December 6, 2018

Thanksgiving is over, which means the Christmas trees are going up. Home owners decorate their Christmas trees with ornaments and a Christmas tree topper. Personalized Christmas ornaments can be nice and something unique. Understanding the thermal conductivity of polymers is important to design of 3D printing filaments. With 3D printing, you can now have your own Christmas decorations personalized.

Figure 1. Christmas Tree at Thermtest

3D printing is any of various processes in which material is joined or solidified to create a 3D object. 3D printing filament is created using a process of heating, extruding and cooling plastic to transform nurdles into the finished product.

Various materials are used for 3D printing, most commonly Acrylonitrile butadiene styrene (ABS) filament, Polylactic acid (PLA) filament, Polyethylene Terephthalate (PET) and Polypropylene (PP). These 3d printing materials differ mainly in their melting point, which significantly influences the properties of the final products. Filaments are melted in the print head during the printing process. The temperature range is from 150 °C to 250 °C depending on the technology used. The optimum temperature for the cooling substrate on which printing is carried out is chosen so as to ensure uniform cooling and deformation. It generally varies between (40 – 100) °C. It is clear that both temperatures can significantly affect the properties of the printed 3D object.

It is therefore significant to determine the thermal properties (thermal conductivity, specific heat and thermal diffusivity) of the materials used across a wide range of temperatures.

