May 3, 2024

July 7, 2022

June 24, 2022

January 24, 2022

October 28, 2021

July 8, 2019

November 26, 2018

September 22, 2017

June 9, 2017

September 27, 2017

July 24, 2017

September 22, 2017

September 27, 2017

November 26, 2018

January 30, 2019

Little is known of the origins of Lee and Charlton’s method of thermal conductivity determination, the earliest mention of their work was found to be in the Philosophical Magazine’s 41st Volume, 1896(1). This method, commonly known as Lee’s Disc method, is a simple and effective way to calculate the thermal conductivity of materials with low thermal conductivities. With the use of easy-to-find parts, anyone can assemble and operate a Lee’s disc apparatus with the goal of thermal conductivity calculation. Ultimately Lee’s Disc method will provide a better understanding of how to calculate thermal conductivity.

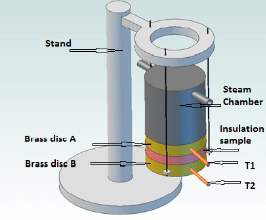

In order to obtain accurate readings, the brass discs should be wrapped in a thermal insulator such as cotton, felt or plastic. Loss of heat by conduction and convection with the environment (air) can skew the results obtain thus using an insulating material where appropriate is important in order to obtain proper results using Lee’s Disc method.

Heat Flow Rate (Q) = k ⋅ A ⋅ (T1-T2) / d

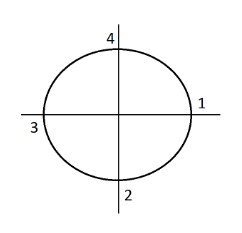

Cross-sectional Area = πD2 / 4 OR πr2

Rate of heat loss (Q) = m ⋅ c ⋅ (dT/dt)

Specific heat capacity of Brass: 377 Joules/Kilogram-Kelvin

Steady-State = Heat entering the system is the same as the heat exiting the system OR no change in temperature (by more than 0.5°C) for 10 minutes.

| Materials Required | Price | Location of Purchase |

|---|---|---|

| Brass disc (2’’ by 0.5’’ = 50mm by 13mm) x 2 | 20$ x 2 = 40$ | Speedymetals.com |

| Lab Stands | 11$ | Amazon |

| Vernier Caliper | 10$ | Amazon |

| Steam Generator | 100-110$ or maker your own | Amazon |

| Steam Chamber | Make your own OR any Can made of a metal with high thermal conductivity* | |

| Ring Clamp (minimum 2’’ = 50 mm) | 10$ | Fisher Scientific |

| Cord (32’’-4’ = 820 – 1200mm) | 100’ for 6$ | Amazon |

| Balance | 20$ | Amazon |

| Thermometers x2 | 10$ x2 = 20$ | Amazon |

| Two Channel Thermocouples (optional) | 30$ | Amazon |

| Bolts x4 (bolt diameter smaller than ½ the width of the brass disc) | Various prices as low as 0.6$ per Bolt | Digi-Key |

| Insulating material (cotton, felt, plastic) | 9$ | Amazon |

| Thermal Grease | 4$ | Amazon |

| Total | 132.4-247.4$ |

*Metals with high thermal conductivity include Aluminum, Copper and Silver. Others can be found in the material database*

The Rate of heat transfer at steady state through a given material is given by the following equation

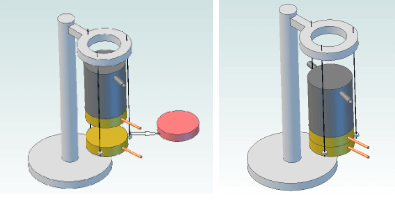

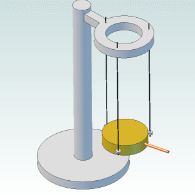

The rate of cooling of at steady state temperature is given by this equation

Since at steady state, the amount of heat entering a system is the same as the amount of heat leaving a system, the following equation may be produced

The Thermal Conductivity constant may be isolated to produce the following

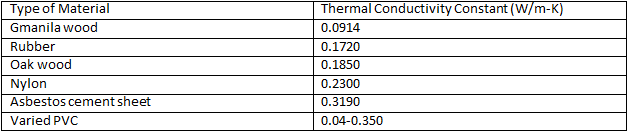

Once all the data has been collected and the thermal conductivity of your sample calculated, the results may be compared to data obtained from highly specialized labs.

*Thermal Conductivity values are taken from the Thermtest thermal properties database, for more Thermal Conductivity values visit: https://thermtest.com/materials-database

Opposite to the Searle’s Bar experiment, Lee’s disc method is designed to calculate the thermal conductivity of primarily thermal insulators such as polystyrene. A thin, large surface area sample is used in the determination of thermal conductivity in order to quickly reach steady state. With a budget of between 150-250$, anyone can test the thermal conductivity of insulating materials.

Web Resources for further information:

https://thermtest.com/thermal-resources/build-your-own/searles-apparatus

https://thermtest.com/history-6-lees-disc-method/

http://iosrjournals.org/iosr-jmce/papers/vol3-issue1/F0315360.pdf?id=2586

To make your own simulation:

https://thermtest.com/thermal-resources/energy2d-heat-transfer-simulations/

For the more technological savvy, certain components of this experiment may be made at home. These components include the steam chamber, steam generator and two channel thermometer.

In order to make a steam chamber all that is required is some metal cylinder with thin walls. The metal used should have a relatively high thermal conductivity (safe bets: Aluminum, Copper). The height of said cylinder should be shorter than the area available above the upper brass disc and should cover the cross-sectional area of the upper brass disc. Two holes must be made in either side of the cylinder (one of the steam inlet and one for the steam outlet).

In order to make a steam generator all that is required is a hot plate, metal container full of water and an air tight lid with a hole large enough for tubing. It is important to note that the airtight seal will produce a closed system and pressure could build with faulty tubing. The tubing will be connected to the steam inlet hole in the steam chamber.

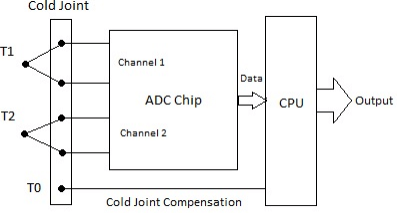

Below is an appropriate design of a two channel thermometer capable of auto-recording the temperature.

The metal plates temperature signal from thermocouples could be read by ADC chips like ADS1248 or MCP3424, and then the digital value would be sent to a CPU like ARM cortex 0. Do remember the thermocouples need cold joint compensation, this could be completed by a thermistor or IC temperature sensor like DS18B20 at thermocouples’ cold joint. The CPU can record the temperatures along with time and then, display, store, or send the recorded data to a computer.

Thermtest is furnishing this item "as is". Thermtest does not provide any warranty of the item whatsoever, whether express, implied, or statutory, including, but not limited to, any warranty of merchantability or fitness for a particular purpose or any warranty that the contents of the item will be error-free. In no respect shall Thermtest incur any liability for any damages, including, but limited to, direct, indirect, special, or consequential damages arising out of, resulting from, or any way connected to the use of the item, whether or not based upon warranty, contract, tort, or otherwise; whether or not injury was sustained by persons or property or otherwise; and whether or not loss was sustained from, or arose out of, the results of, the item, or any services that may be provided by Thermtest.