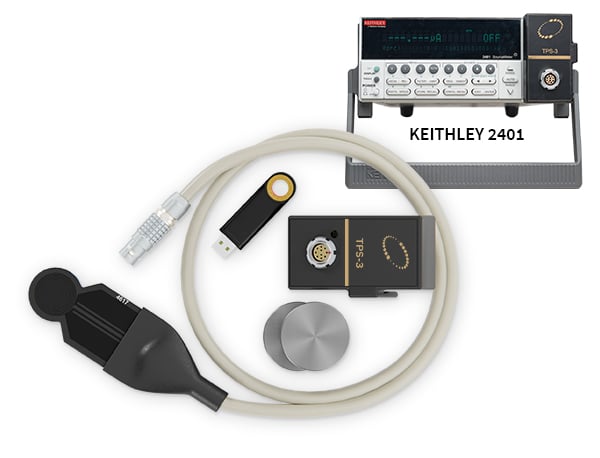

A transient plane source (TPS-3) for testing the thermal conductivity, thermal diffusivity and specific heat of solids, pastes and powders for customers with a limited budget.

Best For Solids, Powders and Pastes

Test Method

Temperature

Range

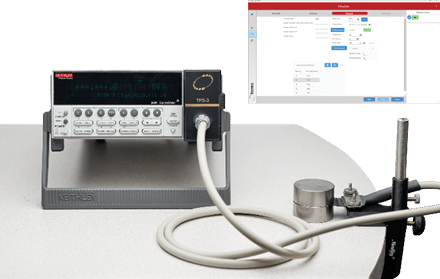

The basic theory is that the sensor, which is placed between two pieces of the same sample, is electrically connected to a power supply and sensing circuit. A current passes through the sensor and creates an increase in temperature recorded over time. The heat generated is then diffused into the sample at a rate dependent on the thermal transport characteristics of the material.

| Materials | Solids, pastes, and powders |

| Thermal conductivity | 0.03 to 70 (W/m•K) |

| Additional properites | Thermal diffusivity and specific heat |

| Sensor diameter (mm) | 20 |

| Smallest sample size (mm) | 40 diameter x 5 length |

| Largest sample size | Unlimited |

| Test time (seconds) | 10 to 160 |

| Accuracy (Thermal conductivity) | 5% |

| Repeatability (Thermal conductivity) | 2% |

| Temperature range (°C) | 10 to 80 |

Standard 20 mm diameter TPS Double Spiral Sensor (Model 46171).

Room temperature measurement of NIST EPS 1453 was 0.032 W/m·K, RSD 0.65%, compared to expected value of 0.0332 W/m·K. Accuracy of 3.6%.

Room temperature measurement of Pyrex Glass was 1.17 W/m·K, RSD 1.5%, compared to expected value of 1.15 W/m·K. Accuracy of 1.7%.

Room temperature measurement of Stainless Steel 316 was 13.81 W/m·K, RSD 1.2%.

We are happy to arrange a live demonstration for you!