In the rapidly evolving world of energy storage, lithium-ion (Li-ion) batteries have become indispensable. They power our smartphones, laptops and electric vehicles and are integral to renewable energy systems.

Imagine holding a sleek, portable device brimming with energy. Yet, beneath its polished exterior lies a complex world of heat flow, where understanding thermal conductivity is crucial for maximizing performance and safety. As the demand for these batteries grows, so does the need for effective thermal management. This is where the concept of thermal conductivity, the ability of a material to conduct heat, becomes vital.

Within Li-ion batteries, the phenomenon of anisotropy – where properties differ based on direction – adds a layer of complexity that must be understood to optimize battery function and longevity. Exploring anisotropic thermal conductivity testing reveals the secrets of how heat moves within these batteries, leading to improved performance and longer lifespan.

Heat is a natural byproduct of the energy transfer processes within a Li-ion battery. But just like Goldilocks and her porridge, the temperature must be “just right.” Excessive heat can degrade battery performance, accelerate aging, and even lead to safety hazards. This is where thermal conductivity (TC) comes into play. TC is a material’s inherent ability to conduct heat, and it plays a critical role in ensuring efficient heat dissipation within a battery cell.

Li-ion batteries are the backbone of modern technology, powering everything from our smartphones and laptops to electric vehicles and renewable energy storage systems. These rechargeable powerhouses operate by shuttling lithium ions between the anode and cathode during charging and discharging cycles, creating a reliable and efficient energy source for a wide range of applications.

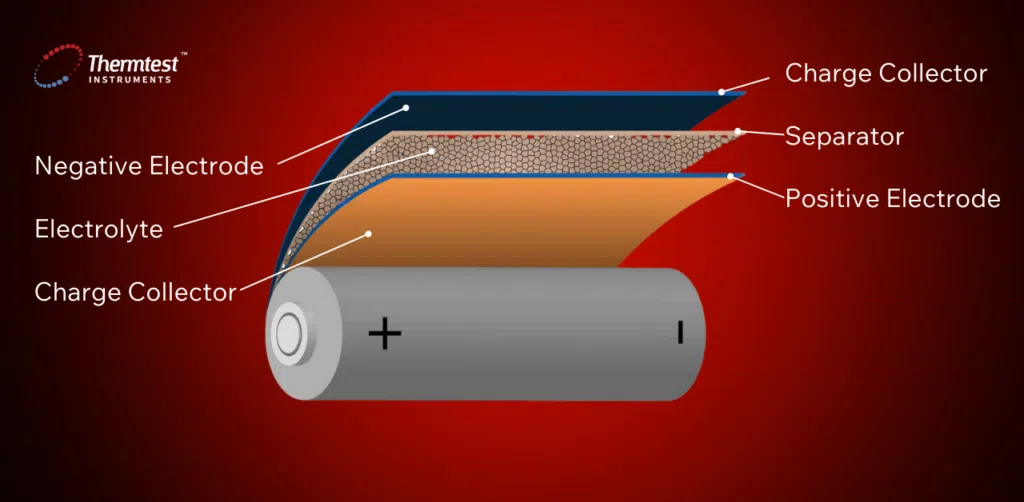

Figure 1. Diagram explaining the internal layers within a battery.

Internally, a Li-ion battery consists of several layers: the anode, cathode, separator, and electrolyte. Each component is crafted from materials with distinct thermal conductivities, influencing how heat is managed within the battery. The precise arrangement and layering of these materials contribute to the battery’s overall performance and its anisotropic thermal behaviour—a property where heat conduction varies based on direction.

As we increasingly rely on Li-ion batteries to drive the shift towards cleaner energy, their role in electric vehicles and renewable energy storage becomes even more critical. Effective thermal management is essential to enhance the performance and extend the lifespan of these batteries. Proper heat dissipation prevents excessive temperatures that can lead to degradation and potential safety hazards, making the study of anisotropic thermal conductivity in Li-ion batteries relevant and vital for advancing energy storage technology.

