This application will measure the thermal conductivity of neoprene and describe how the thermal properties of neoprene change with different durometers.

Neoprene was originally developed as an oil-resistant replacement for rubber, however, its durability, elasticity, insulative capabilities, resistance to moisture, and resilience against outdoor environments have allowed it to be used in many more applications. The function of neoprene is largely determined according to its durometer (whether the neoprene rubber is hard or soft), which affects its physical, mechanical, and thermal strength. But does durometer have an effect on the thermophysical properties of neoprene?

Three samples of neoprene rubber (30A, 40A, and 60A) were measured for thermal conductivity (W/m·K), thermal diffusivity (mm²/s), and volumetric specific heat (MJ/m³K) using the MP-1 Transient Plane Source (TPS) Method: Standard Module. The MP-1 with TPS Standard Module is used to measure the average or bulk thermal conductivity and thermal diffusivity of isotropic materials.

Neoprene is a family of synthetic rubbers that exhibit good chemical stability and maintain flexibility over a wide range of temperatures. Neoprene exists as a solid rubber as well as in latex form. Generally, neoprene more resistant to degradation compared to natural or other synthetic rubbers. Neoprene is also waterproof and corrosion resistant, which makes it resistant to a range of environmental factors. This makes neoprene well suited for applications such as gaskets, hoses, and coatings. Neoprene is highly thermally resistant. Even at extreme cold and heat temperatures, neoprene will not physically degrade, making it better suited for long term use over other similar rubbers.

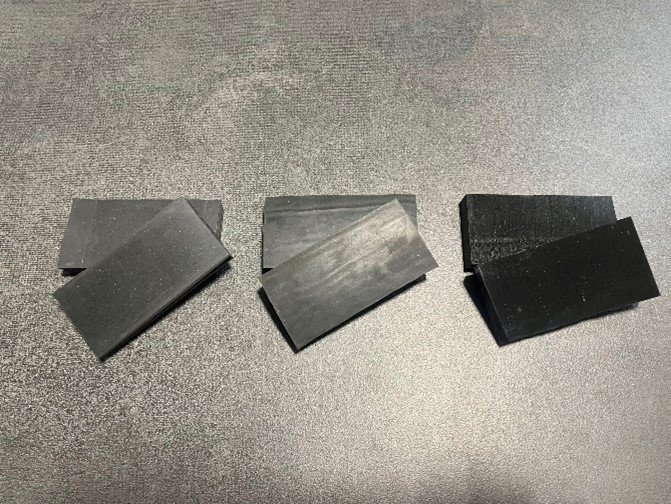

Figure 1. Neoprene 30A (left), 40A (middle), and 60A (right).

The MP-1 is designed to test the absolute thermal conductivity, thermal diffusivity and specific heat of solids, liquids, pastes and powders with the powerful combination of the transient plane source (TPS, ISO 22007-2) and transient hot-wire (THW, ASTM D7896-19) methods. The Standard Module is used to measure the average or bulk thermal conductivity and thermal diffusivity of isotropic materials.

Figure 2. Measurement Platform-1 (MP-1) with Transient Plane Source Temperature Platform (TPS-TP).

The neoprene durometer rating determines its application, durability, flexibility, and pliability. When considering using neoprene for an application, it is important to determine and consider its durometer. Harder neoprene with durometer ratings of 60A or 70A are better suited for heavy duty applications while soft neoprene such as 30A or 40A durometer neoprene is better suited for applications where compressibility is valued. The durometer of neoprene affects its mechanical and physical properties, thermal properties, and makes them suitable for different uses. In this application, we measured three different samples of neoprene of different durometers and compared their thermal conductivities.

The samples were measured in the symmetric configuration with the standard 6.4 mm radius sensor (3317-1). Optimal sample parameters of 160s and 20mW were determined using the intelligent transient plane source (iTransient) application that determines the appropriate sensor, test time, and power to use for each individual sample based on sample properties and dimensions.

Table 1. Thermal properties of neoprene measured with MP-1 at 23ᵒC.

| Sample | Thermal Conductivity (W/m·K) | Thermal Diffusivity (mm2/s) | Volumetric Specific Heat (MJ/m3K) |

| 30A Durometer | 0.237 | 0.109 | 2.174 |

| 40A Durometer | 0.232 | 0.135 | 1.722 |

| 60A Durometer | 0.204 | 0.102 | 2.093 |

n=5, 6.4 mm (3317-1), 23ᵒC, 160s, 20mW.

Neoprene is popular for its diversity of applications because of its durability, flexibility, and insulative properties. The type of application that neoprene is used for is often influenced by the durometer that the neoprene is, as this would significantly affect the thermal, mechanical, and physical properties of the neoprene. As we found in this application, the thermal conductivity of neoprene decreases with greater durometer.