The apparent thermal effusivity / thermal effusance (W√s/m2K) of natural wood and synthetic wood flooring was measured using TPS-EFF (Transient Plane Source-Effusivity) to determine which sample of synthetic wood flooring feels most like natural wood flooring. The sample that more closely imitates real wood will be the one that customers most want to buy.

Transient Plane Source – Thermal Effusivity Meter

TPS-EFF is a portable thermal effusivity meter for textiles and fabrics with a thermal effusivity measurement range of 35 to 1700 (W√s/m2K) and a temperature range of -10 ºC to 50 ºC. A single measurement can be set to 2 or 10 seconds in duration. The experiment was conducted in accordance with the ASTM D7984-16 standard of testing method as much as possible, keeping in mind that flooring samples are not textiles, although they are quite similar. Due to the robust nature of thermal effusivity as a value, it was deemed worthwhile to attempt to measure the thermal effusivity of flooring with this method.

Thermal effusivity is most typically measured to predict how ‘cool’ or ‘warm’ a material feels. It has a square root proportionality to the density, thermal conductivity, and specific heat capacity of the material. Highly dense samples made of materials with high thermal conductivity and specific heat capacity values have high thermal effusivity values and vice versa. Depending on the situation, one might want a material to feel hot or cold to instill a feeling of comfort to the user. A user would want a winter coat to feel warm in cold weather or a car interior to feel cool in the summer. In the case of flooring, natural wood floors feel like higher quality material than cheap synthetic flooring, which typically have higher effusivity values and feel cooler. The ability to convey a feeling of quality based on thermal effusivity would be of interest to the seller of flooring, who would be able to use this value to produce a material that closely imitates natural wood.

In non-solid samples, there are more modes of heat transfer than solely conduction. When other heat transfer mechanisms such as convection and radiation are present in the sample, thermal conductance becomes a more appropriate term than thermal conductivity. Therefore, thermal effusance or effective thermal effusivity is more appropriate to use over thermal effusivity in the case of these measurements.

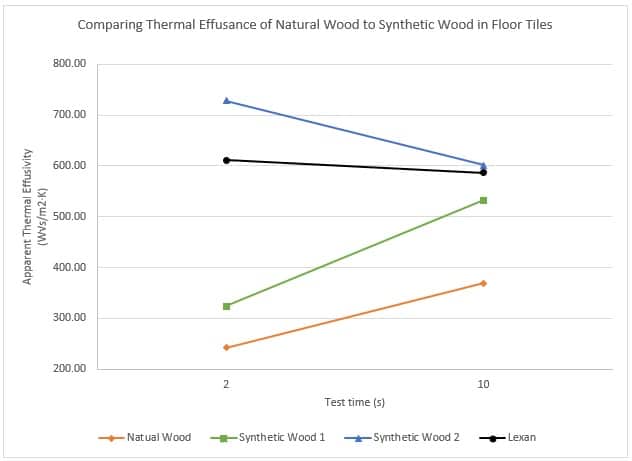

In this experiment, one sample of wood and two samples of synthetic wood (Figure 1) were measured for thermal effusance using a TPS-EFF meter, see Figure 1. Test times of 2 and 10 seconds were used to simulate both short and long touch times to determine how the imitation wood feels when compared to the feel of natural wood. It is expected that synthetic wood flooring that more closely resembles the feeling of natural wood will be preferred by a customer interested in buying flooring.

Figure 1. Three flooring samples for effusivity testing.

Left: Natural wood. Center: Synthetic wood #1. Right: Synthetic wood #2.

Figure 2. A comparison of apparent thermal effusivity or thermal effusance values of one natural wood flooring sample with two synthetic wood flooring samples. Samples were tested at 2 and 10s touch times to simulate the feeling of touching the flooring for both short and long periods of time, as the feeling will change as heat penetrates through the surface layer of the flooring. Lexan was included as a homogeneous material control, where little difference between 2 and 10 second test times is expected to occur in the effusance values.

The results indicate that the first sample of synthetic wood yielded thermal effusance values more similar to natural wood than the second sample of synthetic wood. For a short test time that simulates a customer touching a sample tile of flooring, the thin insulating layer on synthetic sample 1 appears to grant a warm feeling to the flooring panel, like that of wood. The synthetic sample 2, with its thin layer of vinyl, yielded a larger effusance value, indicative of a cold feeling that is not characteristic of wood. One can imagine a scenario where a customer is trying to decide between two types of synthetic flooring and decides to purchase the type of flooring that feels more like wood, as this gives a feeling of luxury that the alternative does not provide.

TPS-EFF has a 5% accuracy and a 2% reproducibility, making it a highly accurate and precise instrument for measuring thermal effusivity of textiles and other materials.