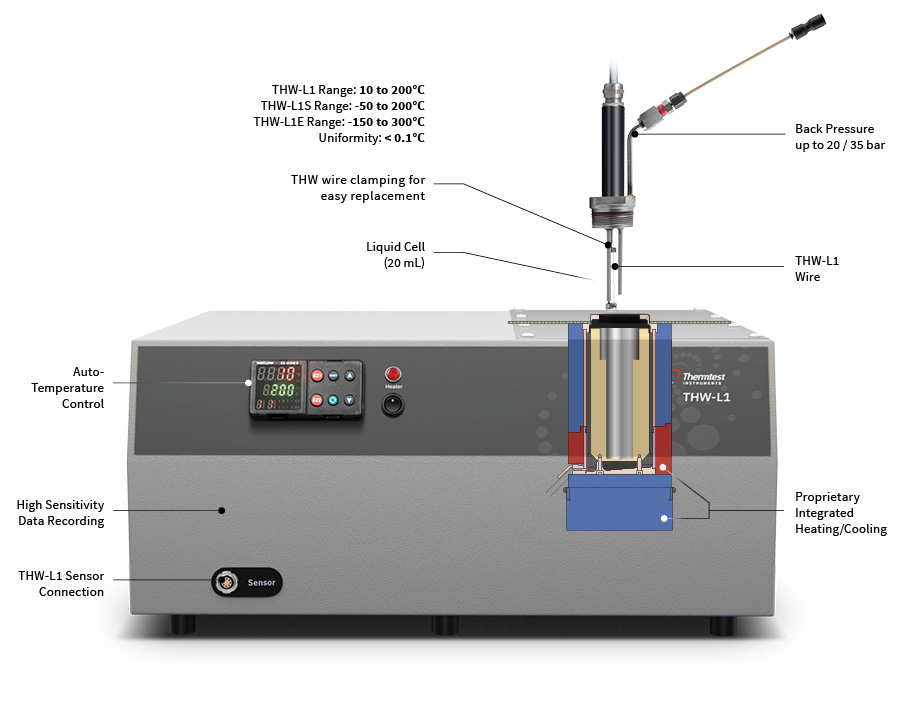

The Transient Hot Wire (THW-L1) is a laboratory instrument for thermal conductivity, thermal diffusivity and specific heat of liquids and PCMs.

Best For Liquids and PCMs

The THW-L1 following ASTM D7896-19, is widely used for the accurate measurement of thermal conductivity, thermal diffusivity, and specific heat of liquids and PCMs. This versatility is greatly expanded with the addition of Thermtest’s proprietary Temperature Platform (TP) which is appreciated by academic and commercial users alike.

The Transient Hot-Wire (THW) has been used for the testing of liquids for more than 30 years, making it one of the most published methods for measuring thermal conductivity of liquids available.

Please enter your email to download this brochure.

The Transient Hot-Wire (THW-L1) Liquid Thermal Conductivity Meter is an advanced measurement system for primary measurements of thermal conductivity, thermal diffusivity, and specific heat instrument for measurement of liquids and PCMs in accordance with ASTM D7896-19. The THW-L1 was designed with speed and operational simplicity in mind. With a single measurement of 1 second in duration, small volumes of Liquids, Pastes, and Powders can be accurately and precisely measured for thermal conductivity, thermal diffusivity, and specific heat. The THW-L1 utilizes a non-stationary measurement approach and rapid test times to limit convective effects for samples with a wide range of viscosities. The THW sensor consists of a thin heating wire 40 mm in length and is completely inserted into the sample to be tested. The sensor wire is heated using a constant current source (q) and the temperature rise is recorded by monitoring the change in electrical resistance of the wire. The slope (m) from the plot of temperature rise vs. logarithm of time is used in the calculation of thermal conductivity (λ). For liquid samples of high thermal conductivity, the lower the slope. For liquid samples of low thermal conductivity, the higher the slope.

