August 26, 2024

The emergence of plastics in the development and acceptance of E-vehicles is pivotal. Learn why these materials are more than just components—they’re the foundation of the automotive industry.

Automotive batteries are silently powering the electrical systems that we rely on every day. Within these powerhouses lies a complex interplay of components, in which plastics play a pivotal role. Not only do plastics protect the delicate chemistry of the battery, but they also contribute to the overall performance and durability of the power unit. In this article, we delve into the world of battery plastics, highlighting the most common types used and their significance in the realm of automotive power storage.

From providing resistance to corrosive materials to ensuring the structural integrity of batteries under highly vibrational conditions, plastics have become essential. Their ability to be molded into precise shapes and configurations allows for the optimization of space and the integration of batteries into the ever-changing designs of modern vehicles. Join us as we explore the top 10 battery plastics that are essential to automotive battery technology and the reasons why they are chosen for this critical application.

The selection of plastics in automotive batteries is based on a balance of properties such as chemical resistance, thermal stability, mechanical strength, and cost-effectiveness.

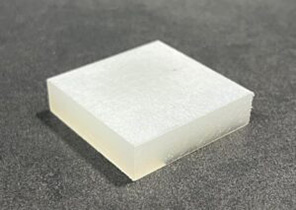

Figure 1: Polypropylene sample

Applications: Casings, containers, separators.

Advantages: Chemical resistance, durability, lightweight, economical.

Polyethylene is primarily used in the form of separators. These separators are vital in preventing short circuits by keeping the positive and negative plates within the battery apart while allowing the necessary ion exchange. PE is selected for this role due to its excellent electrical insulating properties and its flexibility, which are essential for maintaining the battery’s integrity over time.

Applications: Separators within the battery.

Advantages: Superior insulation, flexibility, chemical resistance.

Figure 2: Polyvinyl Chloride (PVC)

Applications: Insulation, protective housings, cable covers.

Advantages: High resistance to chemicals, flame retardant, durable.

Acrylonitrile butadiene styrene, known for its strength and impact resistance, is frequently utilized in the structural components of automotive batteries. ABS’s ability to withstand physical stress makes it an excellent material for battery housings, ensuring the battery remains intact and operational even in demanding conditions such as vibrations and shocks present in engines.

Applications: Battery housings, structural elements.

Advantages: Impact resistance, mechanical strength, durability.

Figure 3: Polycarbonate Samples

Applications: Transparent covers, high-performance components.

Advantages: Impact resistance, heat tolerance, transparency.

Polyethylene Terephthalate is valued in automotive batteries for its mechanical strength and resistance to water and chemicals. Its durability makes it ideal for use in battery containers and support structures, where it can withstand the mechanical stresses of the automotive environment. Additionally, PET’s recyclability aligns with the growing trend toward sustainable practices in the automotive industry.

Applications: Containers, support structures.

Advantages: High mechanical strength, chemical resistance, environmentally friendly.

Polyamide, or nylon, is another commonly used plastic in automotive batteries due to its exceptional mechanical properties, including high strength and resistance to wear. It is often used in components that must endure mechanical stress, such as connectors and clamps. PA’s ability to resist oils and other automotive fluids further enhances its suitability for these applications.

Applications: Terminal connectors, clamps.

Advantages: Strength, wear resistance, fluid resistance.

Polystyrene is often employed in automotive batteries for components that benefit from its rigidity and ease of molding. PS is used in non-structural parts such as spacers within the battery, where its lightweight and cost-effectiveness make it an attractive choice for mass production.

Applications: Spacers, internal battery components.

Advantages: Lightweight, rigid, economical.

Polybutylene Terephthalate is frequently chosen for its electrical insulation properties and resistance to heat and chemicals. In automotive batteries, it is used in components like connectors, where maintaining electrical integrity is paramount. PBT’s durability ensures that these components continue to perform effectively under various environmental stresses.

Applications: Connectors, insulators.

Advantages: Electrical insulation, heat resistance, chemical durability.

EPDM is a synthetic rubber widely used in automotive batteries for sealing and gasketing applications. Its excellent resistance to heat, weathering, and ozone oxidation makes it ideal for components that must maintain a tight seal across varying environmental conditions. The flexibility of EPDM over a wide temperature range ensures that it remains effective in diverse climates.

