April 3, 2023

Have you ever considered using pineapple leaves to insulate your home? How about straw or an old pair of jeans? Surprisingly, these unconventional and bizarre materials are frequently being repurposed for use as insulation within the walls or roof of a building or home. The unconventional use of these common materials as insulation stems from the unique thermal resistance and the environmentally friendly properties they possess. As our thermal conductivity testing capabilities increase, so do our options for eco-friendly insulation materials.

Throughout the last decade, a number of influential scientific studies have emphasized the ill effects largely synthetic materials are having on the state of the environment. Polystyrene, EPS and XPS foam are a few examples of insulation materials that are made from unnatural substances manufactured from a variety of petrochemicals sourced using fossil fuel-reliant extraction methods. Other popular homes and building insulation materials such as mineral wool and glass demand an alarming amount of energy to produce. In most cases, this also depends on the availability of non-renewable resources. These conventional insulation materials are tough on the environment throughout their entire production stage and continue to inflict harm past their useful life as they are often non-recyclable. They can take anywhere from decades to centuries to decompose naturally.

Figure 1: Expanded polystyrene home similar to that sold at a home improvement store.

As part of an ongoing effort to characterize and develop innovative insulation materials, researchers have presented several different natural and sustainable insulation materials that can serve as an effective replacement for conventional polystyrene foam products. Due to the novelty associated with these materials, their complete insulative performance over their useful life is still unknown, however, data-driven estimates have predicted that many of these materials can insulate a home just as effectively as their synthetic counterparts.

This article presents some of the more extensively researched eco-friendly insulation materials that are starting to gain momentum in the construction industry. The list continues to grow as new materials are being tested for insulative applications to determine their effectiveness in acting as suitable replacements.

The effectiveness of insulation material is a function of its thermal resistance (R-value) and specific heat. The R-value of a material is a way of indicating insulation effectivity and is calculated by dividing the thickness of a material by its thermal conductivity. Materials with a higher R-value will have improved resistance to heat flow and perform better as insulation material.

An R-value represents the temperature difference that occurs per unit of material thickness and is normally measured in increments of one inch. Ideally, wall and roof insulation should have a cumulative R-value of at least 30 with values closer to 60 being recommended for structures located in Northern climates that are exposed to colder temperatures. A higher R-value can be achieved by increasing insulation thickness; however, this can drive up project costs and demand additional maintenance from wear and tear.

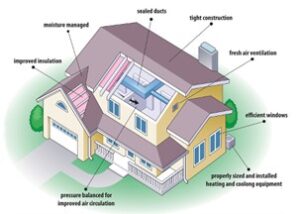

Figure 2: Example of an energy-efficient home as proposed by the government of Ontario.

Without high-quality insulation, homes demand an additional amount of energy to maintain a stable internal temperature. This can cause utility bills to skyrocket and lead to an increased amount of greenhouse gas emissions. It is estimated that a poorly insulated roof can be blamed for over 35% of heat loss that occurs in a home or building with the walls being responsible for an additional 25% of heat loss if they lack adequate insulation as well.

Regardless of the type of material used, ensuring a home has an effective amount of high R-value insulation is an excellent step towards improving the energy efficiency and environmental impact of a structure. Improving energy demands by keeping more heat contained within a structure will, in turn, lower the amount of greenhouse gas emissions released by a home. That being said, there are still a number of ways to make a home even more sustainable by selecting an eco-friendly insulation material to provide the thermal barrier instead of using a highly synthetic and heavily manufactured insulation material. Some eco-friendly insulative materials that are currently being explored for their potential use in homes and buildings include:

Sheep’s wool can be used for much more than making products like a cozy sweater or pair of socks. Recently, this naturally fire-resistant material has been repurposed for use as an insulation material in homes providing them with that same heat loss protection that a warm sweater would to its wearer. When wool fibres are compressed, they form small air pockets that disrupt the movement of heat through the material. Air naturally has a high thermal resistance value so materials that are highly porous will also have a lower conductivity overall.

