May 21, 2024

Understanding the thermal properties of materials is crucial in various industrial applications, particularly when dealing with high temperatures. This article delves into an experiment conducted in our lab utilizing the TLS-100, a portable and precise thermal conductivity testing device, to analyze the thermal conductivity and resistivity of two intriguing materials: steatite and bisque-fired alumina.

These materials are renowned for their heat-resistant properties and insulating nature, making them valuable assets in diverse industrial sectors. By delving deeper into their thermal behaviour, we gain valuable insights for optimizing their use in various applications.

Steatite, or soapstone, is a naturally occurring mineral composed primarily of talc, magnesium silicate, and minor amounts of other minerals. Its unique composition grants it exceptional properties, including:

Bisque-fired alumina is a specific form of aluminum oxide (Al2O3) that has undergone a partial sintering process. This process involves:

This partial sintering grants bisque-fired alumina several key characteristics:

Once you achieve your desired shape, the bisque-fired alumina undergoes a final sintering process, fully densifying the material and significantly increasing its strength and hardness.

This final product is widely used in:

The TLS-100 is a portable and versatile thermal conductivity testing system. It utilizes the Transient Line Source (TLS) method, a well-established technique for measuring thermal conductivity and resistivity in various materials. This allows for convenient testing in the lab and in the field. The system performs measurements in accordance with ASTM D5334 —Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure.

This method offers several advantages:

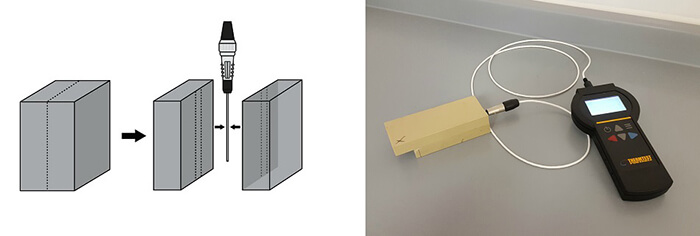

The experiment measured the thermal conductivity of steatite and bisque-fired alumina samples using the TLS-100. The setup comprised the following:

Figure 1. The diagram on the left illustrates the method used to ensure excellent thermal contact between the needle probe of the TLS-100 and the material samples. The photo on the right depicts the two samples of bisque fired alumina during testing.

The TLS-100 completes measurements using the attached needle probe, which acts as the heating element and temperature sensor. Thermal paste is often used with solid samples to achieve maximum contact between the sensor and the sample.

Here’s a breakdown of the specific steps followed:

The experiment’s results revealed remarkable consistency across all five tests for steatite and bisque-fired alumina, highlighting the precision and repeatability of the TLS-100 system.

The mean thermal conductivity values obtained were:

| Test Number | Thermal Conductivity (W/mk) | Thermal Resistivity (mK/W) |

| 1 | 5.005 | 0.199 |

| 2 | 4.953 | 0.201 |

| 3 | 5.137 | 0.194 |

| 4 | 5.181 | 0.192 |

| 5 | 5.108 | 0.195 |

| Mean | 5.077 | 0.196 |

Table 1. Thermal conductivity and thermal resistivity data collected by the TLS-100 on bisque-fired alumina.

| Test Number | Thermal Conductivity (W/mk) | Thermal Resistivity (mK/W) |

| 1 | 3.098 | 0.322 |

| 2 | 3.076 | 0.325 |

| 3 | 3.203 | 0.312 |

| 4 | 3.085 | 0.324 |

| 5 | 3.075 | 0.325 |

| Mean | 3.107 | 0.322 |

Table 2. Thermal conductivity and thermal resistivity data collected by the TLS-100 on steatite.

These values closely align with the accepted reference thermal conductivity values of 3 W/mK for steatite and 5-5.25 W/mK for bisque-fired alumina, validating the accuracy of the TLS-100 measurements. These findings hold significant implications for the industrial applications of steatite and bisque-fired alumina:

The results produced by the TLS-100 showcase the low thermal conductivity of each material, which makes them such effective insulators. The close agreement between the experimental and reference values demonstrates the excellent accuracy of the TLS system, which makes it an ideal choice for thermal conductivity testing.

This study successfully employed the TLS-100 to analyze the thermal conductivity of steatite and bisque-fired alumina. The results provided valuable insights into their thermal behaviour, confirming their suitability for various industrial applications requiring heat resistance and thermal insulation. Further research exploring the thermal conductivity of these materials at varying temperatures and under different processing conditions could offer even more comprehensive data for optimizing their use in diverse industrial settings.

The TLS-100 is a portable thermal conductivity testing system that utilizes the Transient Line Source (TLS) method. A small needle probe is inserted into the material, and a short heat pulse is applied. The TLS-100 calculates the material’s thermal conductivity and resistivity by monitoring the temperature change over time.

The experiment involved:

The experiment yielded consistent results for both materials, with steatite having a mean thermal conductivity of 3.107 W/mK and bisque-fired alumina having a mean thermal conductivity of 5.077 W/mK. These values confirm their low thermal conductivity, making them suitable for heat insulation and temperature control applications.