June 3, 2024

Imagine holding the key to unlocking a material’s deepest thermal secrets. The Transient Plane Source (TPS) method acts as that key, offering a powerful and versatile technique for measuring a material’s ability to conduct heat—its thermal conductivity (TC). This non-destructive approach goes beyond simply measuring TC. It delves into the heart of heat transfer, providing insights into how quickly heat flows through a material, a property known as thermal diffusivity.

Exploring the TPS method’s functionalities, applications, and unique advantages over other methods reveals its versatility. At the heart of this technology is the TPS sensor, a double-spiral disc that acts as both a heat source and a thermometer. By applying a short burst of heat and meticulously recording its dissipation, the secrets of a material’s thermal behaviour are unlocked.

However, the TPS method is not a one-size-fits-all solution. There are various modules available, from the standard module for bulk materials to the thin-film module for delicate films and coatings. Additionally, the TPS method effectively addresses the challenge of measuring anisotropic materials that exhibit different thermal conductivities in different directions.

By the end of this blog, you’ll gain a comprehensive understanding of the TPS method and its potential to revolutionize your approach to thermal management.

The transfer and transformation of heat energy are found in a wide range of applications, from the gentle flicker of a candle to the intense heat used for welding metal parts and from sizzling electric stoves to intricate power electronics. Understanding and quantifying heat transfer and its associated properties is critical to designing and developing efficient systems, from everyday home appliances to cutting-edge technologies.

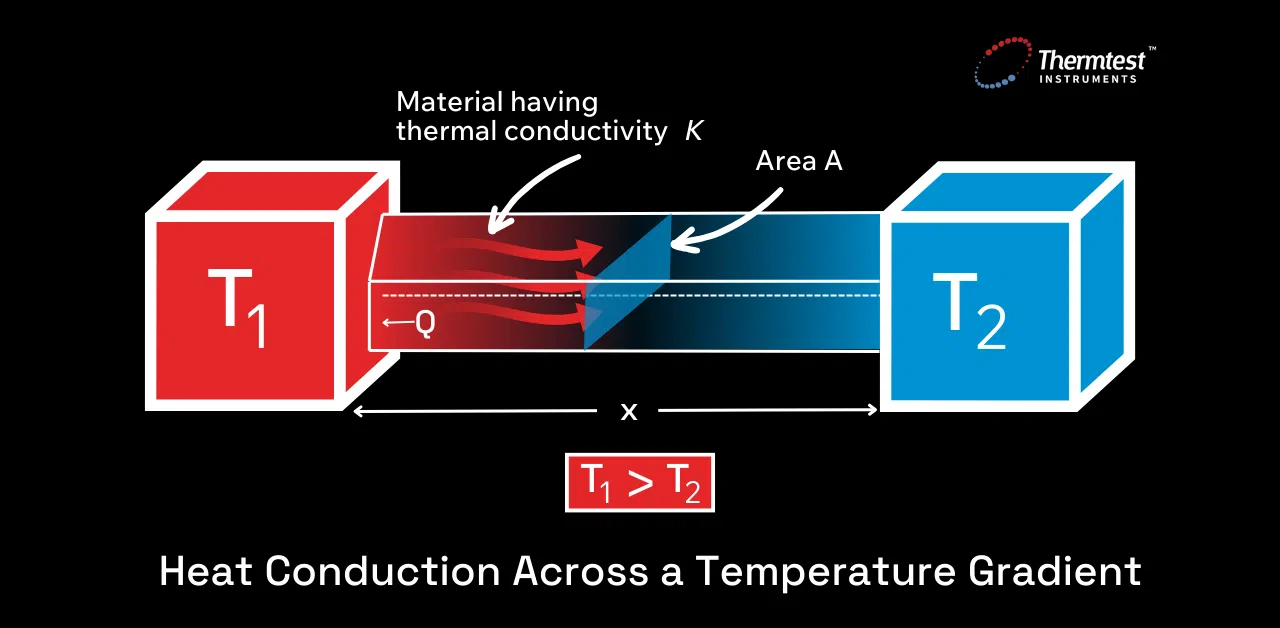

Thermal conductivity defines a material’s ability to transfer heat energy when subjected to a temperature gradient. TC provides a quantitative framework to determine the “ease” or “difficulty” of moving heat across a system. For example, heat sinks in microprocessors need to remove large quantities of heat with “ease”; thus, high TC is desired in such applications. On the other hand, insulation materials in walls and roofs of houses need to “retain” as much heat/cold as possible and hence require very low TC. The SI units of TC are W/m·K.

Figure 1. Heat conduction across a temparature gradient.