Sheep wool can absorb moisture without having its thermal insulation abilities compromised. This can be extremely beneficial to a home that might experience a leaky roof or water infiltration. Additionally, wool is classified as a renewable material. If it is collected in a sustainable and ethical manner, it can take only one year for a sheep to regrow its wool.

Figure 3: Repurposed sheep’s wool for insulative applications.

The wool that is used to insulate a home normally contains an average of 5-20% polyester to help increase its strength and make it easier to mould the material into desirable panel shapes. A complete cradle-to-grave perspective of sheep wool as an insulation material demonstrates its superiority in terms of its ethical origin, limited manufacturing demands, and ability to be clean and recycled for countless additional applications following its useful life as a home insulation material. On average, a single 24-inch roll of R-13 wool costs roughly $60 USD with the R-value of a single inch of material generally in the range of 3 to 4.

A relative newcomer to the eco-insulation market, Icynene is a spray foam made from castor oil that rapidly expands to over 100x its natural volume when released into a wall or roof cavity. This material has proven to be extremely effective at sealing air leaks and drafts as well as buffering noise levels between the walls in a structure. When Icynene expands, it traps tiny air bubbles throughout it that act as the main resisters to heat loss. As stated previously, air has a naturally low thermal conductivity and incorporating it throughout a material can help increase the thermal resistance of the entire medium. One pitfall of Icynene is ironically its strong sealing power. This spray foam creates such a tight seal in the building envelope that it requires a ventilation system to be installed along with it. This has a massive impact on the upfront costs of the initial installation process; however, it will result in drastic cuts to a home’s energy bill post-installation. Icynene has an R-value of 3.6 per inch of thickness and can lead to a 30-50% reduction in home energy bills in just a single year.

Figure 4: Icynene insulation boards

Discovered in the 1930s, Aerogel quickly rose to fame in the insulation industry. Often referred to as the ‘superman’ of insulation material, Aerogel has an R-value of 10.3 per inch, one of the highest in the market. This manufactured material offers some of the highest quality thermal protection and is made by removing liquid from silica under extremely high pressures. This process leaves behind a material that had a volume consisting of 90% air. This unique molecular structure does not leave much room for movement, making it almost impossible for gas-phase conduction or convection to occur.

Figure 5: Aerogel insulation rolls.

Although the aerogel’s structural framework is composed of silica, other materials such as copper, iron oxide, gold, and organic polymers could be incorporated into the material. These additional materials make up less than 5% of the overall volume of aerogel as the remaining 90-95% is air. It also has impressively high water-repelling capabilities and can prevent corrosion and moisture damage to the key insulating regions of the material.

Aerogel is extremely lightweight and normally sold in sheets or stickers for easy installation. The high thermal resistance and simplicity of aerogel insulation do come at a cost as a single inch of material has a price tag of almost $2 an sq. Ft.

Cotton and denim are two insulation materials that often get overshadowed by the highly technical, scientific materials that dominate the market. Cotton and denim insulation is almost always made from recycled materials. Repurposed fabrics and jeans make cellulose insulation one of the greenest materials on the market. Like fibreglass insulation, cotton can be rolled into batts and has an R-value of 3.2-3.7 per inch of thickness. Unlike fibreglass, cotton insulation doesn’t contain any formaldehyde which has been linked to cancer and isn’t associated with inflicting respiratory problems.

Figure 6: Denim insulation installed in batts.

To maintain cotton’s resistance to fire, it is treated with a non-toxic chemical known as boric acid. Cotton naturally has a high resistance to moisture and insect infiltration, which are both known pitfalls of many other eco-insulation materials. These perks of denim and cotton insulation do come at a cost to the consumer as they cost on average 10-50% more than fibreglass insulation per square foot.

