May 3, 2024

The Transient Line Source (TLS) method is a well-established, absolute technique for measuring the thermal conductivity of soil, rocks, concrete and polymers. Understanding the thermal properties of materials is crucial across various applications and enables one to achieve the best performance out of the materials used.

This method of testing thermal properties has accelerated development in construction, environmental, renewable energy and even the aerospace industries over the past 70 years. Providing accurate data is essential for:

The TLS method is a powerful and versatile technique for measuring TC across different materials. Let’s explore its principles, applications, and advantages.

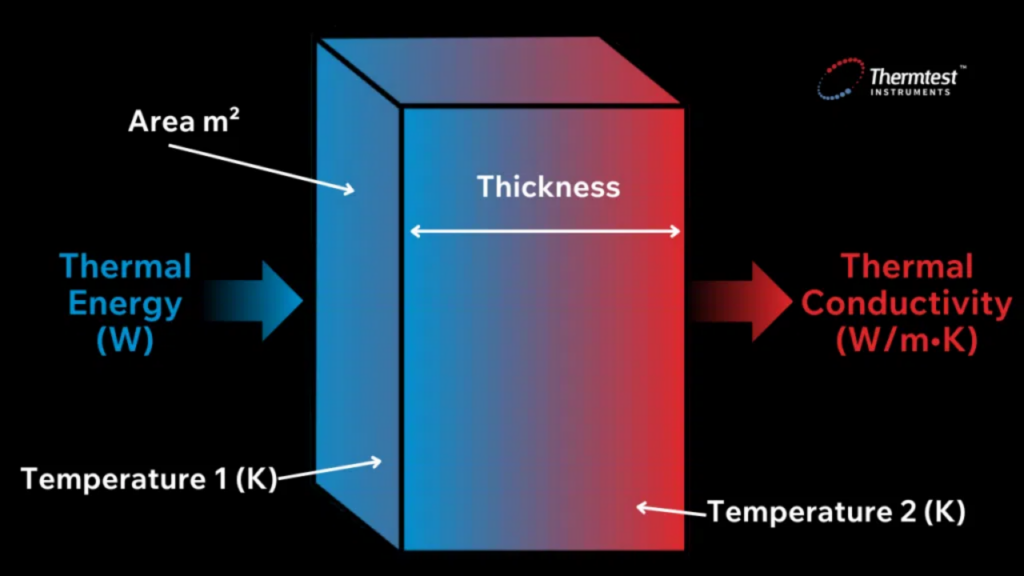

Thermal conductivity (k) refers to a material’s ability to transfer heat. In other words, it is the rate at which heat can pass through a specific material. Materials with high thermal conductivity, like metals, conduct heat efficiently, while those with low TC, like insulators, resist heat transfer.

Figure 1. Diagram depicting thermal conductivity.

Precise TC measurements are vital for various industries, including aerospace, construction, manufacturing, technology and medical. TC is essential for understanding how well a material will aid or restrict heat flow and how well a material will perform over its expected lifespan.

There are several methods for measuring thermal conductivity, but the 3 standard methods are:

Schleiermacher first reported the earliest mention of the transient line theory in 1888 during his research on the thermal conductivity of gases. In 1931, Stalhane and Pyk developed the first cased probe for the transient hot wire method. However, it was not until 1950 that Hooper and Lepper elaborated on the theory after recognizing the limitations of the guarded hot plate method. Not long after, Hooper and Chang developed the first official thermal probe in 1953.

The Transient Line Source (TLS) method is a straightforward, portable method for testing the thermal conductivity of various materials, mainly soil, rocks, concrete, and polymers. The TLS method utilizes a long, thin needle or probe that acts as a heat source and a resistance thermometer. The needle is inserted fully into the sample, and the material is heated for a set time while temperature measurements are taken at constant intervals. During the cooling period, temperature readings are retaken at the same intervals.

Calculate the thermal conductivity of the sample using the obtained data and the following equation:

k= q/4πa

where k is the thermal conductivity in W/mK, q is the needle’s heating power, and a is the slope of the line for temperature rise over the log of time.

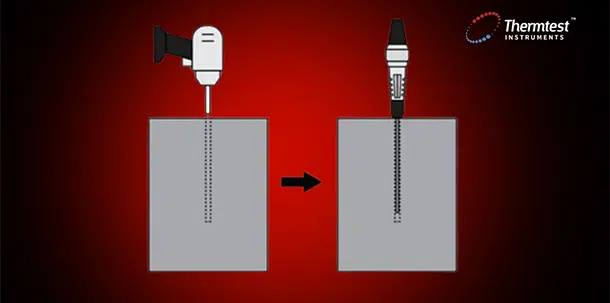

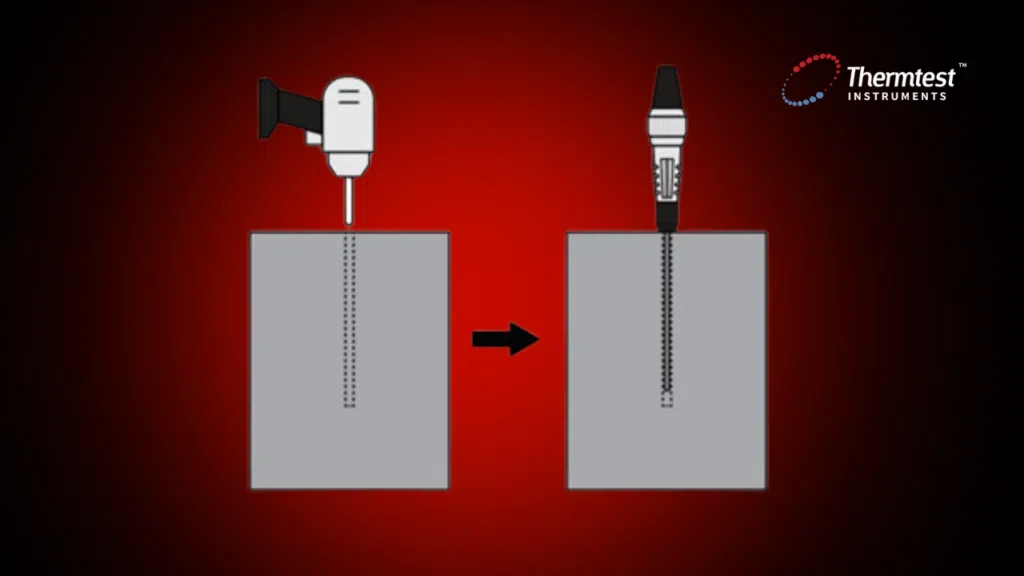

To set up the measurement with the TLS method, you must create a hole in the sample’s center with the same diameter and length as the needle. For soft samples like dirt, you can use a poker tool to make the hole. However, for more challenging samples like rock and concrete, you must use a tiny drill bit to form a hole for the sensor. Thermal paste should be applied to the needle probe when testing a drilled, non-uniform or solid material to minimize any effects of contact resistance.

Once inserted into the sample, allow ten minutes for the sample and sensor to become isothermal. The needle delivers heat into the sample at a constant rate during measurement and records the temperature over a defined period. Afterwards, use the slope of the plot to calculate thermal conductivity (k).

Figure 2. A visual guide showing how the TLS method works.

Scientists predominantly measured the thermal properties of materials using the Guarded Hot Plate (GHP) method before developing the TLS method. This technique must be measured under laboratory conditions, often requiring long test times and large sample sizes; hence, why the concept of a highly portable transient probe that required little setup was highly desirable. The rugged design of the TLS probe allows for laboratory or field testing and has several advantages over other TC measurement techniques.

One of the main advantages of the TLS method is its portability. The rugged design allows this method to give accurate in situ and laboratory measurement results with a simple sample setup. Compared to other methods, the TLS technique is quick, easy to use and reliable. This method has proven to work even when testing porous materials containing moisture. Steady-state methods cannot account for the variability that moisture evaporation and condensation have on thermal conductivity, and therefore, the transient line method gives the most accurate results.

Figure 3. The TLS method is the preferred method in the construction industry. The Transient Line Source method has applications across various industries, the most common of which are construction, renewable energy, and environmental technology. This method is highly preferred in the construction industry as it is less destructive and can account for moisture inside the building and insulation materials. Due to its superior soil testing capabilities, this method has also become increasingly popular in environmental studies, including pipelines and underground powerlines.

While the TLS method offers significant benefits, it’s essential to compare it with other standard techniques like the Transient Plane Source (TPS), Transient Hot Wire (THW), and Heat Flow Meter (HFM) techniques.

The TPS method incorporates a disk-shaped sensor placed in contact with the surface of the sample material. A heat pulse is sent through the sensor, and the resulting rise is recorded. The thermal conductivity of the sample material is then calculated based on the rate at which the sensor’s temperature returns to its original state. This method works best for testing solids, pastes, and powders.

The THW method consists of a thin heating wire fully immersed in a small sample volume to be measured. A current is sent through the wire, heating not only the wire but also the sample. The electrical resistance in the wire is measured over time, and from there, the thermal properties of the test sample can be determined. The THW method tests the thermal properties of liquids and phase-change materials.

The HFM is a steady-state method of determining the thermal conductivity of insulation and construction materials. This method places a sample between two plates of known temperature difference. The rate of heat flow through the sample is then measured, and thermal conductivity can be calculated based on sample dimensions.

Compared to other techniques, TLS can test many materials, including soil, rocks, concrete, polymers, moist and porous materials and even liquids. This method is also highly portable, compact, and inexpensive. Unlike the steady-state HFM method, TLS does not require in-lab testing or large sample sizes. The TLS method often presents a more versatile and efficient alternative, especially for diverse material types.

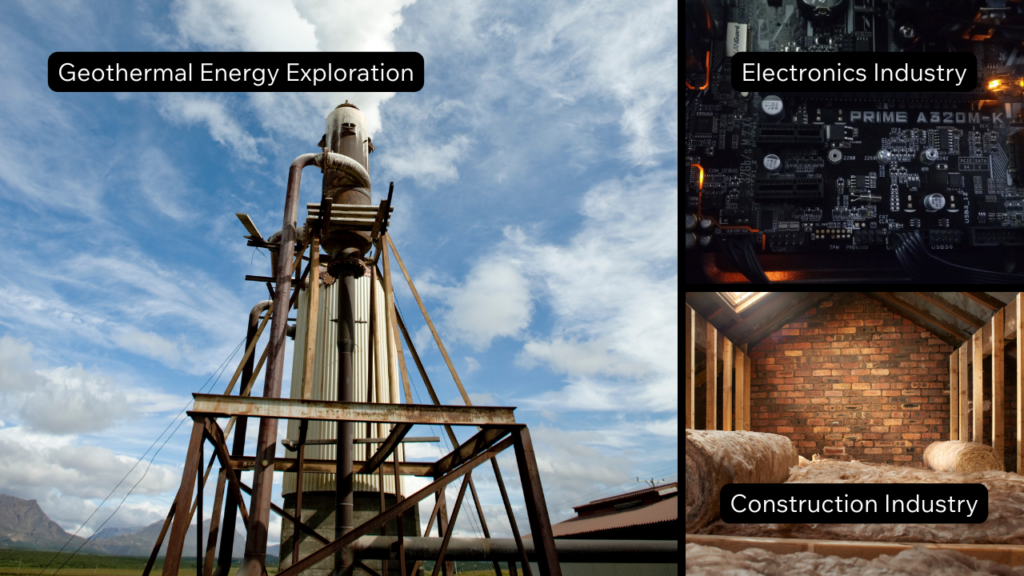

The TLS method has demonstrably impacted various industries. Here are a few examples highlighting its diverse applications:

Figure 4. Real world applications of the TLS method include energy efficiency in buildings, road safety, and space exploration.

Figure 5. Real world applications of the TLS method include the food science industry and pharmaceutical manufacturing.

Figure 6. Real world applications of the TLS method include the electronics industry, geothermal energy exploration and the construction industry.

To achieve accurate and reliable results with the TLS method, follow these essential guidelines:

Adhering to these best practices can maximize the effectiveness and reliability of your transient line source measurements, leading to accurate and trustworthy thermal conductivity data.

The Transient Line Source (TLS) Method effectively measures various samples’ absolute thermal conductivity and resistivity, including soil, concrete, and polymers. Compared to others, one of the significant advantages of this method is its fast test time, portability, and ability to test porous and moist materials. Knowing and understanding the thermal conductivity of materials enables individuals to achieve the best performance out of items used in everyday life.

The TLS method is straightforward and reliable, with endless applications in construction, energy, and environmental industries. As the demand for accurate thermal conductivity data continues to grow, the TLS method is poised to play a vital role in material selection, process optimization, and technological advancements across various fields.

Transient Line Source (TLS) is a method of measuring thermal conductivity. It works by fully submerging a needle (probe) into a sample and heating it for a set period. During this period, temperature readings are taken at regular, constant intervals. Once complete, temperature readings are taken at the same intervals during the cooling period. Thermal conductivity is then calculated from the obtained temperature data.

Transient analysis evaluates how a system responds to boundary conditions over time. It involves determining temperatures and other thermal quantities that vary with time. So, unlike steady-state thermal analysis, time is significant with transient measurements.

Transient analysis involves measurement as a function of time, whereas static analysis shows a measurement at a single point in time. Steady-state methods require that the sample and reference pieces be at thermal equilibrium prior to measurements beginning. Transient methods do not require this rule to be fulfilled and, therefore, provide results more quickly.

Thermtest’s TLS-100 presents field researchers the opportunity to measure the thermal properties of organic materials, such as soils and concrete. This instrument relies on the Transient Line Source (TLS) technique to provide efficient and accurate thermal conductivity readings of soils, powders and solids, ranging in thermal conductivities of 0.1 to 5 W/mK.

Batty, W. J., Probert, S. D., Ball, M., & O’Callaghan, P. W. (1984). Use of the thermal-probe technique for the measurement of the apparent thermal conductivities of moist materials. Applied Energy, 18(4), 301–317. doi:10.1016/0306-2619(84)90011-4

Brostr̲m, T., Nilsen, L., Carlsten, S., & Banfill, P. F. G. (2018). Hygrothermal properties of NHL mortars. In Conference report the 3rd International Conference on Energy Efficiency in historic buildings (pp. 71–79). essay, Uppsala University.

Burger, N., Laachachi, A., Ferriol, M., Lutz, M., Toniazzo, V., & Ruch, D. (2016). Review of thermal conductivity in composites: Mechanisms, parameters and theory. Progress in Polymer Science, 61, 1–28. https://doi.org/10.1016/j.progpolymsci.2016.05.001

Byzyka, J., Rahman, M., & Chamberlain, D. A. (2018). An innovative asphalt patch repair pre–heating method using dynamic heating. Construction and Building Materials, 188, 178–197. doi:10.1016/j.conbuildmat.2018.08.086

de Wilde, P., Griffiths, R., & Goodhew, S. (2008). Validation of data analysis routines for a thermal probe apparatus using numerical data sets. Building Simulation, 1(1), 36–45. https://doi.org/10.1007/s12273-008-8105-0

Marovelli, R. L., & Veith, K. F. (1966). Thermal conductivity of rock: Measurement by the Transient Line Source Method. United States. Bureau of Mines.

Method comparison. Thermtest. (2021, June 1). https://thermtest.com/thermal-resources/compare-thermal-conductivity-measurement-methods

Pilkington, B., Wilde, P.D., Goodhew, S., & Griffiths, R.F. (2006). Development of a probe for measuring in-situ the thermal properties of building materials.

What is thermal conductivity? . Thermtest. (2018, November 26). https://thermtest.com/what-is-thermal-conductivity

Zent, A. P., Hecht, M. H., Cobos, D. R., Wood, S. E., Hudson, T. L., Milkovich, S. M., DeFlores, L. P., & Mellon, M. T. (2010). Initial results from the thermal and electrical conductivity probe (TECP) on Phoenix. Journal of Geophysical Research, 115(3). https://doi.org/10.1029/2009je003420