| Models | THW-L1 | THW-L1S | THW-L1E |

| Materials | Liquids and PCMs | Liquids and PCMs | Liquids and PCMs |

| Thermal conductivity (W/m•K) | 0.01 to 2 | 0.01 to 2 | 0.01 to 2 |

| Additional Properties | Thermal diffusivity and specific heat | Thermal diffusivity and specific heat | Thermal diffusivity and specific heat |

| Viscosity range (cP) | 0.001 to 10,000,000 | 0.001 to 10,000,000 | 0.001 to 10,000,000 |

| Sample size (mL) | 20 | 20 | 20 |

| Test time (seconds) | 1 | 1 | 1 |

| Accuracy (Thermal conductivity)* | 2% | 2% | 2% |

| Repeatability (Thermal conductivity)* | 1% | 1% | 1% |

| Temperature range (°C) | 10 to 200 | -40 to 200 | -160 | -40 | 0 to 300 |

| Pressure (bar) | Up to 20 | Up to 20 | Up to 35 |

| External cooling apparatus required | No | Yes | Yes |

| Standard | ASTM D7896-19 | ASTM D7896-19 | ASTM D7896-19 |

*All performance data is verified with ASTM Type II Water (IAPWS)

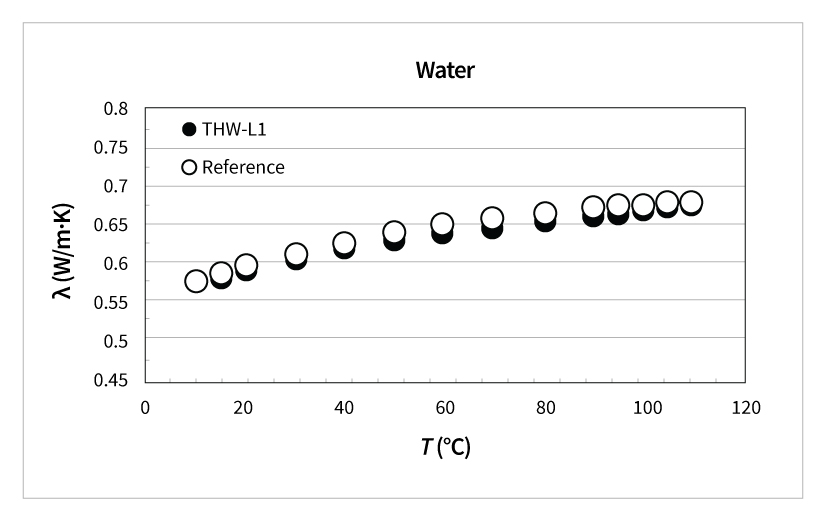

Deviations from reference values:

Water < 2%

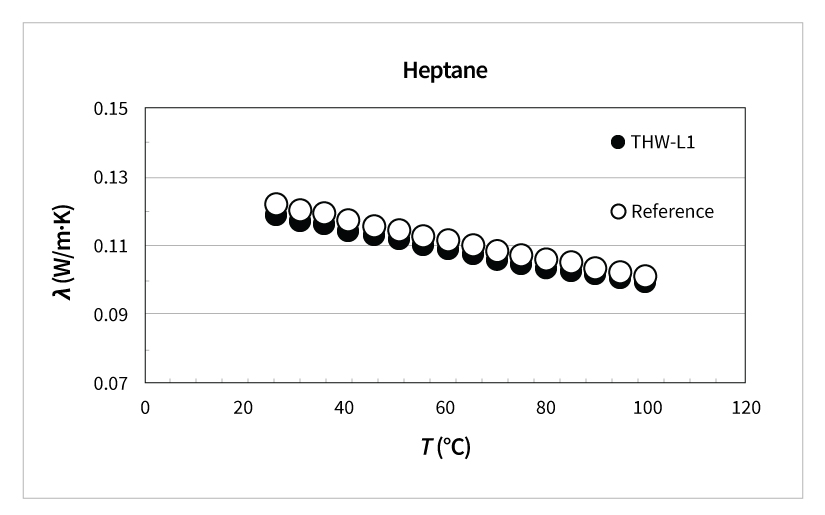

Deviations from reference values:

