June 4, 2024

Understanding the thermal properties of materials is crucial in various industries, particularly those involving heat transfer and temperature control. Polymers, with their diverse properties and applications, are no exception. The Transient Plane Source (TPS) method offers a reliable and efficient way to evaluate the thermal properties of polymers, providing valuable insights for material selection, design, and performance optimization.

In this article, we’ll explore the TPS Polymer Series, a dedicated set of tools and procedures specifically designed for thermal property analysis of polymers. We’ll also explore this method’s key features and benefits, application process, and advantages compared to other thermal property measurement techniques.

The TPS Polymer Series is a comprehensive suite designed to measure polymers’ thermal properties accurately. The Thermtest Measurement Platform Advanced (MP-1) measures absolute bulk and directional thermal conductivity and thermal diffusivity for solids, pastes, and powders without calibration or contact agents. It utilizes the well-established Transient Plane Source (TPS) method, which involves:

By analyzing the temperature response, the TPS system calculates the following fundamental thermal properties of the polymer sample:

The TPS Polymer Series also includes the TPS single-sided sensor, specifically designed for situations where only one piece of sample material is available or when testing large, hard-to-handle samples. This sensor configuration allows for thermal property measurements without requiring a second half of the sample, making it ideal for:

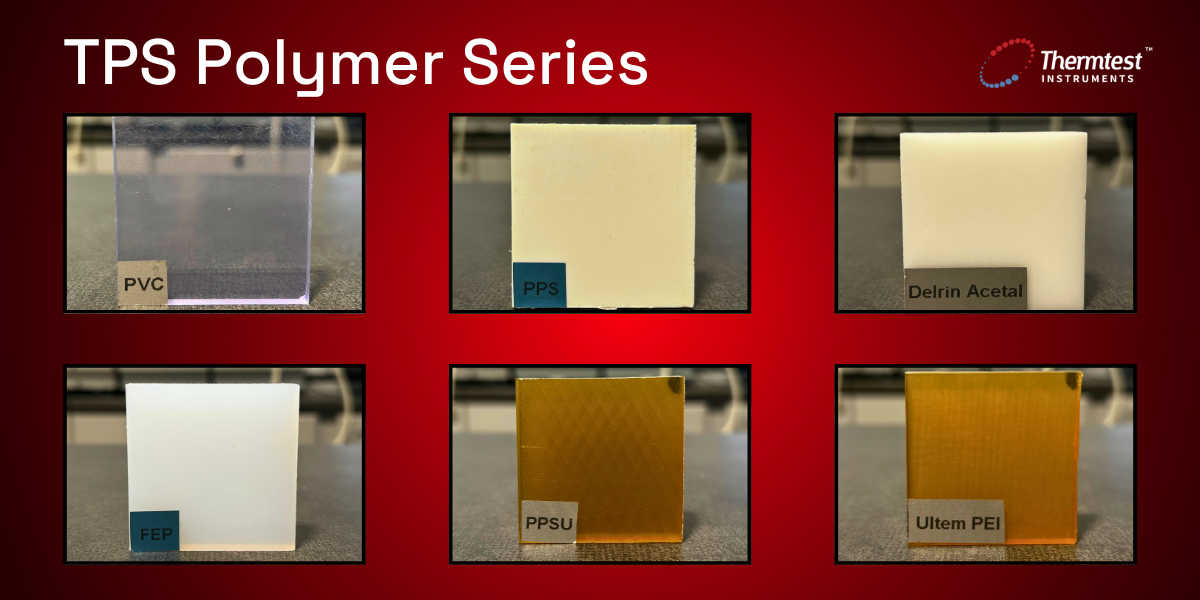

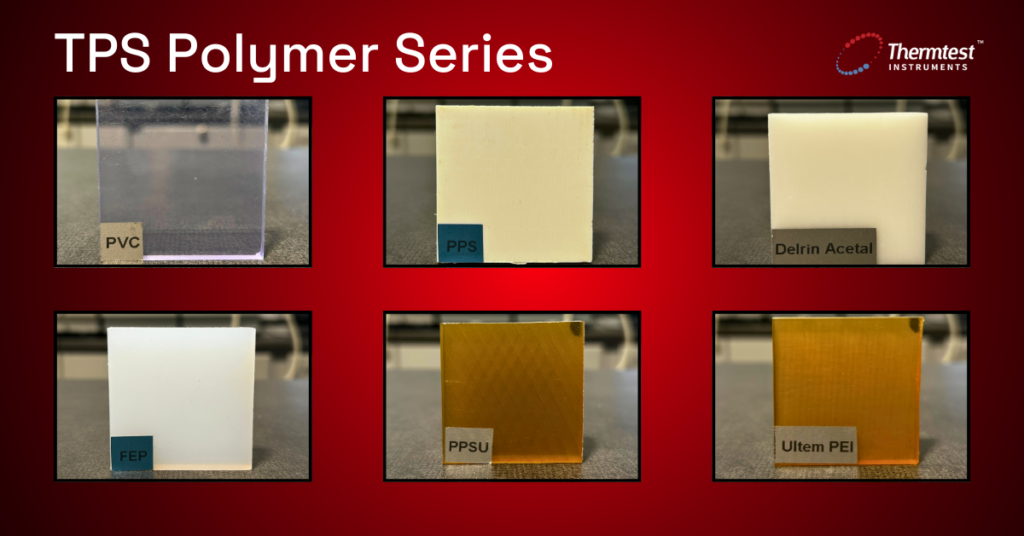

The TPS Polymer Series, including the single-sided sensor, has been successfully used to evaluate the thermal properties of various polymers, including:

The data obtained from these tests provides valuable insights into the thermal behaviour of these polymers, which can be utilized in various applications:

Furthermore, the data obtained from TPS testing can be used to create thermal models that predict the behaviour of these materials under different thermal conditions. This information is crucial for optimizing product designs, ensuring efficient heat management, and predicting the performance of polymer components in various applications.

The TPS Polymer Series offers several advantages over other thermal property measurement methods:

The TPS Polymer Series involves a straightforward process:

This process can be repeated for multiple samples of the same polymer or different polymers, allowing for comprehensive comparisons and material selection based on specific thermal property requirements.

Figure 3. The polymers pictured above can be effectively evaluated using the TPS Polymer Series.

Here are some examples of polymers that can be effectively evaluated using the TPS Polymer Series:

The TPS Polymer Series offers several advantages for polymer evaluation:

