A thin-film is a layer of material ranging from fractions of a nanometer to several micrometers in thickness and can be anything from protective or optical coatings to electrical insulation. The ability to accurately determine the thermal conductivity for Kapton thin-films is critical for the performance and thermal management of many electrical devices. However, measuring the thermal conductivity of materials at such a nanoscale can be a challenge. The thermal conductivity of thin-films is influenced with thickness. Therefore, being able to accurately measure the thickness is an essential step in measuring the thermal conductivity. So, how is it possible to accurately measure the thickness and thermal conductivity of thin-films?

This application will focus on describing how to simply and accurately record the thickness of thin-films and subsequently measure their thermal conductivity (W/m·K) and thermal resistance (mm2/s).

Sheets of 100MT Kapton® polyimide film were measured for thermal resistance (m2K/W) and thermal conductivity (W/m·K) using the MP-1 Transient Plane Source (TPS) method: Proprietary Transient Thermal Resistance (TTR) Module.

Kapton® polyimide film is a thin flexible material often used in small electronics. Since its development by Dupont™ in the 1960s, this high-performing film has been essential for many applications because of its ability to maintain its electrical, thermal, chemical, and mechanical properties at extreme temperatures from as low as -269ᵒC up to 400ᵒC while also being pliable and lightweight.

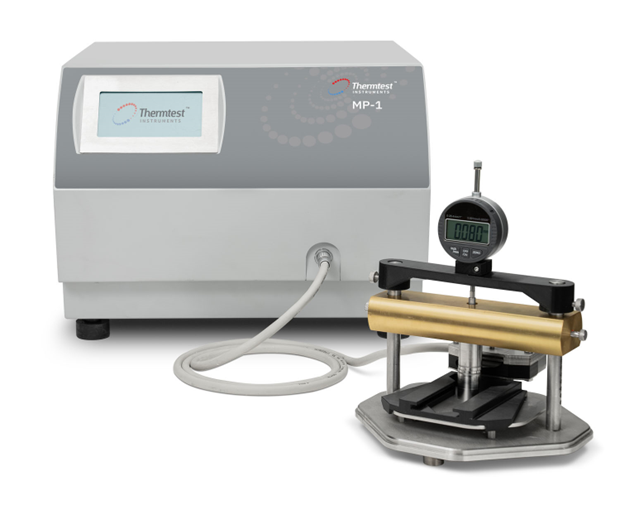

The MP-1 is designed to test the absolute thermal conductivity, thermal diffusivity and specific heat of solids, liquids, pastes and powders with the powerful combination of the transient plane source (TPS, ISO 22007-2) and transient hot-wire (THW, ASTM D7896-19) methods. For samples between 0.01 to 1mm thick and conductivity between 0.05 to 5 W/m·K, the MP-1 TPS with transient thermal resistance (TTR) modifier is used. This modifier allows for the measurement of thermal resistance and thermal conductivity of films, adhesives, pastes, and coatings.

Figure 1. MP-1 Transient Thermal Resistance (TTR) module.

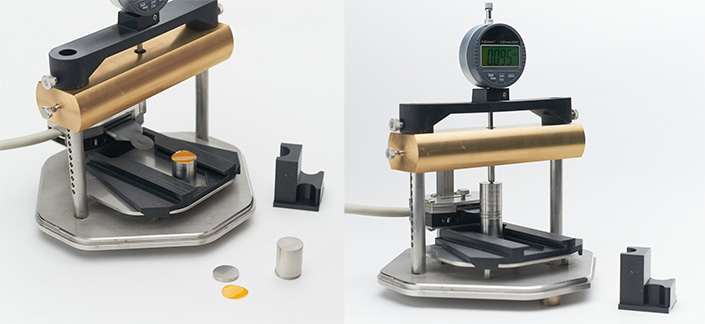

To measure the thermal conductivity of thin-films, pastes and coatings using the transient thermal resistance module, four pieces of stainless steel are used as substrates to deposit the thin-film samples onto. The sample set up includes (from top to bottom): 25mm substrate, thin-film sample, 3mm substrate, TPS sensor (4617-1), 3mm substrate, thin film sample, 25mm substrate.