Cork is a unique material that differentiates itself from other eco-friendly insulation by also having a negative carbon footprint. Cork insulation is made from the outer bark of oak trees and is 100% natural, eco-friendly, and recyclable. Biological materials (such as bark from trees) are known as carbon sinks. This means they can absorb excess carbon dioxide from their surrounding environments even when installed within the walls of a home. The carbon-capturing capability of cork, combined with its resistance to mould and moisture infiltration makes it arguably the most eco-friendly insulation material of them all.

Figure 7: Cork insulation.

Most of the cork repurposed for insulation is sourced from farms in Portugal despite being native to the Mediterranean and North African regions. Due to the unique and limited availability of cork, the insulation is relatively costly compared to its synthetic counterparts. This makes cork insulation unappealing to price-sensitive customers despite the range of environmental and thermal benefits it provides over the duration of its extremely long useful life.

Despite the ongoing effort of researchers to emphasize the importance, availability and variety of green materials that can be used for insulative purposes, most builders and retrofitting professionals continue to select non-renewable materials as their primary choice of insulation. Much of this preference towards energy-demanding insulation products, such as polystyrene and mineral wool, reflects the considerable cost advantage they have over biobased materials due to their market dominance. Many professionals in the construction industry also lack a general sense of awareness regarding the environmental footprint a lot of insulation materials have. This is likely the result of the poor advertising campaigns and media coverage of these materials combined with the fact many insulation retailers deem eco-friendly metrics as being irrelevant to the size of their bottom line.

The onus is on all participating parties in this supply chain to broaden their perspective to include factors such as material production demands, raw materials required, total home energy savings, and insulation recyclability when choosing a material that will perform the best once installed within a structure. With home heating and cooling consistently requiring the largest percentage of all energy usage in a building, it is crucial to focus on keeping as much heat as possible inside the house to reduce this demand. Ideally, this can be achieved by blocking heat flow with materials that won’t impose harm on our natural world before, during and after their useful life as an insulation material.

7 eco-friendly insulation alternatives for a green home. (2019, January 4). Inhabitat – Green Design, Innovation, Architecture, Green Building | Green Design & Innovation for a Better World. https://inhabitat.com/7-eco-friendly-insulation-alternatives-for-a-green-home/

Asdrubali, F., D’Alessandro, F., & Schiavoni, S. (2015). A review of unconventional sustainable building insulation materials. Sustainable Materials and Technologies, 4, 1–17. https://doi.org/10.1016/j.susmat.2015.05.002

Clo—Clothing and Thermal Insulation. (n.d.). Retrieved February 5, 2022, from https://www.engineeringtoolbox.com/clo-clothing-thermal-insulation-d_732.html

ecomike. (2015, May 1). Why use Cellulose Insulation « Eco Insulation | Go Green. Save Green. Eco Insulation | Go Green. Save Green. https://ecoinsulation.ca/cellulose-insulation/

Liza. (2022, July 7). The Essential Guide to Eco-friendly Home Insulation (2023). MindsetEco. https://mindseteco.co/eco-friendly-insulation/

News ·, D. B. · C. (2016, December 8). Wool: The innovative home insulation you won’t buy | CBC News. CBC. https://www.cbc.ca/news/canada/nova-scotia/wool-insulation-home-sheep-dalhousie-university-1.3887057

Residential Buildings Factsheet. (n.d.). Center for Sustainable Systems. Retrieved November 28, 2022, from https://css.umich.edu/publications/factsheets/built-environment/residential-buildings-factsheet

Ten materials that store carbon and help reduce greenhouse gas emissions. (2021, June 27). Dezeen. https://www.dezeen.com/2021/06/27/carbon-negative-carbon-neutral-materials-roundup/

Top 5 Green Insulation Options. (2011, February 15). HowStuffWorks. https://home.howstuffworks.com/home-improvement/construction/green/5-green-insulation-options.htm

Writer, T. R., Rise. (2020, October 5). Cellulose Insulation: Sustainable and High-Performance. Rise. https://www.buildwithrise.com/stories/cellulose-insulation