December 9, 2024

Learn how thermal conductivity impacts the performance and lifespan of automotive battery components.

An automotive battery acts as the powerhouse for vehicles by storing and supplying electrical energy to various car systems. This essential function is complex in its application, and the battery’s ability to perform efficiently and safely relies on proper material design and configuration.

As electric vehicles become more popular, understanding the impact thermal conductivity has on automotive batteries and their components becomes increasingly important. Today, we will explore a few battery components and examine how thermal conductivity affects their performance.

The automotive battery is a key component in vehicles because it supplies power to their systems. While traditional internal combustion engine (ICE) vehicles depend on batteries primarily for starting engines and powering accessories, electric vehicles (EVs) use advanced battery systems to power the entire vehicle. Batteries are the primary energy source in electric vehicles, enabling them to operate without gasoline or diesel.

When it comes to selecting the right battery for an EV, lithium-ion cells are the most commonly used due to their high energy density, efficiency, and ability to be recharged quickly. Without a dependable battery, the vehicle cannot function properly, which makes battery design and performance crucial for a positive driving experience.

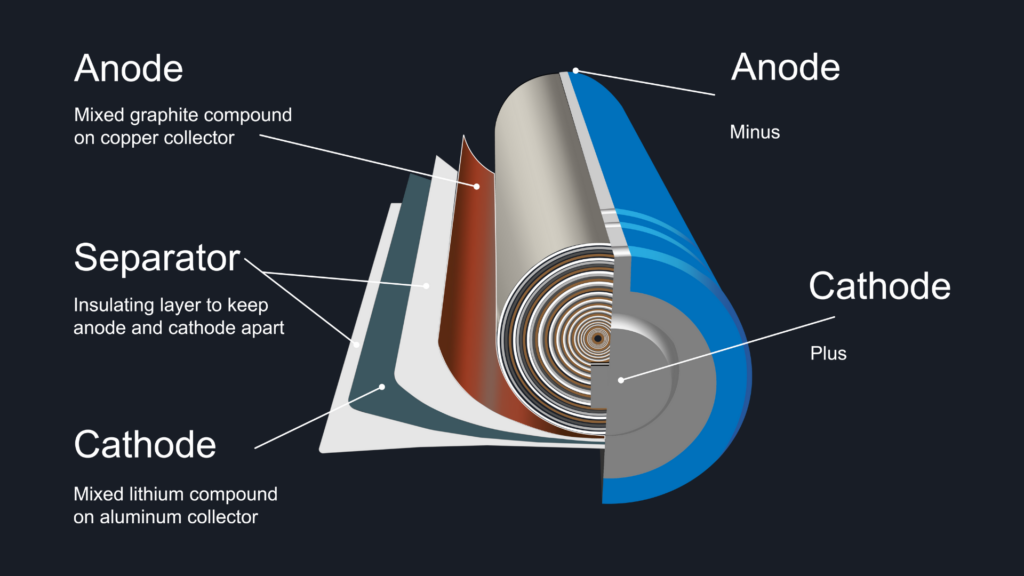

Automotive batteries are comprised of many components, each of which has a unique role in ensuring the battery’s performance and efficiency. Understanding the heat transfer properties of these components impacts how they are designed.

Figure 1: Core components of a battery

Thermal conductivity measures a material’s ability to conduct heat. In the context of automotive batteries, it plays a critical role in ensuring the battery and its components operate efficiently and safely. Since heat is generated by the electrochemical reactions within the battery, this heat must be controlled effectively to prevent thermal runaway and the degradation of the components.

Thermal runaway occurs when the battery temperature gets too high. This can damage the battery or even start a fire. Thus, engineers implement materials into battery design that manage heat effectively and keep the temperature under control.

Evidently, thermal conductivity and battery performance have a direct relationship. Materials that manage heat effectively help the battery stay in optimal operating temperatures, increasing its longevity and safety.

Some materials are used more often in automotive batteries because they have high thermal conductivity. Essentially, these materials are chosen because they improve heat management and ensure the battery operates within acceptable temperature limits.