However, the story of heat flow in Li-ion batteries takes an intriguing twist with the concept of anisotropy. Unlike some materials that conduct heat uniformly in all directions, Li-ion batteries exhibit anisotropic thermal behaviour—this means their thermal conductivity varies depending on the direction of heat flow. For example, heat might flow more readily within the layers of the electrode materials (in-plane) than across them (out-of-plane).

Anisotropy in materials means that their properties vary depending on the direction in which they are measured. In the context of Li-ion batteries, anisotropy is particularly relevant due to the varied thermal conductivities within the battery’s structure. This characteristic influences how heat is managed across different parts of the battery, affecting overall performance and safety.

Li-ion batteries come in several shapes, each with its own thermal characteristics:

Internally, Li-ion batteries consist of layered materials and interfaces that exhibit anisotropic thermal properties. The alignment of these layers and the varying conductivities in different directions require sophisticated testing to measure and manage heat transfer within the battery accurately. Understanding and optimizing these anisotropic characteristics is essential for enhancing battery performance and ensuring safety under various operational conditions.

Accounting for anisotropy is essential for accurate thermal modelling and designing efficient cooling systems for Li-ion batteries. Traditional thermal conductivity measurements, which assume isotropic behaviour (uniform heat flow), can provide misleading results. This is where anisotropic thermal conductivity testing steps in.

Researchers can measure the thermal conductivity of Li-ion batteries in both in-plane and out-of-plane directions by employing specialized techniques, such as the Transient Plane Source (TPS) method with an Anisotropic Module.

This comprehensive data allows engineers to:

The directional thermal conductivity and thermal diffusivity of Li-ion pouch batteries was determined using Thermtest’s MP-1 TPS Battery Package.

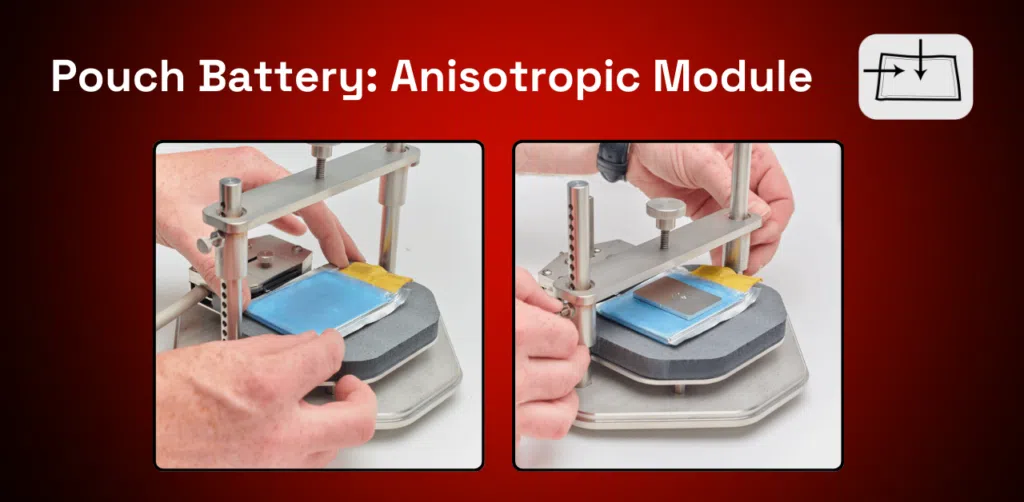

Figure 2. The MP-1 with the TPS battery package for testing the thermal conductivity of batteries.

For anisotropic tests, the material’s specific heat must be known, which can easily be determined using the Specific Heat Module. The battery was set up in an asymmetric configuration (single-sided), with the sensor sandwiched between the pouch battery and an insulated backing material with known thermal properties.

