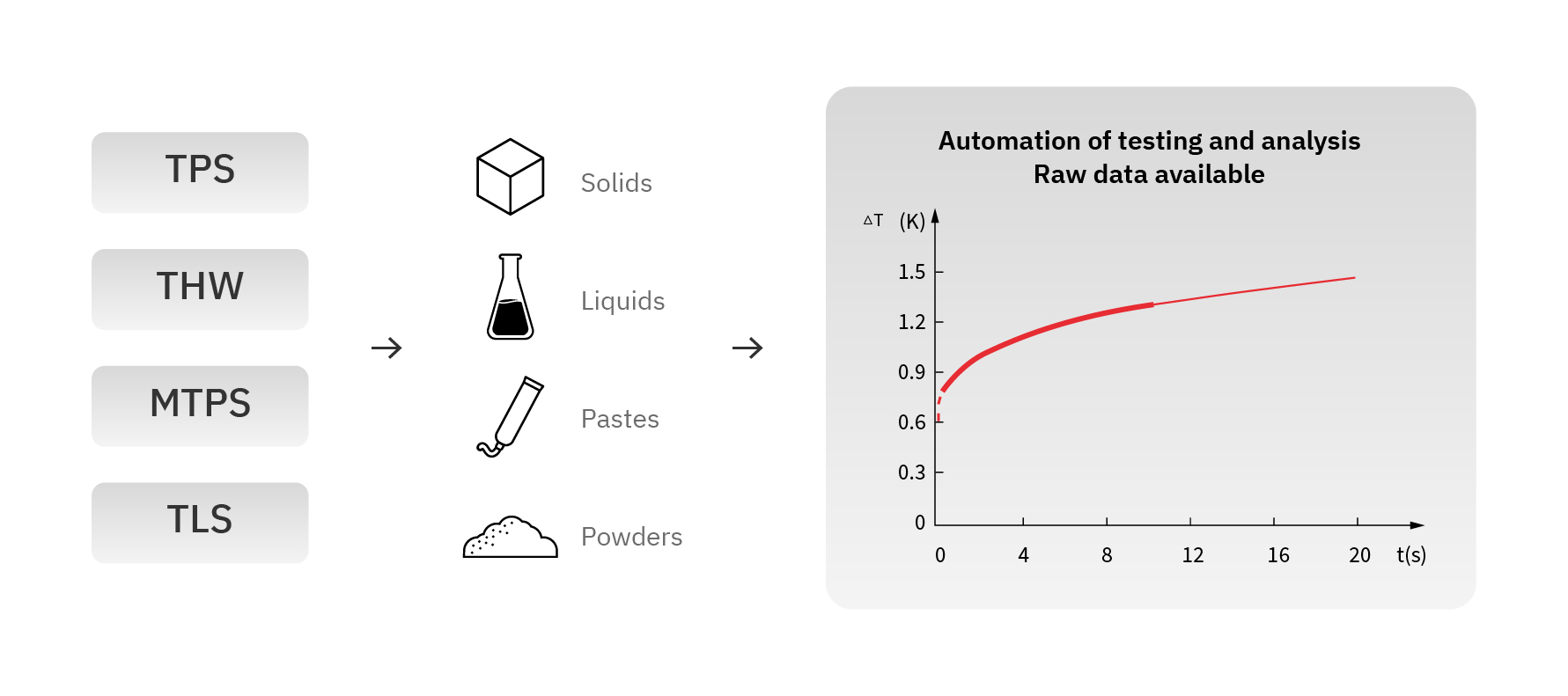

Versatile measurement platform with accurate methods for thermal conductivity, thermal diffusivity, specific heat and thermal effusivity of solids, liquids, pastes and powders.

Transient methods share similar theory with differences that are specific to their primary design.

The sensors are electrically connected to a power supply and sensing circuit. A current passes through the sensors and creates an increase in temperature, which is recorded over time. The heat generated is then diffused into the sample at a rate dependent on the thermal transport characteristics of the material.

Intelligent transient design for automation of testing and analysis. Raw data is always available to empower understanding of your results. Name your sample, iTransient does the rest.

The mid-range MP-V includes two primary test methods for thermal conductivity, thermal diffusivity, specific heat and thermal effusivity. Conforming to international standards, the transient plane source (TPS) and transient hot wire (THW) are designed specifically for their primary applications. As MP-V methods are absolute, the thermophysical results are calculated from the raw-data, with no need for contact agents or calibration.