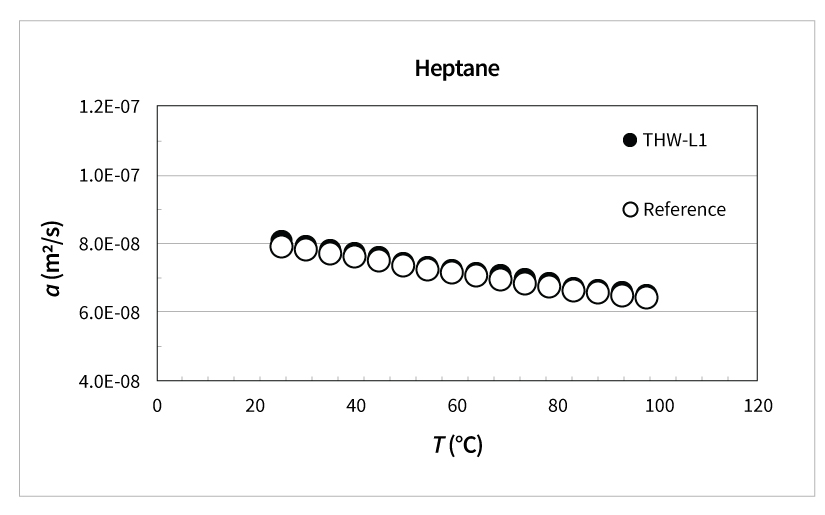

Heptane < 3%

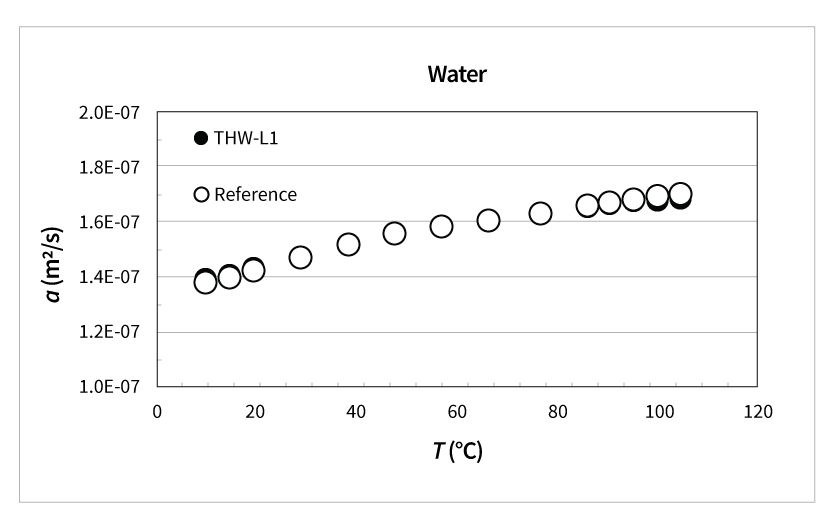

Deviations from reference values:

Water < 2%

Deviations from reference values:

Heptane < 2%

Deviations from reference values:

Water < 2%

Heptane < 5%

Low back pressure was applied to allow measurements over their boiling point.

Deviations from reference values:

