October 9, 2015

Lee’s Disc method is used to measure the thermal conductivity of a poorly conducting material, such as glass, wood, or polymer. There is little information about the origin of the method, although it was first reported around the year 1898 by English scientist Lee. This was one of the earliest methods used to measure thermal conductivity that gave reliable results, and is a steady state method. Steady state methods are ones where the experimental setup must reach equilibrium before any calculations can be made. In comparison, transient methods are ones where equilibrium is not required before calculations are made, as calculations are made from temperature versus time curves plotted during heating.

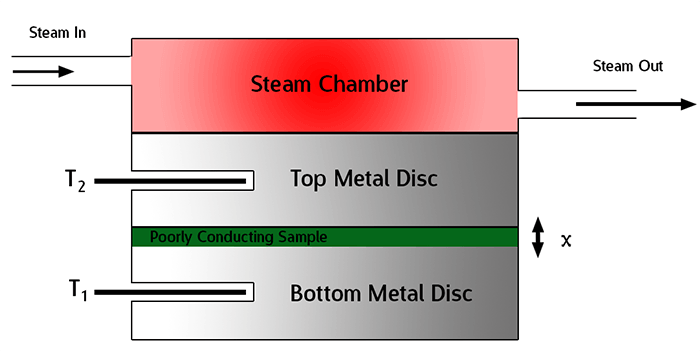

Experimental setup for Lee’s Disc method is quite simple and involves the use of two metal discs (usually brass), a steam chamber, the sample to be measured and two thermometers to measure the temperature gradient. The sample is placed in between the two metal discs (the thermometers are inserted into the metal discs) and the steam chamber is placed on top of the top metal disc. The whole setup is suspended in air so any other conduction effects are removed, although convection is a key factor in calculations. See Figure 1 for experimental setup.

Figure 1. Experimental setup for Lee’s Disc steady-state thermal conductivity measurement.

In the experiment, water is heated to produce steam, which is then pushed through a steam chamber which is directly above one of the metal discs with a thermometer in it. This steam causes the metal disc to heat up and transfer heat to the poor conductor that is being tested. The poor conductor in turn transfers heat to the bottom metal disc, which loses heat to convection. After a certain time, each of the two metal discs will have reached a steady temperature. The two temperatures are different and are used to calculate the thermal conductivity. At equilibrium, the amount of heat transferred from the poor conductor to the bottom disc is equal to the heat lost by that disc due to convection.

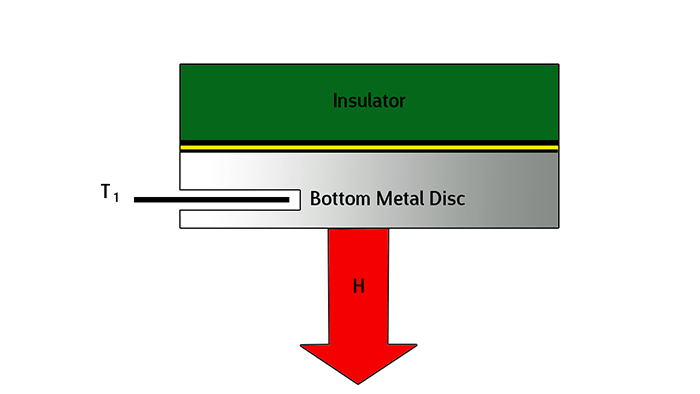

Once the setup has reached thermal equilibrium and the temperature of each disc is recorded, the steam chamber is removed along with the top metal disc and poor conductor. The steam chamber is then used to heat the bottom metal disc directly until it is around 10 degrees above its equilibrium temperature. An insulating material (not necessarily the poorly conducting material being tested) is then placed on top of the bottom metal disc, and the disc is allowed to cool to room temperature, while the temperature is being recorded with respect to time. This cooling curve will allow the cooling rates at various temperatures to be determined, thus the cooling rate at the equilibrium temperature can be determined and this value will allow the calculation of thermal conductivity of the poor conductor.

Figure 2. Once the setup has reached equilibrium, the bottom disc is allowed to cool to room temperature (by loss of heat to convection) in order to plot a temperature versus time curve.

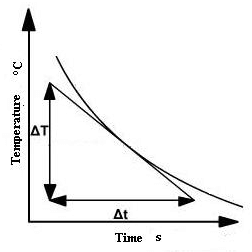

Figure 3. Cooling curve for the bottom metal disc. From this curve, the cooling rate can be determined at a specific temperature (equilibrium temperature of the bottom metal disc) and then used to calculate thermal conductivity.