Picture 1. Thermtest MP-2 Thermal Conductivity Meter

Thermal conductivity MP-2 users benefit from the convenience and accuracy gained when using primary testing methods. The MP-2 controller auto-detects the connected sensor and loads corresponding testing parameters. Measurements are easily performed with the smart on-board software and transferred to computer with an included Windows utility program.

Picture 2. Thermtest TPS-EFF sensor for use with the MP-2 portable meter.

The TPS-EFF is a portable thermal effusivity meter for textiles, fabrics, and solids, and adheres with an internationally recognized standard of testing by complying with ASTM D7984-16. This sensor has a thermal effusivity measurement range of 35 to 1700 (W√s/m2K) and a temperature range of -10 ºC to 50 ºC. A single measurement can be set to 2 or 10 seconds in duration. The TPS-EFF has a 5% accuracy and a 2% reproducibility of measurement, making it a highly accurate and precise instrument for measuring the thermal effusivity of textiles, fabrics, and solids.

In non-solid samples, there are more modes of heat transfer than solely conduction. When other heat transfer mechanisms such as convection and radiation are present in the sample, thermal conductance becomes a more appropriate term than thermal conductivity. Therefore, thermal effusance is more appropriate to use over thermal effusivity in the case of these measurements.

Thermal effusivity is most typically measured to predict how ‘cool’ or ‘warm’ a material feels. It has a square root proportionality to the density, thermal conductivity, and specific heat capacity of the material. Highly dense samples made of materials with high thermal conductivity and specific heat capacity values have high thermal effusivity values, and vice versa. Depending on the situation, one might want a material to feel hot or cold to instill a feeling of comfort to the user. For example, a user would want a winter coat to feel warm in cold weather or a car interior to feel cool in the summer.

In terms of vehicle interiors, there are a few different choices for seat materials. Leather is often found in more expensive cars as it is more attractive than simpler cloth seats, however it is also more susceptible to changes in temperature. Sitting on leather seats in a car that has been in the sun during the summer can be very uncomfortable, as well as getting into a car during the winter. The use of a cloth seat cover during certain months may be helpful in ensuring the vehicle seats are as comfortable as possible.

The apparent thermal effusivity/thermal effusance (W√s/m2K) of leather and cloth were measured at four different temperature points (-10°C, 5°C, 20°C, and 35°C) using TPS-EFF (Transient Plane Source-Effusivity) to determine the effect of temperature on thermal effusance. Lexan was used as a control material that was not expected to change much in thermal effusance over the different temperature points, as it is smooth and homogenous. Test times of 2 and 10 seconds were used to simulate both short and long touch times to determine how the materials feel upon first contact, and how they feel once the heatwave from the TPS-EFF has penetrated the sample. It is expected that the leather will have a greater range of effusance values over the temperature points than the cloth seat cover would. A customer may therefore choose to have cloth seat covers over their leather seats during certain seasons, to avoid an extremely hot or cold car seat which would be uncomfortable.

Figure 1: Temperature-controlled chamber

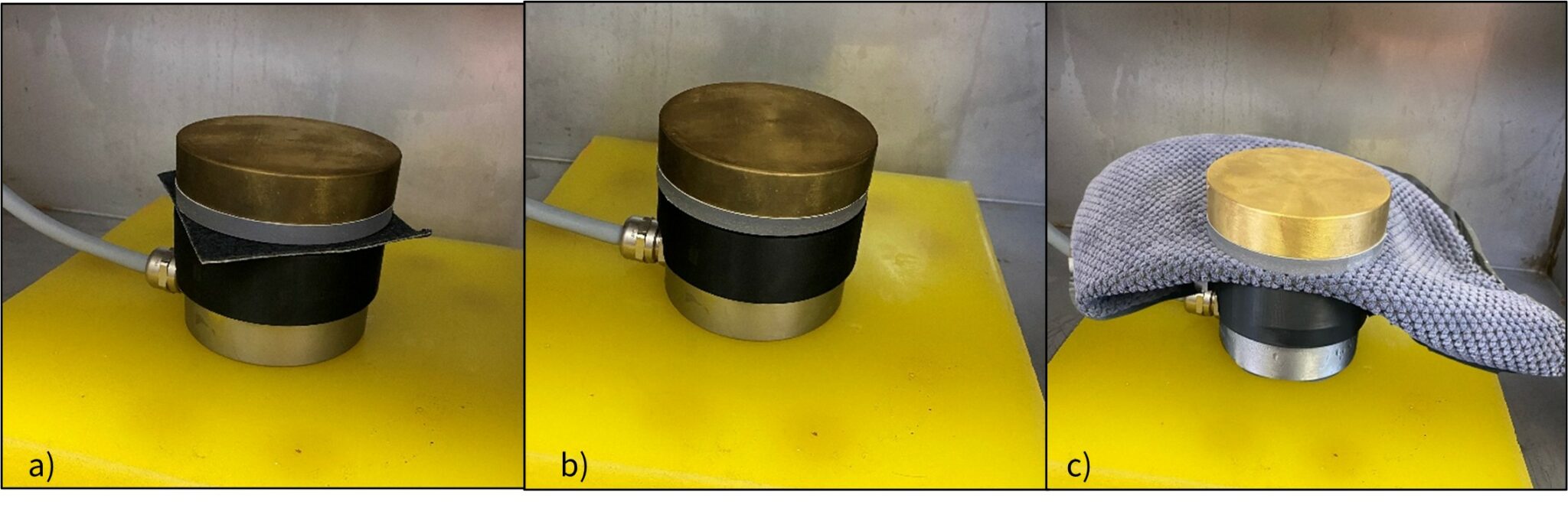

Figure 2: experimental set up of a) leather, b) lexan (control material), and c) cloth from a seat cover. The TPS-EFF sensor was placed face up with the sample on top of it, and a ~600g brass weight was put on top to ensure proper contact between sensor and sample.

Table 1: Results of measuring lexan, leather, and cloth with the TPS-EFF over a range of temperatures

| Temperature (°C) | ||||

|---|---|---|---|---|

| -10 | 5 | 20 | 35 | |

| Sample | Apparent Thermal Effusivity (W√s/m2ꞏK) | |||

| Lexan | 548.7 | 576.8 | 590.1 | 613.0 |

| Leather | 266.5 | 295.8 | 321.1 | 344.1 |

| Cloth | 51.6 | 80.4 | 82.0 | 87.6 |

As shown in Table 1, the apparent thermal effusivity increases with temperature for each of the samples that were tested. Leather has the greatest range of effusivity values, and cloth has the smallest range. This means that the leather seats would feel colder in cool weather, and hotter in warm weather than the cloth seat cover would. For car seats that are subject to extreme temperatures, a material with lower effusivity would be more comfortable, as it would cause less temperature shock from the difference in temperature between the material and the user.

The TPS-EFF has a 5% accuracy and a 2% reproducibility of measurement, making it a highly accurate and precise instrument for measuring the thermal effusivity of textiles, fabrics, and solids.