Test Times and TPS Sensors

The selection of sensor and control of test time during transient is critical to ensure representative results.

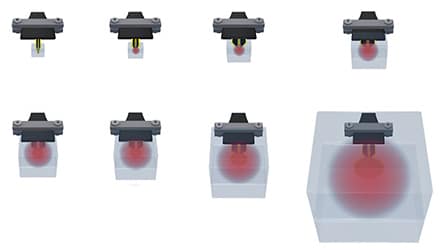

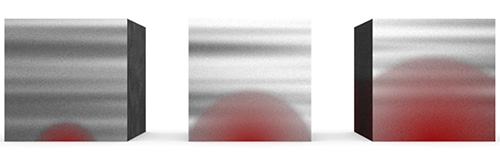

Time. Transient theory states that heat from sensor must stay within the body of the sample, but also penetrate deep enough to be considered “true”. This is especially important for heterogenous materials. The nature being for insulative materials, test times tend to be longer while shorter for more conductive materials.

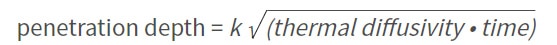

Based on the dimensions of your sample and its measured or known thermal diffusivity, a time-based penetration depth can be estimated. The below penetration depth calculator can be used to determine penetration depths:

Penetration Depth Calculation

Where k = temperatures recording sensitivity constant

Penetration depth increase with increase of test time.

Thermtest has developed a convenient penetration depth calculator in our thermal resource to predict the required time for your dimension of sample. Try it out: https://thermtest.com/thermal-resources/heat-penetration-calculator

Test time range of the MP-1 with TPS is 0.25 to 1280 seconds.

TPS Sensor. Assumptions of transient methods are such that materials are homogenous. For homogenous materials, selection of sensor diameter is less critical. Though, it is still best practice for sample to be at least twice the diameter of the sensor and thickness equal or greater than the radius of selected sensor. For heterogenous materials, this is extremely important to select sensor that maximize contact and penetration depth with the sample and available dimensions to ensure true thermal conductivity is measured.

Sensor diameters available on the MP-1 are 1 to 60 mm.