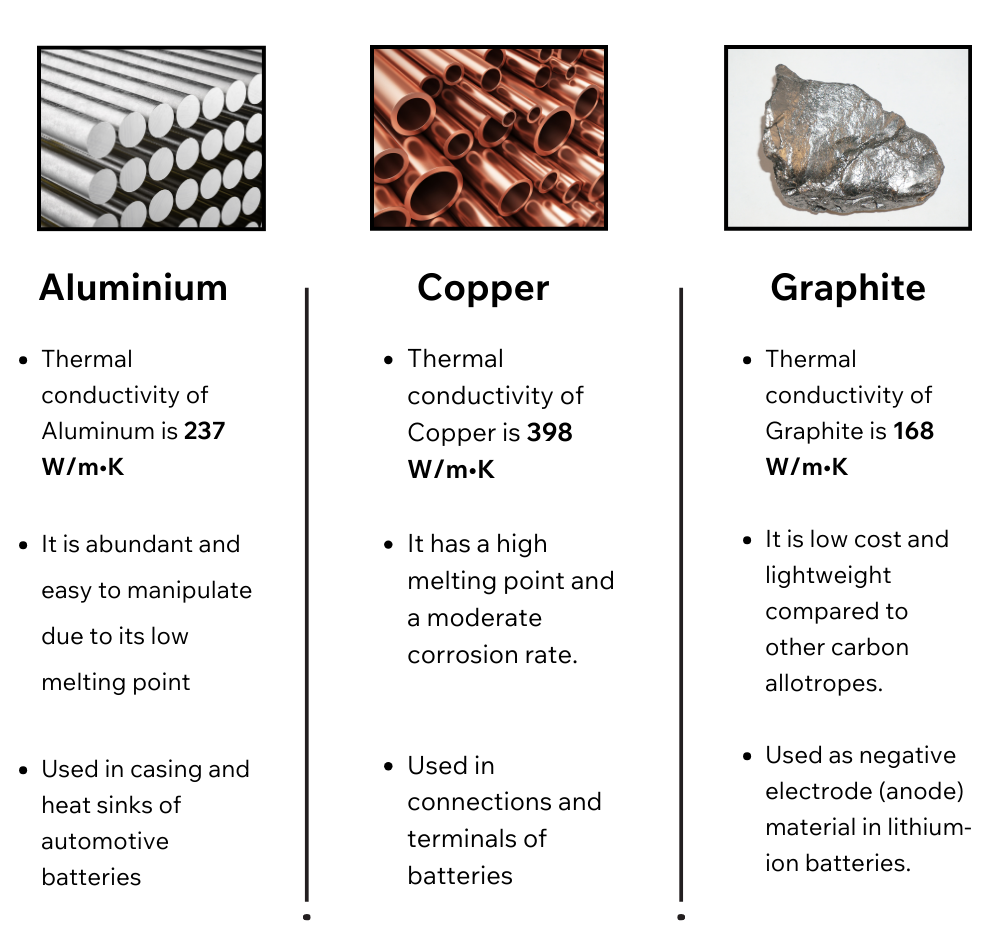

Using materials like aluminum, copper, and graphite can improve the efficiency and safety of the battery system, helping to reduce the risks associated with thermal management failures.

Figure 2: Comparing thermal conductivity between Aluminum, Copper and Graphite

The success of managing heat in automotive batteries relies on precisely measuring the heat-conducting ability of the materials used to build them. Measuring this ability is crucial for making sure the battery works properly in different situations.

Transient Plane Source: The transient plane source method is a non-destructive technique for unlocking a material’s thermal secrets. It works by placing a disc-shaped sensor in intimate contact with the sample. This sensor acts as both a heat source and a thermometer. A short burst of heat is delivered through the sensor, causing the sample’s temperature to rise. The magic lies in how quickly the heat dissipates. By meticulously recording the temperature response of the sensor as it returns to its initial state, scientists can calculate the material’s thermal conductivity – its inherent ability to conduct heat. Check out Thermtest’s MP-1 with TPS Battery Package.

Laser Flash Analysis (LFA): This is a popular way to measure thermal conductivity. It works by using a laser to send a quick burst of light to the surface of a material and then checking how the heat moves. This method gives accurate results and is often used when creating new materials for batteries.

Steady State Methods: In this, heat is added to one side of the material and the temperature change across the material is recorded. These techniques help evaluate materials under actual working conditions. Thermtest’s Guarded Heat flow meter (GHFM-01) is designed to test the thermal resistance and thermal conductivity of both homogeneous and heterogeneous materials.

Testing and standardization of automotive components are important in ensuring that the materials used meet the safety guidelines and performance standards. Therefore, consistency in thermal conductivity ensures that the battery can handle heat transfer efficiently, improving the longevity of the batteries and reducing the risk of failure.

The role of thermal conductivity in automotive battery systems is of utmost importance for understanding the design, performance, and safety of vehicles. By using materials such as aluminum, copper and graphite, manufacturers can ensure efficient heat dissipation, which not only prevents dangerous conditions like thermal runaway but also directly impacts the battery’s lifespan and overall efficiency.

With increasing demand for electric vehicles, maintaining and optimizing battery health through proper thermal management is becoming essential for the industry to keep growing continuously. By choosing high-performance materials and accurate testing methods, we can ensure that EV batteries are safer, more efficient as well as longer lasting.

The key parts of an automotive battery consist of cells that store and convert chemical energy into electrical power, along with electrodes (anode and cathode) where electrochemical reactions take place to generate energy. The electrolyte facilitates ion movement between the electrodes, while the separator keeps them apart to avoid short-circuiting. Finally, the Battery Management System (BMS) oversees and manages the battery’s performance, ensuring both safety and efficiency. All these components work together to guarantee the battery operates reliably in powering the vehicle.

Thermal conductivity plays a vital role in automotive batteries by managing the heat produced during their operation, which is key to ensuring both safety and efficiency. Efficient heat transfer helps prevent overheating, a condition that can result in thermal runaway, shorten battery life, or even create safety risks like fires. To maintain stable temperatures, materials with high thermal conductivity such as aluminum, copper, and graphite are utilized in battery components, enhancing durability, performance, and safety. Effective thermal management is crucial for maximizing battery efficiency and prolonging its lifespan in electric vehicles.

Thermal management plays a crucial role in the performance of batteries in electric vehicles by controlling the temperature of the battery cells during use. Proper thermal management helps prevent overheating, which can damage battery components, lower efficiency, and shorten the battery’s lifespan. It also ensures that the battery operates within an ideal temperature range, which boosts energy efficiency, increases driving range, and enhances safety. Inadequate thermal management can result in problems such as thermal runaway, where excessive heat triggers a dangerous cycle of rising temperatures, potentially leading to battery failure or fire. Thus, maintaining the right heat balance is essential for optimizing battery performance and longevity in electric vehicles.

Common materials for managing heat in electric vehicle (EV) batteries include aluminum, copper, and graphite. Aluminum is well-regarded for its excellent thermal conductivity and is frequently used in battery casings and heat sinks to help dissipate heat and avoid overheating. Copper, known for its high thermal and electrical conductivity, is often found in battery connections and terminals, promoting effective heat dissipation and energy transfer. Graphite, which is typically used as the anode material in lithium-ion batteries, not only enhances electrical conductivity but also aids in evenly distributing heat across the battery cells. Together, these materials play a crucial role in maintaining stable temperatures for safe and efficient battery performance.

A.G. Olabi, H. M. (2022, August). Battery thermal management systems: Recent progress and challenges. Retrieved from Science Direct: https://www.sciencedirect.com/science/article/pii/S2666202722000350

G. Amba Prasad Rao, S. S. (2024, June). A review of integrated battery thermal management systems for lithium-ion batteries of electric vehicles. Retrieved from Science Direct: https://www.sciencedirect.com/science/article/pii/S2772671124001086