The Thermal Effusivity (W√s/m2K) of two fabric samples, both with moisture-wicking properties, were compared against each other in a performance test. A sample of generic athletic wear was compared to a sample of fabric designed to have superior moisture-wicking properties. The samples were measured using TPS-EFF (Transient Plane Source-Effusivity) at different moisture levels.

TPS-EFF is a portable thermal effusivity meter for textiles with a thermal effusivity measurement range of 35 to 1700 (W√s/m2K) and a temperature range of -10 ºC to 50 ºC. A single measurement can be set to 2 or 10 seconds in duration. The experiment was conducted in accordance with the ASTM D7984-16 standard of testing method.

Thermal effusivity is most typically measured to predict how ‘cool’ or ‘warm’ a textile feels. It has a square root proportionality to the density, thermal conductivity, and specific heat capacity of the material. Dry fabrics often contain pockets of air between the strands, resulting in thermal effusivity values that are typically low. When dry fabrics are exposed to moisture, the air is replaced by water, which has a much higher thermal effusivity. This will cause the fabric to exhibit a higher thermal effusivity value when wet, making it feel ‘cooler’.

In this experiment, the thermal effusivity of two fabric samples were measured at varying moisture levels using TPS-EFF for a touch time of 2 seconds. Higher levels of moisture mean higher water saturation in the fabric. Therefore, measurements at higher levels of moisture should yield higher effusivity values compared to thermal measurements when the fabric is dry.

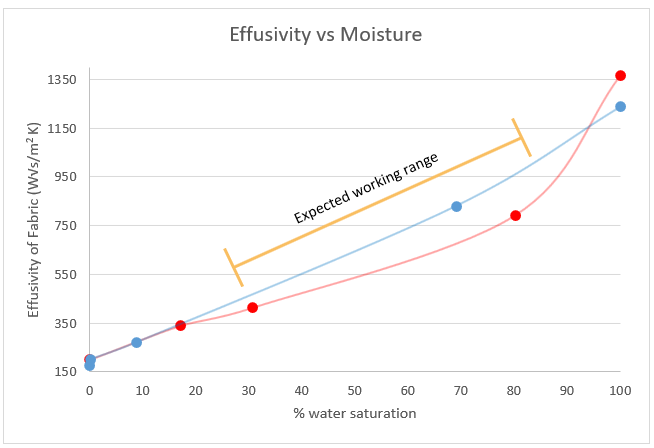

Figure 1. Thermal effusivity values of a generic athletic fabric (red) and a fabric with superior moisture-wicking properties (blue) plotted against moisture level (% water saturation) with a touch time of 2 seconds.

As expected, the results indicate that the effusivity of the fabric increases with higher moisture levels, due to air (low thermal effusivity) being replaced by water (high thermal effusivity). When comparing the performance of the two fabrics, it is important to consider that the typical operating conditions of these fabrics is around 60% water saturation. Under these conditions, the wearer of the fabric is expected to undergo periods of physical strain and elevated body temperature, causing discomfort.

The purpose of these fabrics is to provide comfort to the wearer with a feeling of coolness, which is measured as high thermal effusivity. It can be observed from Figure 1 that in the range of roughly 20 to 90 percent water saturation, the moisture-wicking fabric outperforms the athletic wear fabric. Another interesting property to note is that the moisture-wicking fabric is designed to maintain a higher average percent moisture than other fabrics, granting the user a stronger sensation of coolness without feeling wet.

Figure 2. TPS-EFF sensor placed on top of a fabric sample to record thermal effusivity.

TPS-EFF has an accuracy better than 5% and a reproducibility better than 2%, making it a highly accurate and precise instrument for measuring the thermal effusivity of textiles and other materials.