To ensure reliable and accurate measurements are achieved using TPS, a benchmark standard material is essential. ARMCO Iron is a long-standing reference for thermal transport property measurements owing to its consistent manufacturing, minimal property variation from sample to sample, and widespread availability.

In the commercial and industrial sectors, ARMCO iron is considered as one of the purest forms of steel (99.9% pure) with consistent properties. In this application sheet, we investigate the thermal transport properties of ARMCO iron.

Figure 1. Measurement Platform Versatile (MP-V)

The TC (W/mK), TD (mm²/s), and VHC (MJ/m³K) of ARMCO iron are measured using Thermtest’s Measurement Platform Versatile (MP-V) equipped with a TPS sensor in a symmetric 3D bulk module. The MP-V is specifically designed to accurately determine TC, TD, VHC and thermal effusivity of solids, liquids, pastes and powders by combining the TPS (ISO 22007-2) and transient hot-wire (THW, ASTM D7896-19) methods. Thermtest’s TPS accommodates a wide range of sensor options compatible with isotropic, anisotropic, and slab materials in both symmetric and asymmetric configurations. For more information about MP-V, please visit Thermtest MP-V .

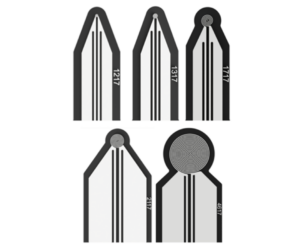

Figure 2. TPS Sensors in a variety of sizes to provide high-precision measurements.

The TPS sensor consists of a thin Nickel foil in a double spiral shape, housed in an electrically insulating film. In a symmetric 3D bulk test, the sensor is firmly placed in between two identical samples with the centers of sensor and samples aligned perfectly. At the beginning of the test, users input the sample dimensions and optimal power and time parameters.

The sensor functions as a power source and a resistance thermometer simultaneously. This means the sensor provides constant power to the sample surface, while recording the temperature rise on the sensor surface over time. The thermal transport properties of the material are then calculated using the material parameters, temperature measurements, the input power and time parameters.

Figure 3. ARMCO Iron samples used for testing.

ARMCO steel, developed by the American Rolling Mill Company (ARMCO) in 1909, is one of the highest grades of pure steel. With its homogeneous ferritic structure and deficient levels of Carbon and other impurities such as Oxygen, Sulphur and Nitrogen, ARMCO iron is used as a primary melting material for casting corrosion-resistant, high-strength steels. Due to its exceptional purity, steel alloys developed from ARMCO steel are very well known for resistance to corrosion, oxidation, and chemical attack.

ARMCO Iron samples of 10mm height and 14mm radius are measured in symmetric configuration using 2117 sensor (3.2mm radius) and 3D bulk module. Optimal measurement parameters of 2s and 500mW are selected to achieve appropriate temperature rise and repeatable results. Using the contact correction, the contact resistance between the sensor and sample is measured and removed during analysis to obtain accurate results.

The thermal conductivity, thermal diffusivity and volumetric heat capacity of the ARMCO iron measured using 2117 sensor are presented in Table 1. From Table 1, it is evident that the thermal conductivity results demonstrate significant similarity to the reported value of 75.17 W/m/K [1] and 74.27 W/m/K [2].

| Temperature (ᵒC) | Thermal Conductivity (W/m·K) | Thermal Diffusivity (mm2/s) | Volumetric Specific Heat (MJ/m3K) |

| 22.4 | 76.679 | 21.751 | 3.525 |

| 76.196 | 21.869 | 3.484 | |

| 76.734 | 21.503 | 3.569 | |

| 75.129 | 22.889 | 3.282 | |

| 75.830 | 22.981 | 3.300 | |

| Mean | 76.114 | 22.199 | 3.432 |

| Standard Deviation | 0.664 | 0.686 | 0.132 |

| %RSD | 0.9 | 3.1 | 3.9 |

ARMCO Iron, 3D Bulk TPS Parameters: 1 sec. 1 W, 23°C, n=5.

ARMCO Iron is a commercially pure form of iron (99.9% pure) with repeatable properties. The ease of manufacturing and highly repeatable values makes it an ideal candidate as a reference material for TPS measurements. In this application sheet, we investigated the thermal properties of ARMCO Iron and found that it is highly conductive with a thermal conductivity of 76.1 W/m/K. The thermal conductivity value measured with 3D TPS technique is compared with two reference values and found to be within 1.3%-2.5% variation of the reported values.

T.W.Watson, H. R. (1964). Thermal Conductivity and Electrical Resistivity of a specimen of ARMCO Iron. National Bureau of Standards, U. S. Department of Commerce.

H.R. Shanks, A. G. (1967). Thermal Properties of ARMCO Iron. Journal of Applied Physics, 2885-2892.

History.8 – The History of Armco Iron. (2018, April). Retrieved from https://thermtest.com/history-8-history-armco-iron

R.P.Tye, D. Hume (2016). Reference materials for thermal transport properties measurements. Journal of Thermal Analysis and Calorimetry.