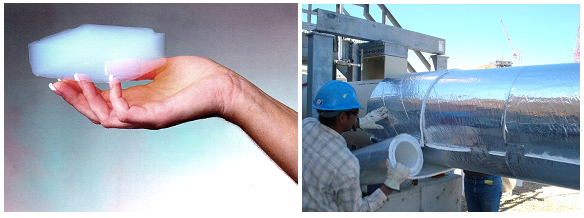

Aerogel blankets are an important new design in the world of research. The low thermal conductivity of aerogel (Figure 1) is lowest thermal conductivity known to solids.

Aerogels are a lightweight, low-density material derived from silica gels, in which there is an absence of liquid, ultimately replaced by gas.

This low thermal conductivity, and therefore high insulative capability can be attributed to both the presence of small, nano-sized pores filled with air, comprising 97% of the material, as well as small, scattered clusters of silica solids, encompassing the remaining 3%. Aerogels themselves are extremely fragile, however the blanket-gel combination is a flexible, high-tech insulation which may be used for many applications, for example, in aerospace, appliances, apparel and pipelining (Figure 1).These newly engineered blankets combine the innovative thermal capabilities of aerogels, with the extreme flexibility of textiles, to provide a versatile product with the prestigious title of world’s lowest thermal conductivity among solids.

Figure 1. Aerogels 1 (left) are a light and breakable material, experiencing a low thermal conductivity. However, when combined with textiles, they create a flexible and durable, high-tech insulation, for many applications, such as pipelining 2 (right). The thermal conductivity of aerogel is its greatest feature.

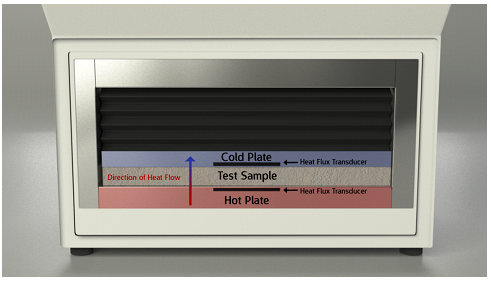

The Thermtest Heat Flow Meter Method (HFM) is designed to measure the thermal properties of flat slab insulating materials, such as solids, foams, and textiles (Figure 2). This instrument is capable of measuring thermal conductivities from 0.005 to 0.5 W/m·K, over a temperature range of -20°C to 70°C, in accordance with ASTM C518-15 – Standard Test Method for Steady-State Thermal Transfer Properties by Means of the Heat Flow Meter Apparatus.

For this experiment, researchers at Thermtest measured the thermal conductivity of aerogel blanket, using the Thermtest Heat Flow Meter (HFM). The objective of this experiment was to confirm the reported accuracy and precision of the Thermtest HFM, while discovering the tremendous thermal capabilities of aerogel blankets. The reported precision of the Thermtest HFM is 0.5%, or better, and the reported accuracy of measurement is 3%, or better.

Figure 2. The Thermtest Heat Flow Meter (left), is a steady-state heat transfer technique capable of measuring the thermal conductivity of solids, foams, and textiles, such as aerogel thermal conductivity blankets 3 (right).

To begin testing the thermal conductivity of aerogel, the blanket was placed inside of the HFM housing. The parallel plates were then set to automatically adjust to the height of the specimen. The auto adjustment method functions when four digital encoders, one in each corner of the upper plate, perform sample thickness measurements at their respective locations. An average of those thicknesses was then calculated and the upper plate compressed onto the specimen to the calculated thickness. The parallel plates, on either side of the sample, then established a steady state one-dimensional heat flux through the aerogel blanket, at constant but distinct temperatures (ex: 10 ºC and 30 ºC) (Figure 2). This temperature plate difference was set to mimic heat loss from a warm internal environment, to a colder external environment, and vice-versa.

Figure 3. View from inside the HFM door. Parallel plates (red and blue) establish a one-dimensional heat flux through the test specimen, at a desired median temperature (ex: 20˚).

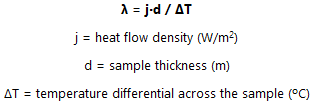

Prior to testing the aerogel thermal conductivity, a preliminary test was performed on a selected standard to calibrate the heat flux transducer(s). To calculate thermal conductivity (λ), the values from the calibration of the heat flux transducers, the plate temperature recordings and the plate separation measurement, were inputted into Fourier’s law of heat conduction:

The aerogel blanket displayed a thermal conductivity reading of 0.024 W/mK at 20˚C. Because aerogel thermal conductivity is so low, it is possible to insulate a sensitive environment from a harsh one, such as cryogenic or heat intensive environments. Presently, the main use of aerogel blankets is for insulation applications in industrial and commercial construction of buildings. Aerogels not only improve the energy efficiency of buildings, but due to their thin and sleek nature, they can drastically reduce the thickness of building envelopes.

According to the manufacturer, the known thermal conductivity of this aerogel blanket is 0.023 W/mK at 100˚C. As can be seen, by these results, a close correlation exists between the stated manufactured thermal conductivity and the value received from testing. A slight variation in data can be attributed to variations in testing temperature, as well as the moisture levels of the aerogel blanket upon testing. The Thermtest HFM is a simple, rapid, method for determining the thermal conductivity (W/m·K) of flat slab insulating materials, such as aerogel blankets, from a single, steady-state measurement. Users can expect a high degree of accuracy (3%) and precision (0.5%) with this ASTM traceable measurement technique.

The Thermtest Heat Flow Meter (HFM) provides users with the ability to measure thermal properties of larger, flat slab specimens ranging in thermal conductivities from 0.005 to 0.5 W/m∙K. The Heat Flow Meter is capable of measuring the steady-state heat transfer properties of foams, solids, and textiles.

ASTM C518-15, Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus, ASTM International, West Conshohocken, PA, 2015.

www.astm.org

http://www.innovationintextiles.com/aerotherm-aerogel-insulation-brings-space-technology-to-everyday-life/

http://www.aerogel.com/

http://www.aerogel.com/_resources/common/userfiles/file/Data%20Sheets/Pyrogel_XT_DS.pdf

Image References: