, 50%, and 75% sugar water, respectively. Each mixture was poured into the THW-L3 sample cell, then the sensor was inserted into the cell. The thermal conductivity of each sample can then be measured with a high degree of accuracy.

Figure 1: Samples of aqueous sugar solutions in varying concentrations. From left to right, 0% (pure DIUF water); 25% ; 50% ; 75% ; 100% saturated sugar.

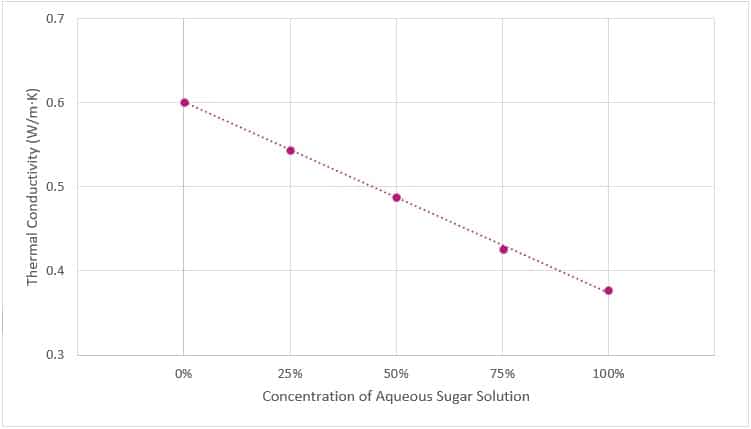

Figure 2: Results of measuring varying concentrations of aqueous sugar solutions at room temperature with the THW-L3.

Table 1: Results of measuring varying concentrations of aqueous sugar solutions at room temperature with the THW-L3.

| Concentration of Sugar | Average Thermal Conductivity (W/m·K) | Relative Standard Deviation (%) |

|---|---|---|

| 0% | 0.601 | 1.87 |

| 25% | 0.544 | 1.19 |

| 50% | 0.488 | 1.60 |

| 75% | 0.426 | 1.31 |

| 100% | 0.377 | 1.20 |