Figure 3. Set up for testing pouch cell batteries.

| Sample Type | Temperature (°C) | Axial Thermal Conductivity (W/m•K) | Axial Thermal Diffusivity (mm²/sec) | Radial Thermal Conductivity (W/m•K) | Radial Thermal Diffusivity (mm²/sec) |

| Pouch cells | 25 | 0.58 | 0.20 | 45.10 | 16.50 |

| 50 | 0.66 | 0.25 | 37.21 | 16.70 | |

| 80 | 0.67 | 0.30 | 38.20 | 18.2 |

Table 1. Resulting directional thermal conductivity and thermal diffusivity of an anisotropic pouch cell battery sample.

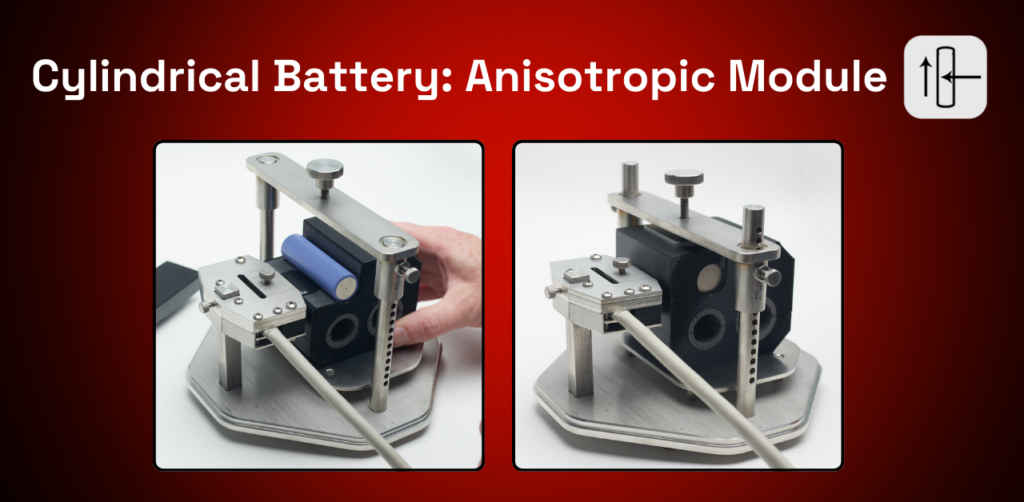

The directional thermal conductivity and thermal diffusivity of cylinder batteries were also determined using Thermtest’s MP-1 TPS Battery Package. The cylinder battery was set up in a specialized cell in an asymmetric configuration, with the sensor sandwiched between the pouch battery and the cell’s insulated backing material.

Figure 4. Set up to test cylindrical batteries

Due to this sample sensor orientation, the axial thermal properties are measured in the center of the battery, and the radial thermal properties are measured along the length or height of the cylinder battery.

| Sample Type | Temperature (°C) | Axial Thermal Conductivity (W/m•K) | Axial Thermal Diffusivity (mm²/sec) | Radial Thermal Conductivity (W/m•K) | Radial Thermal Diffusivity (mm²/sec) |

| Cylinder | 25 | 0.29 | 0.13 | 32.2 | 13.7 |

| 50 | 0.25 | 0.10 | 35.4 | 14.2 | |

| 80 | 0.23 | 0.08 | 41.1 | 15.2 |

Table 2. Resulting directional thermal conductivity and thermal diffusivity of an anisotropic cylinder battery sample.

The MP-1 with TPS allows a proprietary curve correction for the error that exists when applying a TPS sensor to a curve. This correction is described as a convolution of two functions, f(x) and g(x), each of which corresponds to the effects of a single direction. By changing the scale of each function independent of the other, the data can be fit to a calculated curve. The result has proven to be in agreement with the 1D and radial results.

The MP-1 with TPS Battery Package accurately measures the thermophysical properties of pouch and cylinder-type batteries. Customers value these reliable results, which greatly decreases uncertainty in their thermal simulations.

Explore more about the other applications of batteries.