Bulk Measurement of Thermal Conductivity, Thermal Diffusivity and Specific Heat

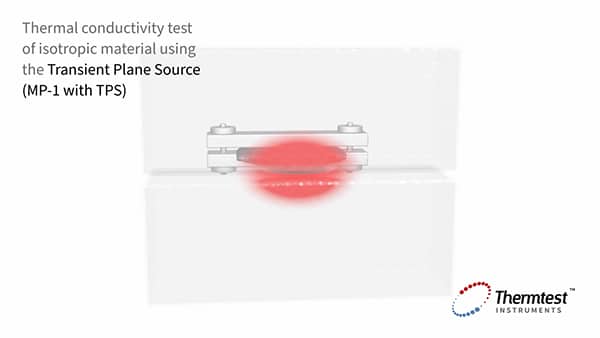

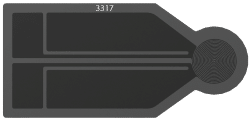

The TPS (Transient Plane Source) Thermal Conductivity Analyzer utilizes a sensor element in the shape of a double spiral (DS).

Transient Plane Source (TPS) Sensor

This TPS sensor acts both as a heat source for increasing the temperature of the sample and a “resistance thermometer” for recording the time dependent temperature increase. In most cases the sensor element is made of a 10 μm thick Nickel-metal double spiral, with precisely designed dimensions (width, number of windings and their radii). This spiral is supported by a material to protect its particular shape, give it mechanical strength and keep it electrically insulated. The polyimide “Kapton” is such a material, which can be used throughout the temperature range from -160 to 300°C. The TPS follows ISO 22007-2.

The encapsulated Ni-spiral sensor is then sandwiched between two halves of the sample (solid samples), or embedded in the sample (powders, liquids). During a pre-set time, 400 to 600 resistance recordings are taken, and from these the relation between temperature and time is established. A few parameters, like the “Output of Power” to increase the temperature of the spiral, the “Measuring Time” for recording 400 to 600 points and the size of the sensor are used to optimize the settings for the experiment. Starting points representing contact resistance between the sensor and sample may be removed manually or with the use of the proprietary contact analysis. This testing can be done in the standard two-sided or single-sided formats.