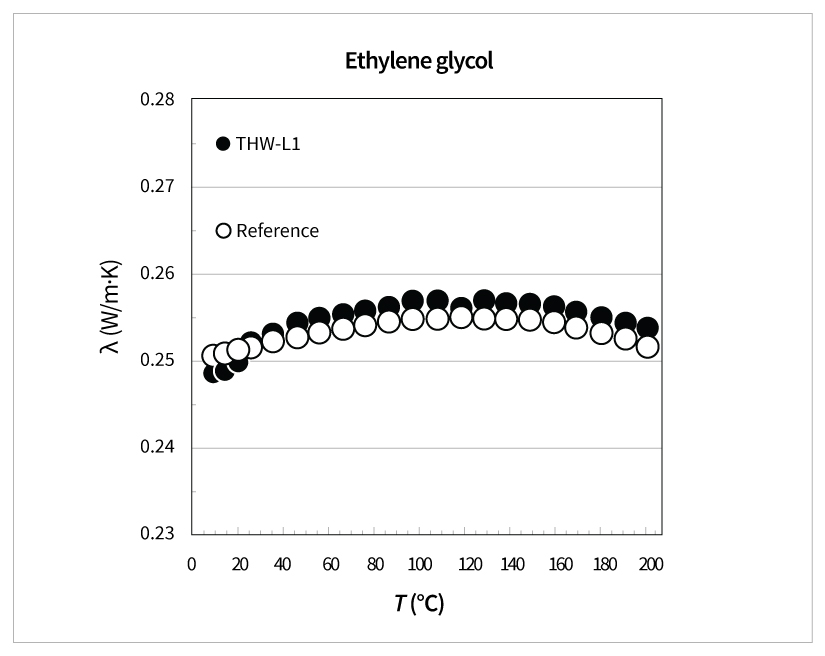

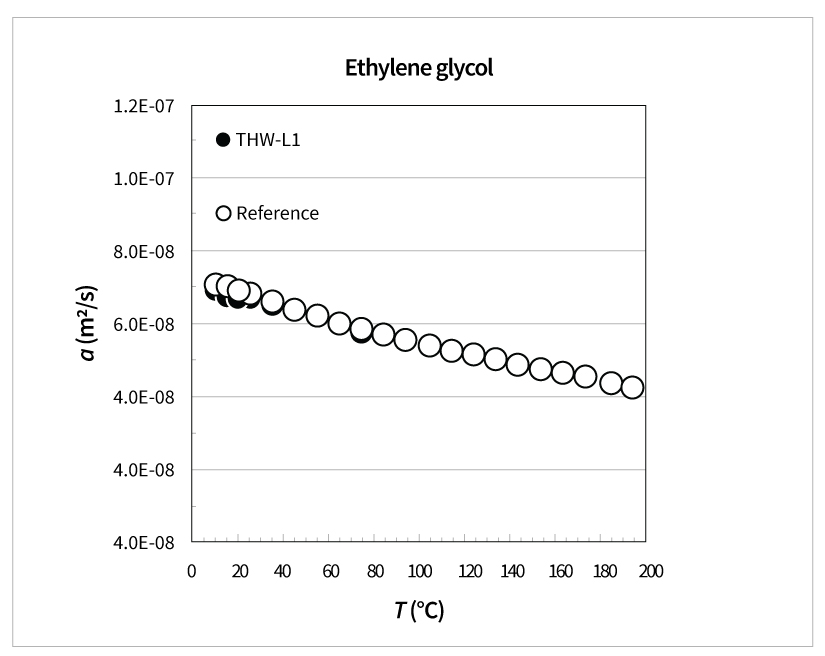

Ethylene glycol < 1%

Deviations from reference values:

Ethylene glycol < 1%

Deviations from reference values:

Ethylene glycol < 2%

Citation:

Lemmon, E.W., Bell, I.H., Huber, M.L., McLinden, M.O. (2018). NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 10.0. National Institute of Standards and Technology, Standard Reference Data Program, Gaithersburg.

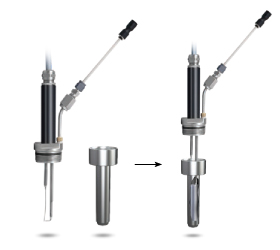

The liquid is poured into the sample cell, the required volume is 20 ml. The THW-L1’s ability to limit convection, using short test times, allows accuracy measurements of a large range of samples, widely varying viscosities. The sample cell can then be back filled to pressures up to 35 bar, for testing liquids past their boiling points.

Approximate Time: 1 minute

For testing with temperature, the liquid cell is inserted into the integrated temperature platform.

Approximate Time: < 1 minute

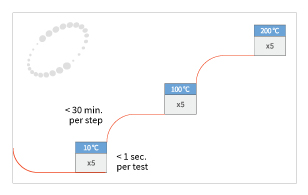

The THW-L1 Software automatically controls isothermal steps of temperature from -150 to 300°C.

Approximate Time: < 1 minute

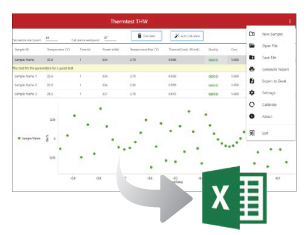

Smart THW-L1 Windows Software verifies quality of results and recommends changes if needed. Results report can be generated, saved, and exported to excel. For convenience results may also be emailed.

Approximate Time: 1 minute

Thermal Conductivity of Suspensions of Carbon Nanotubes in Water

An investigation on the enhancement of the thermal conductivity of water with the addition of multiwalled carbon nanotubes, (C-MWNT). C-MWNT occupied 0.6% of the volume in the test sample for every…

Investigation of the Thermal Conductivity and the Viscosity of Carbon Black Heat Transfer Nanofluids

Seven distinct samples of nanofluids consisting of different concentrations of spherical graphitized carbon black in an ethylene glycol solution were analyzed to determine their thermal and rheological behavior.

Special Phase Change Materials (PCM) with easy to load access. Unique spring design allows sample expansion and contraction, while ensuring sample is in constant contact with THW wire during measurement.

The THW-L1 Ambient density Powder Cell is suitable for basic powder sample testing and ambient pressure.

THW-L1 test cell with screw-type compression system for varying the density of powder samples, can also be used to ensure powders stay in contact with THW wire.

THW-L1 observation sample cell is used for liquids,

powder, and paste testing. The cell has convenient

glass ports for observing what is happening with your sample. Typical applications are phase separation, boiling or particle settling to name a few.

Convenient THW cell mount that can be attached to your THW-L1 for vertical sample loading. Ideal for the Paste/PCM and all Powder Cells.

We are happy to arrange a live demonstration for you!