June 19, 2019

Incorporating additional materials into concrete that improve its thermal properties.

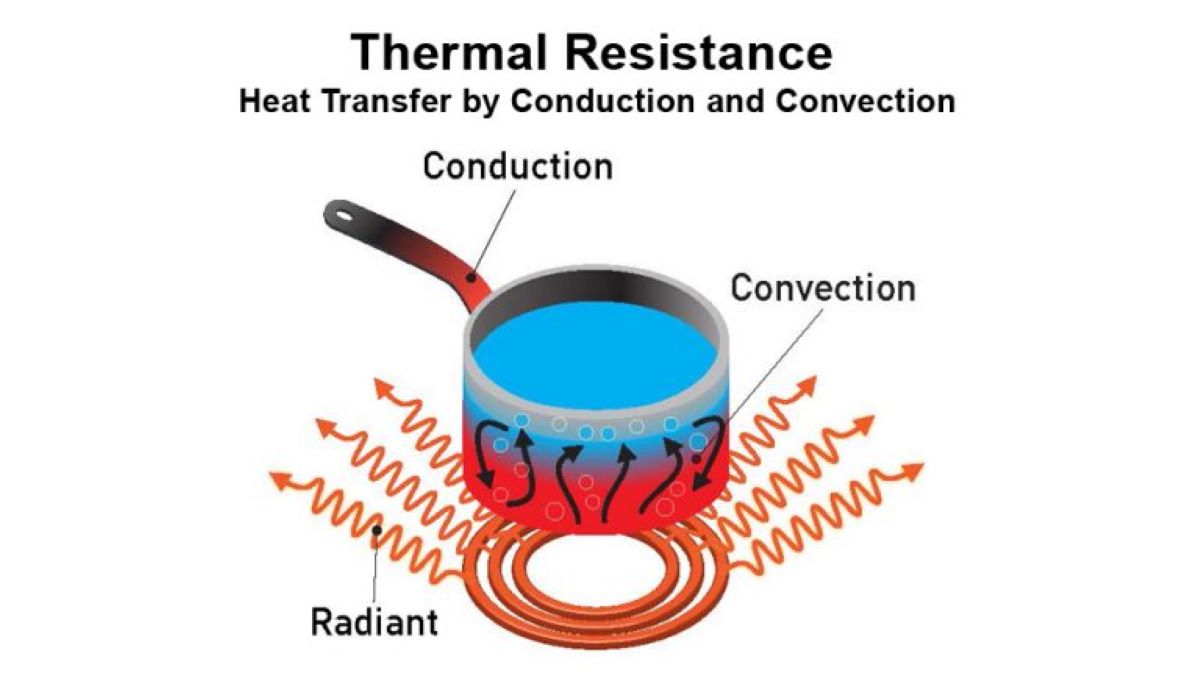

Thermal conductivity is an extremely important property of many common metals and materials that allows their heating capabilities to be used in an effective and efficient way. Materials with a high thermal conductivity allow heat and electricity to easily pass through them and enable effective heat transfer.

A great example of a thermally conductive material used in everyday living is cast iron pans. The metal that these pans are made of allows for heat to be easily transferred from a hot stove surface to the pan where that heat can be retained and used to cook your eggs in the morning. Another important component of a cast iron pan is its handle. Most pot and pan handles are made from wood or plastic due to their insulating properties. These materials are classified as thermally resistive materials due to the slow rate at which heat passes through them.

Thermal resistance is considered the inverse of thermal conductivity. A materials thermal resistance can be measured by that materials ability to resist the flow of heat through it. Many materials with a high thermal resistance are known as insulators and are commonly used to keep or trap an area of hot or cold. For example, a Styrofoam cooler is used to keep drinks cold that are stored inside of it because it is slow to transfer the heat from its surroundings into the confined chilled area inside the cooler. Thermal resistance is a key component in the engineering of thousands of products that are used every day around the globe.

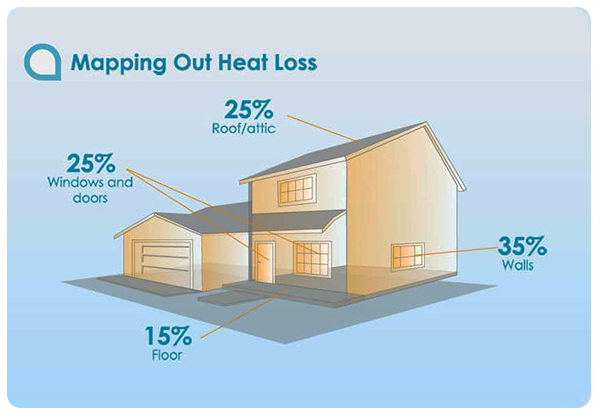

One of the most useful and widespread thermally resistive material is the concrete that is used during the construction of buildings and homes. A building can be easily compared to a Styrofoam cooler. The foundation and walls of a building are trapping the flow of the hot or cold air from the outdoors and maintaining a uniform temperature inside. Builders when constructing a home or building take into consideration the thermal resistance properties of the materials that they are using to create the foundation. Building with materials that have a high thermal resistance can dramatically increase the energy savings and in turn the economic savings for the future owner of that home or building. This is the main factor that is contributing to the spike in research to discover the best combination of insulating materials that can be used during the construction of homes and buildings.