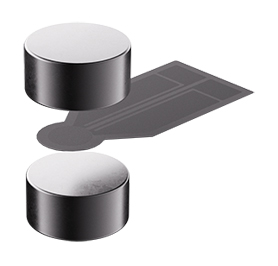

The TPS sensor designed for solids, pastes, and powders is comprised of a double-spiral of nickel encapsulated between layers of insulation (Kapton). Standard operation of this sensor (two-sided) is placed between two pieces of the same sample.

Our proprietary TPS calculation model measures the contact resistance between the sensor and sample, as well as the thermal conductivity, thermal diffusivity, volumetric specific heat, and thermal effusivity of the sample.

The THW sensor designed for liquids and phase change materials (PCMs) consists of a replaceable thin heating wire secured to a specially designed sensor and sample cell.

This allows back pressurizing liquids to measure thermal conductivity, thermal diffusivity, and volumetric specific heat past boiling temperatures. Measurements are done at short test times (1 second) to limit convective effects on samples with a wide range of viscosities.

The MTPS sensor is configured for asymmetric (single-sided) testing, ideal when only one piece of sample is available. The sensor (ISO 22007-7) follows the same principles of operation as the TPS method.

This sensor can be used with the Bulk, Anisotropic, Slab, and 1-D TPS modules.

The TLS sensor designed for soil, pastes, and polymers. The sensor is completely inserted into the sample to be tested. Heat is delivered to the sample using a constant current source and the temperature rise is recorded over a defined period of time.

The slope from the plot of temperature rise versus logarithm of adjusted time is used in the calculation of thermal conductivity.

Bulk thermal conductivity, thermal diffusivity, specific heat and thermal effusivity. Symmetric and asymmetric.

Anisotropic In-plane and out-of-plane thermal conductivity and thermal diffusivity. Symmetric and Asymmetric.

Isolated in-plane thermal conductivity, thermal diffusivity, and volumetric specific heat of sheets. Symmetric and asymmetric*.

Thermal conductivity of thin-films and coatings according to ISO 22007-2.

High accuracy direct measurement of specific heat. Various cell dimensions available for improved accuracy of heterogenous materials.

Isolated out-of-plane thermal conductivity, thermal diffusivity, and volumetric specific heat for short and tall elongated shapes, rods, and bars. Asymmetric.

* Modified Transient Plane Source (MTPS) only

| Methods | TPS | THW | MTPS | TLS |

| Materials | Solids, pastes and powders | Liquids and PCMs | Solids, pastes, and powders | Soil, pastes, and polymers |

| Testing modules | 3-D: Bulk, Anisotropic, Slab, Thin-Film. General: Specific Heat |

Bulk | 3-D: Bulk, Anisotropic, Slab. 1-D: Standard, 1-D Slab |

Bulk |

| Thermal conductivity (W/m·K) | 0.01 to 500 | 0.01 to 2 | 0.03 to 500 | 0.1 to 8 |

| Thermal diffusivity (mm²/s) | 0.01 to 300 | Up to 0.5 | 0.01 to 300 | N/A |

| Specific heat (J/kg-K) | Up to 5 | Up to 5 | Up to 5 | N/A |

| Thermal effusivity (W√s/m²K) | 20 to 40000 | N/A | 20 to 40000 | N/A |

| Sample size (mm | mL)* | 10 diameter or square | 20 mL | 25 diameter or square | 50 diameter |

| Sample thickness (mm)* | 0.05 | N/A | 0.1 | 100 length |

| Largest sample size (mm) | Unlimited | Unlimited | Unlimited | Unlimited |

| Test time (seconds) | 2 to 160 | 1 | 2 to 160 | 180 |

| Accuracy (Thermal conductivity) | 5% | 2% | 5% | 5% |

| Repeatability (Thermal conductivity) | 2% | 1% | 2% | 2% |

| Temperature range (°C)** | 0 to 300 -75 to 300 |

-50 to 200 |

0 to 100 | -50 to 200 |

-40 to 100 |

| Sample configuration | Symmetric (Two-Sided) | Asymmetric (Single-Sided) | Inserted | Asymmetric (Single-Sided) | Inserted |

| Standard | ISO 22007-2:2022, ISO 22007-7:2023, GB/T 32064-2015 |

ASTM D7896-19 | ISO 22007-7:2023 | ASTM D5334-22a, ASTM D5930-17, IEEE 442-2017 |

* Based on testing module used.

** For temperature, external control required.

We are happy to arrange a live demonstration for you!