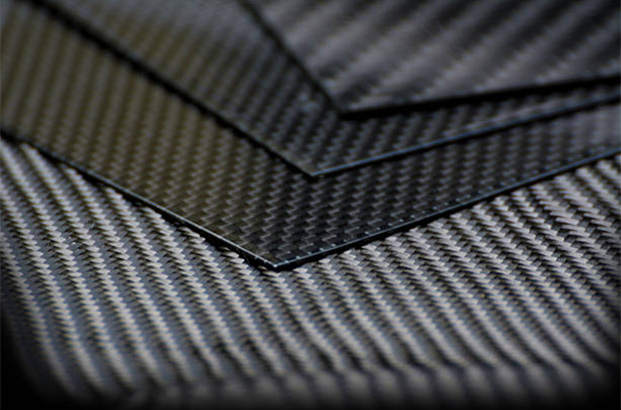

Applications > Composites

The composites industry merges materials science and engineering to produce materials with superior properties for aerospace, automotive, sports, and construction. Thermal analysis is crucial for understanding composites’ behavior and thermal stability. It aids in material selection, processing, and predicting lifespan under varied conditions. Designing composites to withstand thermal expansion is vital, especially in aerospace and automotive sectors.

Thermal analysis optimizes composition and processes to enhance performance and reliability. Sustainability drives development of eco-friendly composites, supported by thermal analysis to ensure performance standards are met. Advanced thermal analysis techniques drive innovation, delivering efficient, durable, and sustainable materials to meet industry demands.

Thermtest instruments help customers gain valuable insights into thermal properties of their materials.