Figure 1: Mapping out heat loss on a standard house design

Recently, a substantial amount of research is being dedicated to discovering a material that can be incorporated into a cement mix that will increase the thermal resistance properties of the cement. Cement is composed of a mixture of sand, gravel, broken stone and water. Cement rarely has a uniform composition and particle sizes vary throughout the mixture. Due to cement’s lack of a “perfect recipe”, other substances can be easily incorporated into the mixture. A recent study conducted by Sikora P. et al researches the pros and cons of incorporating magnetite powder into a cement mixture to improve its thermal resistance and strength.

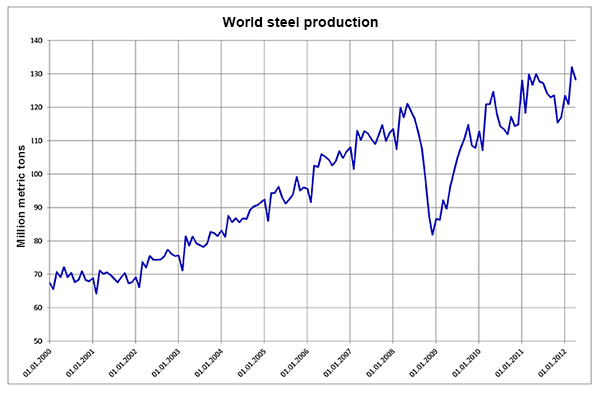

Magnetite powder (MP) and other iron composites are often formed as waste during steel production. The 20th century industrial boom that followed the industrial revolution of the 19th century has led to an overabundance of waste from exploiting multiple types of resources. Recent advances in recycling and waste management are starting to research new ways to harness additional products and energy from the waste that is produced during the initial production of a material. Combining MP into cement mixture is one example of integrating production waste into a common material to help improve some of its physical and chemical properties.

Figure 2: line graph displaying world steel production

from 01/01/2000 – 01/01/2012 in millions of metric tons

When magnetite powder (MP) is incorporated into a cement mixture, less water is required for the particles to bond and harden. This improvement alone would save construction companies energy and minimalize freshwater use. The results from the study also showed that replacing 20% of the sand in the mixture with MP increased the flexibility and strength of the cement.

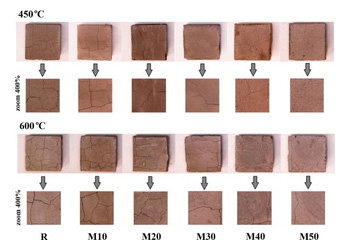

Figure 3: Image of magnetite powder

To test the change in thermal resistance of the cement with the addition of magnetite powder, the researchers analyzed the appearance and thermal conductivity of the cement after being exposed to a range of temperatures. Ten different cement tiles were used with the MP volume % ranging from 5 – 50%. Each sample was cured for 28 days before being exposed to the heated conditions. The thermal and physical properties of each cement tile were measured at elevated temperatures of 200°C, 300°C, 450°C and 600°C. The samples were heated at a constant rate of 1°C per minute until the desired temperature was achieved. Each tile was then continuously heated at the max temperature for 1 hour then slowly cooled at a rate of 1°C per minute.

The results from the experiment displayed a higher thermal conductivity in the plates of cement that had a higher MP vol %. The higher conductivity was likely due to the increased amounts of metal included in the cement. Metal is one of the best thermal conductors so even a trace amount would likely decrease the thermal resistance of the cement.

The addition of MP did increase the strength of the cement when exposed to higher temperatures. These conclusions led researchers to an undecided conclusion if it is beneficial to include MP in cement mixtures. Further research could lead to finding the desired vol % of MP that can be added to cement that will increase strength and energy efficiency but keep the thermal resistance of cement high as well.

Figure 4: Cement plates after being exposed to heated conditions.

The concept of adding additional substances to cement has opened doors for other research projects to test the benefits of including a variety of different materials into a cement mixture. If insulating materials such as plastics and foams are incorporated into cement, they ideally could increase the thermal resistance of the cement and minimalize heat loss through the foundation and walls of homes and buildings. Using recycled plastics in the production of a widely produced material like cement would solve many municipalities waste recycling issues. The only con with including plastic is it might not withstand extreme temperatures without melting or breaking down. Another issue would be the high amount of energy that would be required to break down the plastic products to sizes small enough to be incorporated into a uniform cement mixture.

Progress is continuing to be made towards creating more environmentally and energy friendly products and materials that can replace and be incorporated into the currently wasteful production systems. The thermal potential of substances is going to be one of the most important properties that the researcher will use to achieve the most energy efficient and cost-effective solution to create more sustainable materials and environmentally safer production systems.

Thermal Resistance in Series Calculator

Heat Conduction Calculator

Sikora, P., Abd Elrahman, M., Horszczaruk, E., Brzozowski, P., & Stephan, D. (2019). Incorporation of magnetite powder as a cement additive for improving thermal resistance and gamma-ray shielding properties of cement-based composites. Construction and Building Materials, 204, 113-121. doi:10.1016/j.conbuildmat.2019.01.161

Image Sources:

https://www-sciencedirect-com.proxy.hil.unb.ca/science/article/pii/S095006181930193X

https://www.greenhomegnome.com/energy-loss-homes-insulation/

https://commons.wikimedia.org/wiki/File:World_steel_production.png

https://commons.wikimedia.org/wiki/File:Iron_powder_on_magnetic_stirrer_04_ies.webm

Main Image: https://commons.wikimedia.org/wiki/File:Heat_Radiation_Transparent_2_(26046216082).jpg

Author: Kallista Wilson, Junior Technical Writer at Thermtest