However, understanding and measuring heat transfer cannot be achieved through TC alone. For example, Thermal Diffusivity measures the heat transfer rate across a medium. TD determines how fast heat can flow through a cross-section in a unit of time and is measured in mm²/s.

On the other hand, Volumetric Heat Capacity (VHC) refers to the heat required per unit volume of a material to raise the temperature by 1K. The conventional unit of VHC is J/mm³K. TC, TD and VHC are heat transport properties governing heat transfer across a medium. Measuring thermal conductivity and associated thermal properties is becoming increasingly critical in designing optimal systems with efficient thermal management in various applications.

Transient thermal analysis determines temperature variations and associated thermal quantities with time. The variation of temperature distribution over time is of interest in many applications, including cooling electronic packages and quenching of heat-treated metals. Catastrophic failures from thermal strains in structural applications like nozzles, engine blocks, and pressure vessels are evaluated using transient thermal analysis.

For transient measurements, the Transient plane source (TPS) method (ISO 22007-2) provides a fast, versatile, and precise framework to simultaneously measure TC and TD over various materials such as pastes, powders, liquids, thin films, and bulk materials.

The transient plane source method is a non-destructive technique for unlocking a material’s thermal secrets. It works by placing a disc-shaped sensor in intimate contact with the sample. This sensor acts as both a heat source and a thermometer. A short burst of heat is delivered through the sensor, causing the sample’s temperature to rise. The magic lies in how quickly the heat dissipates.

By meticulously recording the temperature response of the sensor as it returns to its initial state, scientists can calculate the material’s thermal conductivity – its inherent ability to conduct heat. This powerful method is remarkably versatile, working across a spectrum of materials, from delicate insulators to potent conductors, and even extends to liquids and fluids.

In the TPS method, a double spiral TPS sensor is either sandwiched (symmetric testing) between two halves of the sample or placed on the sample’s top/bottom (asymmetric testing) with a backing material on the other side. The TPS sensor acts as a “heat source” for delivering the power required to raise the temperature of the sample and as a “resistance thermometer” for recording the time-dependent temperature increase. This approach allows for simultaneous measurement of the power delivered to the sample and thermal transport properties, unlike other methods such as laser flash (ASTM E1461).

The TPS sensor consists of an electrically conducting double spiral-shaped Nickel foil encapsulated between thin sheets of an electrically insulating material. The double spiral shape eliminates the need for longer sample sizes required for methods such as hot wire (ASTM D7896) and hot strip methods (ASTM D5930).

Thermtest offers sensors of varying sizes to accommodate a wide range of sample sizes. Thermtest’s patented TPS Contact Analysis framework employed in the TPS method eliminates the effect of thermal contact resistance between the sensor and the sample surface, offering a unique approach to determining the true bulk properties of the material.

Figure 2. Thermtest’s proprietary Measurement Platform (MP-1) connected to the state-of-the-art TPS Temperature Platform.

TPS measurements are carried out on Thermtest’s proprietary measurement platform (MP-1). The MP-1 is a thermal conductivity instrument compatible with a range of sensors designed to perform robust measurements of thermal transport properties, complete with software capable of data acquisition and transient analysis.

In a TPS Standard Module, the sensor is placed centrally between two identical samples with flat surfaces. This configuration is known as the symmetrical 3D method. The sensor delivers a constant power while simultaneously measuring temperature readings for the selected time interval. Figure 4 illustrates the 3D symmetric configuration using PyroCeram. When comparing the measured and reference values, TC variation is within 2%.

Figure 3. Room temperature set-up of TPS Standard Module sample and sensor assembly with Pyroceram sample.

Rechargeable Li–ion batteries are currently the most viable alternative to fossil fuels for energy needs. Battery cells typically come in different geometries/configurations like cylindrical, prismatic and pouch cells. Numerous cells are stacked together to form battery packs, used as power sources in various applications ranging from power electronics to automobiles.

The heat generated in batteries during charging/discharging can be detrimental to battery life and, if unchecked, can lead to catastrophic failure, known as thermal runaway. The thermal conductivity of Li-ion batteries significantly impacts battery temperature distribution, making TC measurements crucial for designing efficient thermal management systems to improve cell life and thermal runaway outbreaks.

Batteries exhibit directional thermal conductivities along in-plane and out-of-plane directions. This property is known as anisotropy. Thermtest’s custom-designed battery enclosure can measure both in-plane and out-of-plane thermal conductivities using the MP-1 TPS method with the Anisotropic Module.

Figure 4. The experimental setup for battery testing using the Anisotropic Module.