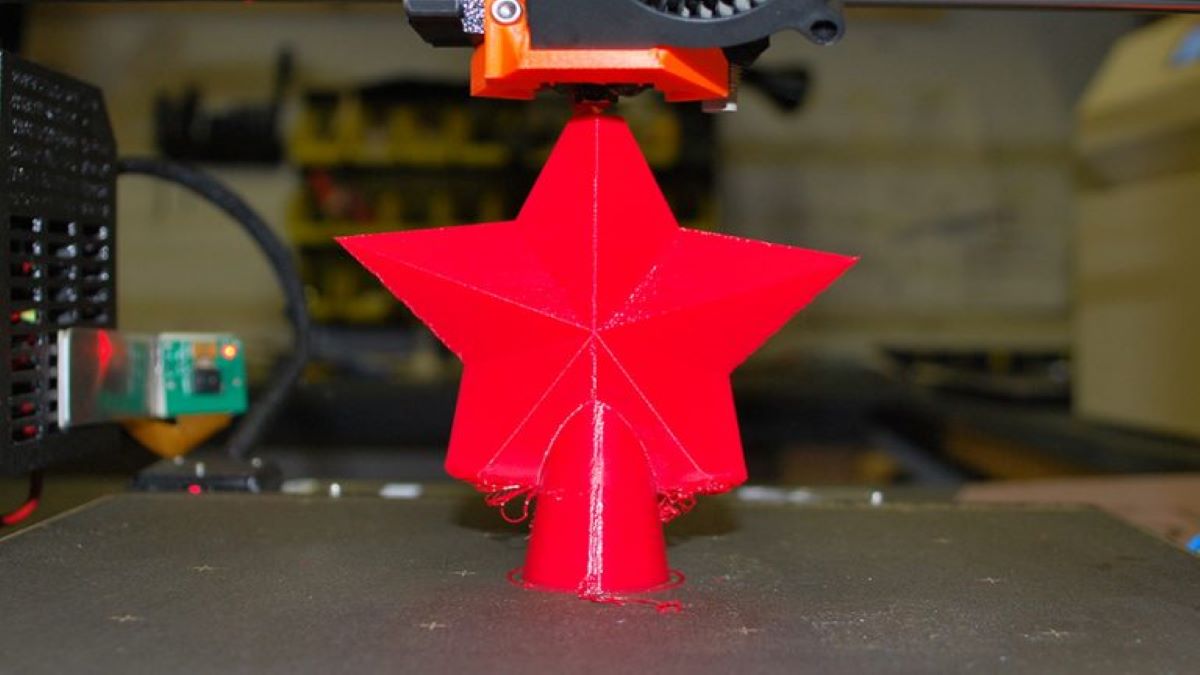

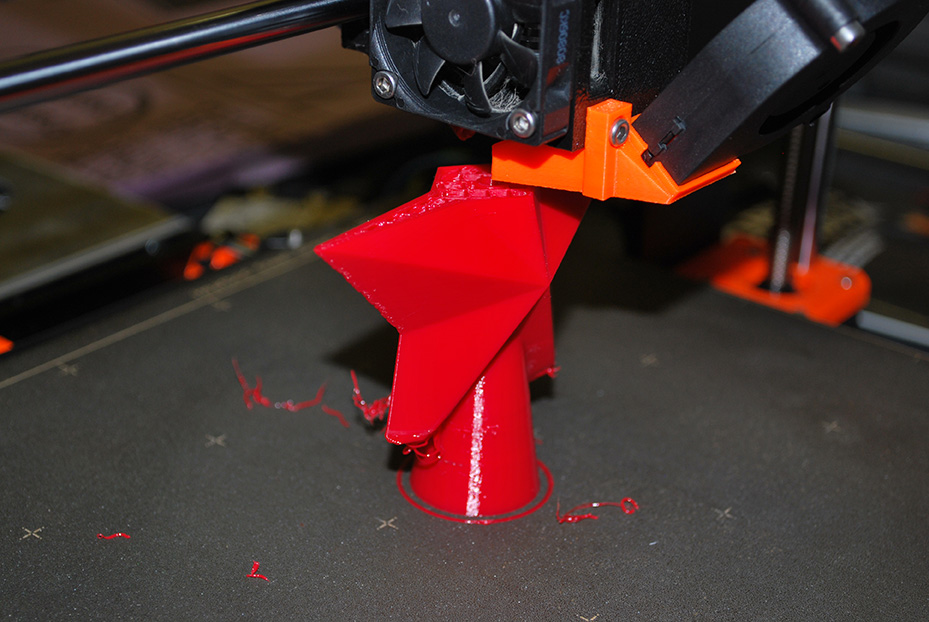

Figure 2. 3D Printing in progress of Christmas Tree Topper

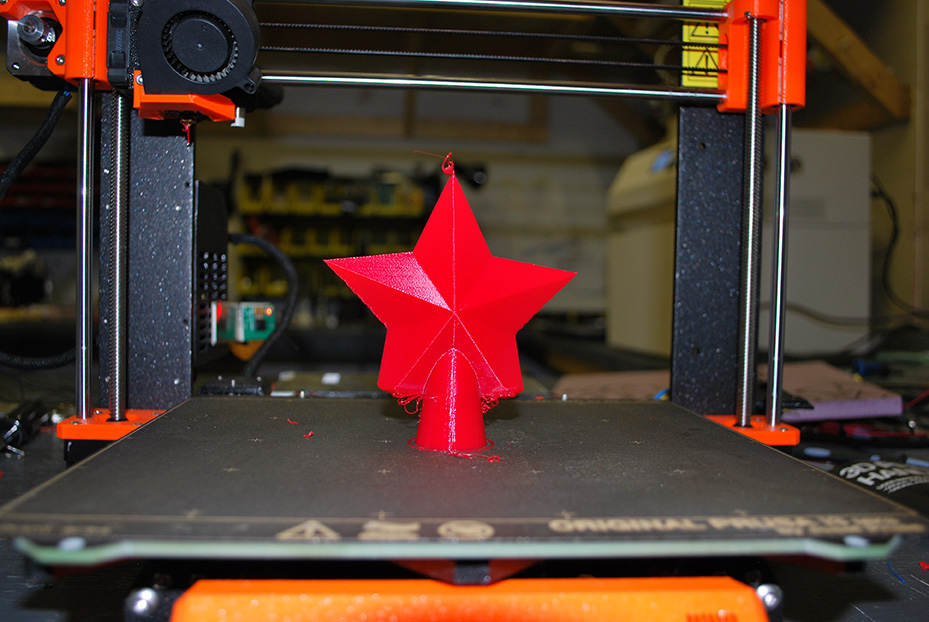

Figure 3. 3D Printing output of Christmas Tree Topper

In the above example, we designed a star Christmas tree topper and sent it to the 3D printer. The support material use is Polyethylene Terephthalate, commonly abbreviated PET. The printing temperature is 240 °C, heated bed temperature is set to 90 °C and printing speed is 120%.

Figure 4. 3D Printing Settings

Custom ornaments can make a great gift to your office staff or any other group of people. So many ideas and so little time. Search the internet or come up with design from your own imagination.

Reference:

https://aip.scitation.org/doi/10.1063/1.4955258

https://www.sciencedirect.com/science/article/pii/S2214860417302324