The TPS Polymer Series generates accurate and reliable data on the thermal properties of polymers. These results find applications in various industries, including:

The results obtained through the TPS Polymer Series can be compared with established reference values or data from other measurement methods to validate accuracy and ensure consistency with industry standards.

| Polymer Name | Bulk Thermal Conductivity (W/m•K) |

Bulk Thermal Diffusivity (mm2/s) |

General/ High Temperature |

Isotropic/ Anisotropic |

Reference Thermal Conductivity (W/m•K) |

| Polyetherimide (Ultem) | 0.22377 | 0.17325 | High Temperature | Isotropic | 0.221 |

| Polyphenyl sulfone (PPSU) | 0.3097 | 0.2043 | High Temperature | Isotropic | 0.302 |

| Polyphenylene sulfide (PPS) | 0.2989 | 0.1928 | High Temperature | Isotropic | 0.303 |

| Polyvinyl chloride (PVC) | 0.18716 | 0.14783 | General | Isotropic | 0.164 |

| Fluorinated ethylene propylene (FEP) | 0.21953 | 0.13689 | High Temperature | Isotropic | 0.20 ± 0.045 |

Table 1. Summary table of polymers measured with corresponding bulk thermal property values and reference thermal conductivity values.

Polyamide-imide (Torlon) was measured using the TPS anisotropic module after it was discovered that the measured bulk thermal conductivity value was quite high compared to the reference. An important consideration when comparing bulk to through-thickness values, like measured values by ASTM C177, is the possibility that the materials may be anisotropic. It was then decided that the Torlon sample should be investigated for anisotropy.

| Polymer Name |

Through-Thickness Thermal Conductivity (W/m•K) |

Through-Thickness Diffusivity (mm2/s) |

General/ High Temperature |

Isotropic/ Anisotropic |

Reference Thermal Conductivity (W/m•K) |

| Polyamide-imide (Torlon) | 0.55045 | 0.45871 | High Temperature | Anisotropic | 0.546 |

Table 2. The Summary table for Torlon has corresponding through-thickness thermal properties values and reference thermal conductivity values.

The experimental results showed the accuracy of the transient plane source (TPS) method for testing low-conductivity materials such as plastic polymers. It is also a valid indication of the high precision and accuracy of the transent plane source single-sided sensor when double-sided testing is not favourable.

The Transient Plane Source Polymer Series offers a valuable tool for accurately and efficiently evaluating the thermal properties of diverse polymers. The TPS Polymer Series empowers researchers, engineers, and manufacturers to make informed material selection decisions, optimize processes, and ensure consistent thermal performance in various applications by providing comprehensive data on thermal conductivity, diffusivity, and specific heat capacity.

Understanding and characterizing the thermal properties of polymers is crucial for their successful implementation in a wide range of industries. The TPS Polymer Series provides a reliable and efficient solution, paving the way for optimized material selection and improved product performance.