Applications: Seals, gaskets, weatherproofing.

Advantages: Heat and weather resistance, flexibility (William D. Callister Jr., 2018)

An automotive battery is comprised of several components, each playing a crucial role in its operation:

Thermal analysis encompasses a range of techniques that provide insights into materials by observing how their structures and properties change with temperature variations. Polymers are sensitive to these changes due to their large, extended chain molecules, which allow for a wide variety of structural arrangements. The complexity and non-uniformity of individual polymer units contribute to their unique behavior.

Additionally, polymers exist in a dynamic state, balancing between an elastic solid and a viscous fluid, making considerations of time or frequency just as crucial as temperature. This is why thermal analysis is invaluable for researchers and manufacturers in understanding the critical aspects of these complex structures. (Sepe, 1997)

Thermtest provides apex instruments combined with proprietary technologies to intelligently measure thermal conductivity, thermal diffusivity, specific heat, and thermal effusivity of complex plastics and polymers using the transient and steady-state methods. To see our apex instruments, like the MP-1 TPS with battery package and MP-V.

| Type of Plastic | Application | Thermtest Instruments |

| Polypropylene (PP) | Battery casings | MP series / GHFM-01 |

| Polyethylene (PE) | Separators | MP series / GHFM-01 |

| Polyvinyl Chloride (PVC) | Insulation | MP series / GHFM-01 |

| Polycarbonate (PC) | Transparent covers | MP series / GHFM-01 |

| Acrylonitrile Butadiene Styrene (ABS) | Battery casings | MP-1 battery package |

Table 1: Common Plastics Used in Automotive Batteries and Suitable Testing Methods

The majority of polymers fall under the category of plastics, which are highly valued in the automotive industry due to their exceptional properties. In recent years, the use of battery plastics in vehicles has increased multifold, particularly with the growing popularity of Electric Vehicles (EVs).

Plastics have become increasingly vital to the auto industry, playing key roles in automotive batteries due to their chemical resistance, durability, and thermal stability. Each type of plastic contributes significantly to battery performance, whether it’s the polypropylene (PP) casing that shields internal components or the polyethylene (PE) separator that prevents short circuits.

As the automotive industry continues to advance, the selection of high-performance plastics will remain critical in developing safer and more efficient batteries. (More Plastics Used in Automobiles, Improving Fuel Efficiency, Safety and Performance , 2023)

In the pursuit of more efficient and sustainable automotive batteries, the importance of plastics cannot be overstated. These materials not only enhance battery performance and safety but also support the development of next-generation energy storage solutions.

As technology progresses, choosing the right plastics for automotive batteries will become even more crucial. Selecting the appropriate thermal analysis tools is essential to ensure that these materials are durable and capable of withstanding high temperatures.

What essential parts are needed to make a battery?

An automotive battery consists of several key components: electrode, electrolyte (battery acid), positive and negative plates, separators, battery casing, connectors, terminals, and vent caps.

What type of plastic is used in car batteries?

Common plastics used in automotive batteries include Polypropylene (PP), Polyethylene (PE), Polyvinyl Chloride (PVC), and Acrylonitrile Butadiene Styrene (ABS), among others.

What is the best material for battery casing?

Polypropylene (PP) is often considered the best material for battery casing due to its chemical resistance, durability, and lightweight nature.

What is the casing material of a battery cell?

The casing of a battery cell is typically made from Polypropylene (PP) or Acrylonitrile Butadiene Styrene (ABS) due to their robustness and resistance to harsh environmental conditions

Car Batteries Guide: Components, Types, and Functions. (2022, December 23). Retrieved from autoprotoway.com: https://autoprotoway.com/car-batteries/

More Plastics Used in Automobiles, Improving Fuel Efficiency, Safety and Performance . (2023, March 06). Retrieved from American Chemistry Council: https://www.americanchemistry.com/chemistry-in-america/news-trends/press-release/2023/report-more-plastics-used-in-automobiles-improving-fuel-efficiency-safety-and-performance

Sepe, M. (1997). Thermal Analysis of Polymers. Retrieved from Rapra review Reports: https://books.google.ca/books

William D. Callister Jr., D. G. (2018). Material Science and Engineering. John Willey & Sons Inc.