The apparent thermal effusivity / thermal effusance (W√s/m2K) of various liquids were measured using TPS-EFF (Transient Plane Source-Effusivity) and sample bags.

Transient Plane Source – Thermal Effusivity Meter

TPS-EFF is a portable thermal effusivity meter for textiles with a thermal effusivity measurement range of 35 to 1700 (W√s/m2K) and a temperature range of -10 ºC to 50 ºC. A single measurement can be set to 2 or 10 seconds in duration. The experiment was conducted in accordance with the ASTM D7984-16 standard of testing method as much as possible, keeping in mind that liquids not textiles. Due to the robust nature of thermal effusivity as a value, it was deemed worthwhile to attempt to measure the thermal effusivity of liquids with this method.

Thermal effusivity is most typically measured to predict how ‘cool’ or ‘warm’ a material feels. It has a square root proportionality to the density, thermal conductivity, and specific heat capacity of the material. Highly dense samples of materials with high thermal conductivity and specific heat capacity values have high thermal effusivity values, and this is also the case the other way around.

In non-solid samples, there are more modes of heat transfer than solely conduction. When other heat transfer mechanisms such as convection and radiation are present in the sample, thermal conductance becomes a more appropriate term than thermal conductivity. This makes thermal effusance or effective thermal effusivity more appropriate to use over thermal effusivity in the case of these measurements.

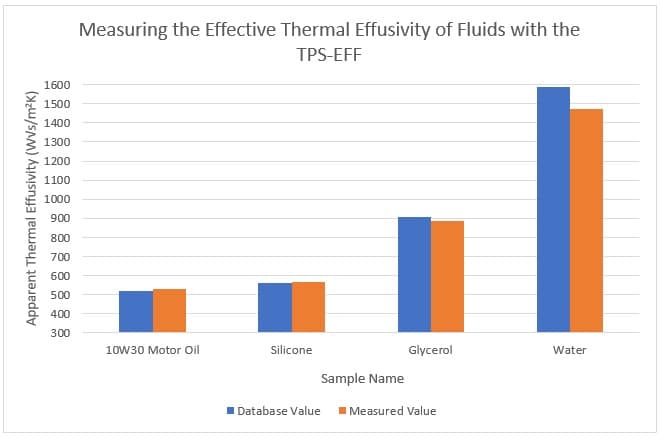

In this experiment, liquids in sample bags were measured for thermal effusance using a TPS-EFF meter and compared to their corresponding value in the materials database, see Figure 1. A test time of 10 seconds was used in the hopes of obtaining a value that minimizes the effect of contact resistance and is more representative of the bulk of the sample, not the sample bag itself. If this is an effective method for measuring the thermal effusance of liquids, the values obtained from measurement should be very close to the database values.

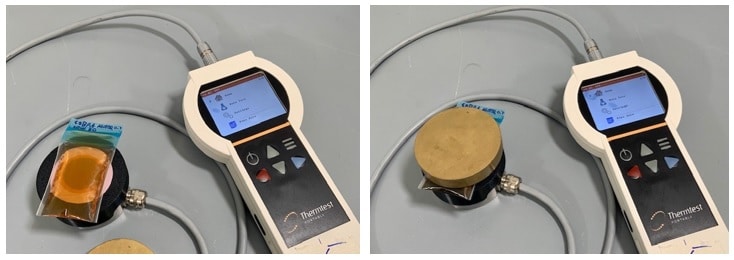

Figure 2. Measuring the thermal effusance of 10W30 motor oil with the TPS-EFF. Left: A sample bag filled with motor oil is placed on the sensor. Right: A weight is placed on the sample bag to ensure adequate contact with the sensor.

Figure 1. A comparison of thermal effusance / effective thermal effusivity between measurements of liquids in sample bags with a touch time of 10 seconds and the Thermtest Materials Database value.

The results indicate that the measured apparent thermal effusivity and known thermal effusivity from the Thermtest database are very similar. A discrepancy of 2% was observed for relatively viscous materials (motor oil, silicone, and glycerol), while a 7% discrepancy between the measured and known value was observed for water. This is likely due to convection in the samples during measurement. A measurement is 10 seconds in duration, allowing ample time for convection to occur in liquids that are low in viscosity. Another source of error is the sample bag itself, although it is comparatively thin to the liquid sample and does not seem to affect the results significantly.

Based on these findings, it appears that the thermal effusance of sufficiently viscous liquids can be accurately measured with the TPS-EFF using this method.

TPS-EFF has a 5% accuracy and a 2% reproducibility, making it a highly accurate and precise instrument for measuring thermal effusivity of textiles and other materials.