The Measurement Platform-2 (MP-2) is an advanced meter with a unique selection of transient thermal conductivity sensors for a variety of applications, with a focus on primary measurements. The transient thermal conductivity sensors share similar principles of operation. The sensor wire is heated using a constant current source (q), and the temperature rise is recorded by monitoring the change in electrical resistance of the wire (THW and EFF) or by a resistance temperature detector device (TLS). For samples of high thermal conductivity, resistance increases more slowly over time; for samples of low thermal conductivity, resistance increases more quickly over time.

Figure 1. Thermtest MP-2 Thermal Conductivity Meter

Thermal conductivity MP-2 users benefit from the convenience and accuracy gained when using primary testing methods. The MP-2 controller auto-detects the connected sensor and loads corresponding testing parameters. Measurements are easily performed with the smart on-board software and transferred to a computer with an included Windows utility program.

Figure 2. Thermtest THW-S sensor for use with the MP-2 portable meter.

The THW-S sensor is one of the many sensors offered with the Thermtest Portable Measurement Platform (MP-2). This sensor offers simple yet accurate measurements of homogenous insulation and soft materials from 0.01 to 2 W/m·K via the transient hot-wire method.

The THW-S has a detect current setting that determines the appropriate amount of current to apply based on a test measurement. By reading the result of the test measurement, a current will be set that results in an optimal temperature rise of the sample during testing.

Gaskets are a type of mechanical seal between two or more surfaces, generally to prevent leaks of liquid or gas. Depending on the application, gaskets can be made of different materials but are often made from rubbers. For this application sheet, four types of rubber material were measured: ethylene propylene diene monomer (EPDM), polyurethane (40A and 60A durometer), neoprene (30A and 40A durometer), and styrene butadiene rubber (SBR).

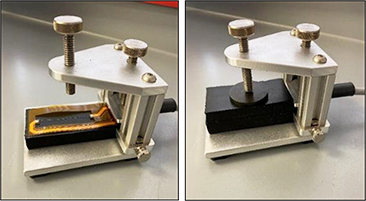

Figure 3. Set-up of the sample holder and THW-S sensor between two pieces of neoprene rubber

figure 4.MP-2 handheld with THW-S sensor

Table 1. Average results (n=5) of measuring various gasket materials with the Thermtest THW-S sensor at room temperature.