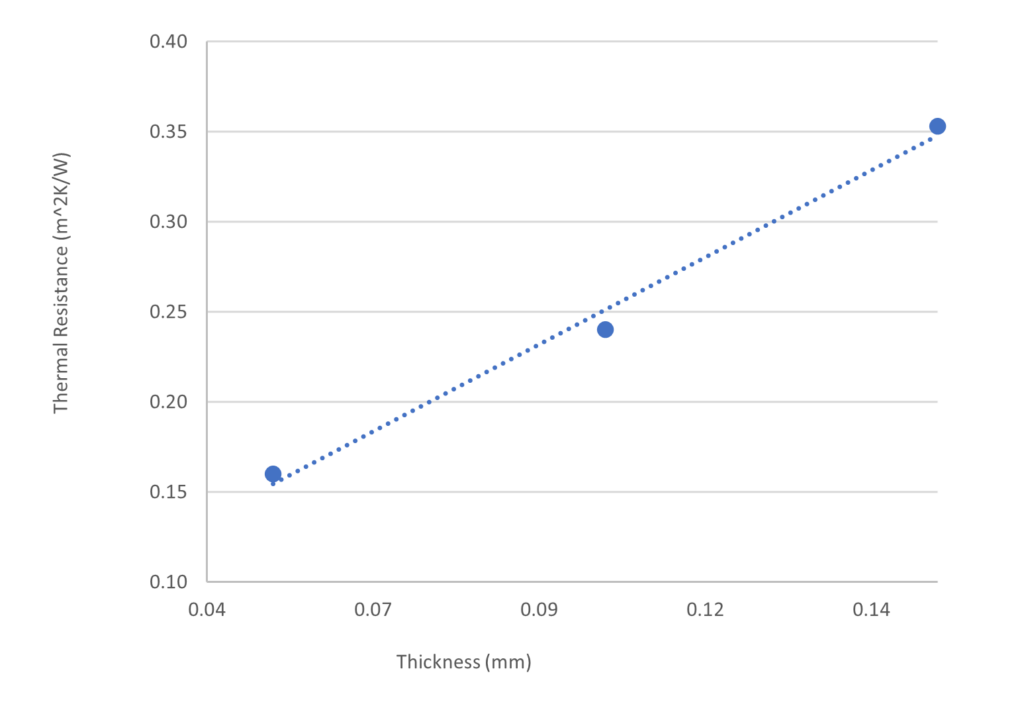

Similar to the testing of thin-films in ASTM D5470 and E1530, stacking layers may be used to reduce error from contact resistance when testing free-standing films. Due to the lack of contact resistance when testing pastes and adhesives, stacking is typically not required. The thermal resistance of the thin-films is plotted against the known thickness of the material and the inverse of the slope of this linear fit is the resulting thermal conductivity of the material.

The MP-1 transient thermal resistance height meter is first zeroed on the stainless-steel substrates without the thin-film samples. Once the height gauge has been zeroed, the thin-film samples are added or deposited to the substrates (fig. 2), and the thickness of the samples is displayed on the height meter.

Figure 2. Measuring the thickness of thin film samples with the MP-1 transient thermal resistance module.

There are countless different fields that rely on thin-films and benefit from their diverse abilities. This is why they are used in many different industries and applications. Insulative thin-films and tapes such as Kapton® have been used in a variety of markets including electronic devices (as and electronic insulator), batteries, power transformers, and more. Thanks to their semiconductor properties, thin-films share traits of both insulators and semiconductors. As a semiconductor, a thin-film regulates the electron mobility in a device to maintain balance when conducting electricity.

Not only are thin-films used in electronic devices, but they are also used for protective, optical or aesthetic purposes such as coatings for lenses and mirrors. In all these applications it is essential to measure and regulate their thickness accurately, as it influences their performance.

Three layers of 100MT Kapton® polyimide film were measured for thermal resistance (mm2/s) and thermal conductivity (W/m·K) with a drop of ethylene glycol between each layer to act as a contact agent. The inverse of the slope of the line gave a thermal conductivity of 0.517 W/m·K. When comparing the measured and supplier value (0.46 W/m·K by ASTM D5470) thermal conductivity for 100MT Kapton®, the value measured using the MP-1 with TPS TTR-TF was within 5.6%.

Table 1. Thickness and resistance measurements of 100MT Kapton® thin film samples.

| Number of Layers | Film Thickness (µm) | Thermal Resistance 10-3 (m2K/W) |

| One Layer | 50 | 0.159 |

| Two Layers | 100 | 0.240 |

| Three Layers | 150 | 0.353 |

100MT Kapton®, 9.9 mm radius (4617-1), 5 sec. 1 W, 23°C, n=5.

Figure 3. Thermal resistance of 100MT Kapton® thin-film samples at different thicknesses (increasing layers).

Table 2. Thermal conductivity results of 100MT Kapton polyimide film samples.

| Results | 100MT Kapton© |

| 1/Slope | 1/1.93 |

| Thermal Conductivity (W/m·K) | 0.517 |

Measuring the thermal conductivity of thin-film samples can be difficult and tedious. Thermal properties as well as mechanical, electrical, and optical qualities of thin-film samples are influenced with different sample thicknesses, so obtaining accurate thickness measurement is crucial. With the MP-1 TPS TTR-thin-film module, recording the thickness, and taking thermal measurements is combined into one process to give accurate thermal property results.

Reference:

Kapton® MT and Kapton® FMT Thermally Conductive Films. (n.d.). Www.dupont.com. Retrieved June 5, 2023, from https://www.dupont.com/products/kapton-mt.html