In the construction industry, thermal conductivity of insulation materials plays an important role. For most homeowners, the winter months are dreadful, as heating costs rise. Various means of insulations exist, however, the most commonly used are fibrous in nature, such as fiberglass and stone wool. Fibrous insulations trap air between the fibers (glass, stone, etc.), to lower the thermal conductivity of the insulation. Fiberglass, the most commonly used insulation, is the product of minute glass fibers spun into a wool-like substrate. Because glass is inorganic, the insulation is able to withstand temperatures on a scale of 600˚C, which aims to reduce the spread of fire.

Recently, building contractors have been using a more eco-friendly thermal insulator; stone wool. The stones used in this insulation are a by-product of volcanic activity, and are manufactured into a wool-like batting. Due to the hydrophobic nature of stone wool, this insulation does not harbor, or help the growth of mold and bacteria, making your home a safer and healthier environment. Stone wool is also inorganic, and therefore fire resistant. However, due to a more dense nature than fiberglass insulation, stone wool insulation can withstand higher temperatures, on a scale of 1100˚C.

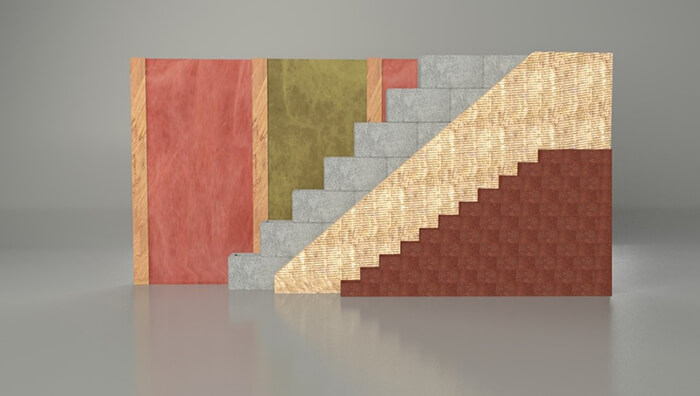

Figure 1. Pictured are the layers of building materials encompassing a wall. Bottom right, outer brick façade, followed by a layer of dense insulation, cinder blocks, and the inner wall structure, composed of two-by-four studs and batting insulation, stone wool or fiberglass.