Type 21700 Cylindrical Battery with a diameter of 21 mm and a height of 70 mm was tested for directional TC and TD. The TPS sensor is placed between a known backing insulation and the battery. Measurements are carried out at various operational temperatures (25 °C, 50 °C, 80 °C) using the Temperature Platform. Concerning sensor-sample orientation, the axial/in-plane direction is into the battery core, and the radial/out-of-plane direction is along the length of the battery.

Contact us for customized battery testing.

Thin-films have diverse functional applications in the packaging, electronics, and optical coating industries. Thin-films act as barriers between the substrate and external environment, such as protective layers in the automobile and aerospace industry, sealants in food packaging and semiconductor industries, and surface modifiers (thin-film optics) over glasses.

The thin-film properties heavily influence the temperature distribution of the substrate. For example, lightweight thermal insulation films such as Airloy® X116 are crucial in thermal shielding applications to protect the interior from extreme external conditions.

Measuring the thermal conductivity of thin-films is challenging due to their small size and limited probing depth. Additionally, thin films tend to deform under their weight, making conventional transient and steady-state methods unreliable. Thermtest developed the Transient Thermal Resistance–Thin-Film (TTR-TF) Module to address these issues.

This module provides a fast and convenient method for measuring thin-films up to 1mm thick. TTR-TF module can also be used with adhesives, pastes, and coatings.

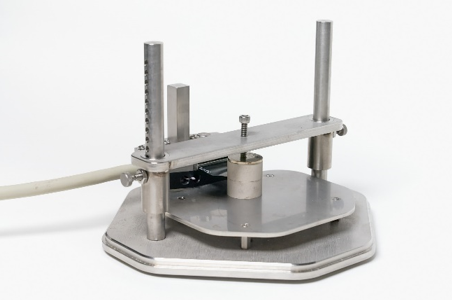

Figure 5. Testing setup for the TTR-TF Module

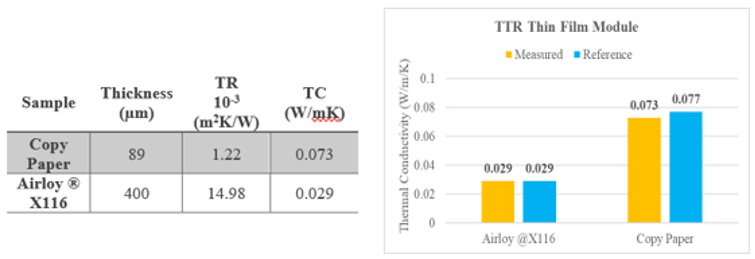

The MP-1 TPS with TTR-TF Module utilizes a 20mm diameter sensor and four pieces of 21mm diameter steel. Two pieces have a length of l1 = 3 mm, and the other l2 = 25 mm. Two pieces of copy paper (89µm thick) and Airloy® X116 (400µm thick) are cut into circles of diameter 21 mm. The thin film samples are placed between l1 and l2.

Testing is carried out with a power input of 1W for a 5-second duration at ambient temperature (23 °C). The TTR-TF module measures the transient thermal resistance (TR) across the film and uses it along with film thickness to calculate TC. The test results presented in Figure 8 show good agreement with reference values (variation within 5%). Contact us for aerogel thin-film property testing using Thermtest measurement platform.

Figure 6. Thermal Conductivity results of copy paper and Airloy tested with TTR thin-film module.

The TPS method is a powerful tool to measure TC and TD of various materials accurately. This article outlines the significance of comprehending and quantifying thermal transport properties using the TPS method. In addition to the bulk materials and thin films, TPS can also be applied to measure a wide variety of powders, pastes, anisotropic materials, liquids, and metal foils.

At Thermtest, we specialize in measuring thermal properties using international standards (ASTM and ISO). We welcome the opportunity to assist you in addressing your thermal management needs. For more information and personalized customer care, contact us here.

Transient plane source element acts simultaneously as a heat source and a temperature sensor.

The Transient Plane Source (TPS) uses a double-spiral disc sensor for versatile thermal property measurements of various materials, while the Modified Transient Plane Source (MTPS) employs a single-sided sensor with known backing insulation for more convenient, calibration-free testing, especially suitable for porous and thin materials.

TPS (Transient Plane Source) equipment is a cutting-edge instrument used to measure the thermal conductivity and other thermal properties of materials with high accuracy. The system utilizes a flat, disc-shaped sensor that functions as both a heat source and a temperature sensor. By applying a controlled heat pulse to the sensor, it detects the transient temperature changes within the sample material. This allows for precise analysis of thermal conductivity, specific heat, and thermal diffusivity. The Thermtest TPS equipment is specifically designed for efficient and reliable thermal analysis, making it an ideal tool for a wide range of industries and research applications.