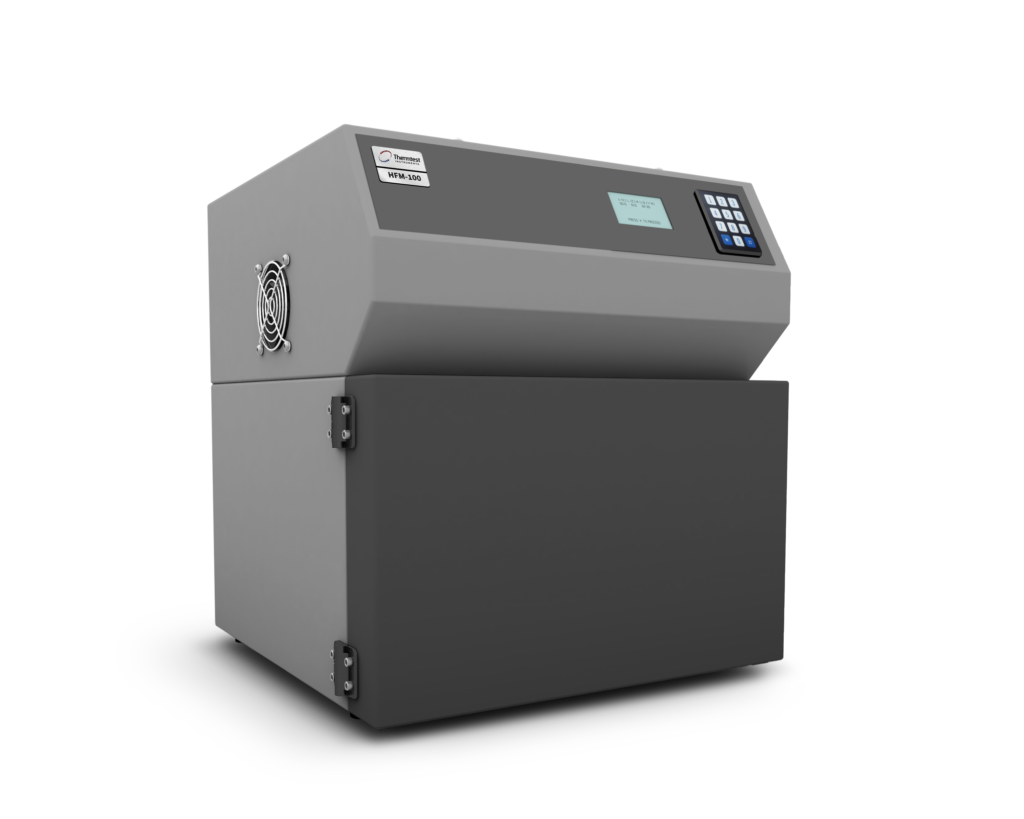

The Thermtest Heat Flow Meter (HFM) is a steady-state, one dimensional heat transfer system, that measures the thermal conductivity and thermal resistivity of flat slab insulating materials, such as foams, solids and textiles (Figure 2). In accordance with ASTM C518-15, the Heat Flow Meter apparatus can measure materials with thermal conductivities ranging from 0.005 to 0.5 W/m·K. To mimic in-situ applications, the HFM is capable of testing materials over a temperature range of -20°C to 70°C.

Figure 2. The Thermtest Heat Flow Meter for thermal conductivity testing of large, flat slab insulating materials

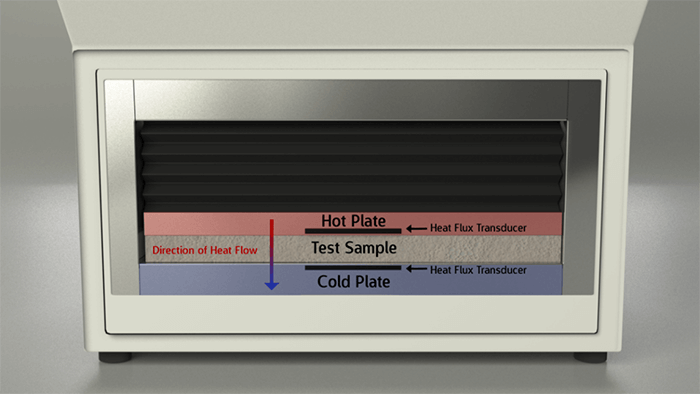

Per ASTM C518-15, a calibration measurement must be performed on a Standard Reference Material of similar size and thermal conductivity, prior to performing a test measurement. The test sample is then placed within the HFM chamber and the parallel plates are set to adjust to the manufacturer’s specified installation thickness. A steady-state, one dimensional heat flux through the specimen is established, by two parallel plates, one on either side of the specimen, and a temperature gradient is set within the software (ex: 30 ºC and 10 ºC) (Figure 3). A temperature gradient such as this, is set to mimic the heat loss from the interior, to the exterior home environment.

Figure 3. View from inside the Heat Flow Meter door. A one-dimensional heat flux through the test specimen is established by parallel plates (red and blue), at a desired temperature gradient.

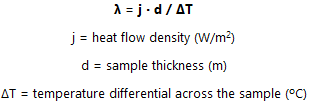

Although the HM chamber can accommodate for a sample as large as 12” X 12” X 4”, the heat flux transducers are positioned in the center of the upper and lower plates (Figure 3), allowing for any sample shape and size above 6” X 6” X 0.4”. By appropriate calibration of the heat flux transducer(s) with standard reference materials, and by measuring the plate temperatures and separation, Fourier’s law of heat conduction is used to calculate thermal conductivity (λ):

Table 1. The thermal conductivity measurements of stone wool and fiberglass batting insulation, using the Thermtest Heat Flow Meter.

| Material | Thermal Conductivity (W/mK) |

| Stone Wool Batting Insulation | 0.0364 |

| Fiberglass Batting Insulation | 0.0430 |

This experiment outlines the importance of research when it comes to the selection of insulation. A proper knowledge of not only the cost and thermal conductivity of insulations, but other characteristics such as water permeability and fire performance, is also key. The Heat Flow Meter thermal conductivity results, of both the stone wool and fiberglass insulations, as compared to the manufacturer’s stated conductivity, were within the stated accuracy of the Heat Flow Meter (3%). As can be seen, users can expect a high degree of accuracy, with this ASTM traceable technique.

The Thermtest Heat Flow Meter (HFM) provides users with the ability to measure thermal properties of larger, flat slab specimens ranging in thermal conductivities from 0.005 to 0.5 W/m∙K. The Heat Flow Meter is capable of measuring the steady-state heat transfer properties of foams, solids, and textiles.

References:

ASTM C518-15, Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus, ASTM International, West Conshohocken, PA, 2015.

Karamanos, A., Hadiarakou, S., and Papadopoulos, A. M. 2008. The impact of temperature and moisture on the thermal performance of stone wool. Energy and Buildings, 40: 1402 – 1411.

Al-Homoud, M. S. 2005. Performance characteristics and practical applications of common building thermal insulation materials. Building and Environment, 40: 353 – 366.

http://www.roxul.com/products/comfortbatt/

http://insulation.owenscorning.ca/homeowners/insulation-products/pink-fiberglass-r12.aspx