June 15, 2021

Climate change is a big problem that leaders have been trying to solve since the 21st century began. As public awareness of environmental issues continues to rise, it is also having a more pronounced influence on consumer choice.

People all over the world are trying to live in a more sustainable way. Many countries are experiencing increased production and sale of green technology. This trend particularly affects the construction and building industry. Manufacturers in this market are attempting to make more environmentally friendly products and produce them using sustainable and green techniques.

The popularity of insulative concrete foams (ICRs) has increased because people ae now more interested in products that save energy. They are now using the ICR materials to build new buildings.

ICF is increasingly popular and in demand. As a result, more countries are now producing it. This is mainly for various commercial projects such as apartments, hotels, retail stores, and movie theaters.

Insulative concrete foams are a better and more sustainable option than wooden buildings. They save money and energy in the long run, benefiting the economy and the environment.

Their ability to retain heat is due to limited thermal transfer and movement, as well as possessing a substantial thermal capacity. This successful combination reduces the energy consumption of the structure. It also enhances indoor comfort. It prevents air leaks and provides excellent heat absorption.

Most of the desired thermal properties displayed by ICF are indicated by their high R-value. The “r” in R-value represents resistance. Materials with higher R-values have better resistance to heat flow. This is in comparison to materials with lower R-values.

EPS foam, from which ICF is made, is one of the top insulating materials on the market. ICFs typically contain 5 inches of EPS insulation with testing insulative values ranging between R-22 and R-26.

EPS insulation also possesses optimal sound absorbing qualities. They only allow roughly 12.5% – 25% as much sound to pass through them compared to wooden walls. Business owners find this key component of ICF extremely desirable. This is especially true if the building is located in a loud city street or a downtown metropolis.

Additionally, buildings and homes constructed using these materials offer a level of safety very few building systems can match. They average at being 10x’s stronger than a standard framed structure and several times stronger than CMU ‘cinder block’ construction.

The ICF – EPS combo is popular with the military and law enforcement because it provides blast and ballistic resistance. EPS foam is unique in that it will not burn when exposed to high heat but will melt instead.

EPS foam melts when exposed to these conditions. However, it does not contribute fuel to a fire. This is because all of the leading ICF manufacturers add a flame retardant to EPS foam. This flame retardant gives EPS foam self-extinguishing properties.

Figure 1: Close up of ICF insulation with metal reinforcement.

R-values are important for measuring thermal resistance. However, when evaluating a building’s energy performance, they do not provide enough detail to determine the actual heat transferring properties. Therefore, they should not be the only value considered.

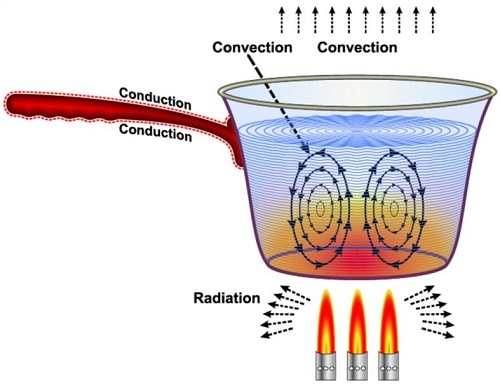

The main factors that are more representative of the energy performance of a building include thermal conduction, convection, radiation, and mass.

Figure 2: Heat exchange mechanisms including thermal conduction, radiation and convection.

The thermal conductivity of material directly relates to its ability to effectively facilitate the transfer of heat through it. Thermal conductivity is the transfer of heat through a material by direct contact between molecules. It is also known as thermal conduction.

Conduction is the only factor that an R-value directly measures. Wood framed insulation has an R-value accessed only in terms of the highest rated component of the wall insulation itself. Most builders will refer to a building as having R-13 or R-21 walls. However, they often fail to mention that these values only represent the highest and most thermally insulative material in the structure.

A wood frame consists of different components with various R-values. This lowers the actual insulation value of the building, sometimes to only half of the advertised value. A wood frame has different components with various R-values, which reduces the actual insulation value of the building.

Sometimes, it can be as low as half of the advertised value. In contrast, ICF walls have a center cavity that holds concrete between two layers of EPS insulative foam. This creates two continuous layers of insulation rated at R-22 or higher.

Figure 3: EPS insulative foam stacks

Despite the focus of insulative materials generally being centered around thermal conduction, it is thermal convection that contributes to the majority of the heat loss occurring in a building. Convection is characterized by heat transfer that occurs through the movement of currents within a fluid or gas. When referring to convection within a building, it is generally the air moving between the inside and the outside of a building or “air filtration” that characterizes the quality of an insulative material.

A common measurement used within the construction industry for describing air filtration is “air changes per hour” at a blower-door induced pressure differential of 50 pascals (ACH50). U.S. energy star standards for new homes require less than 4-7 ACH50. These standards are extremely relaxed compared to the stricter regulations imposed in Canada, which has an R-2000 standard of 1.5 ACH50, and Sweden which requires 0.5 ACH50 or less. In terms of measuring insulative quality, the higher the ACH50 value, the more inside and outside air filtration is occurring.

In a standard wood framed building, convection is experienced as drafts and is often the biggest contributor to energy loss in a building. Air infiltration can account for upwards of 40% of the total energy loss as air frequently leaks through the numerous cracks and joints between the ‘matchsticks’ that make up a wood building shell.

A typical newly constructed wood home will have an ACH50 between 1.75 and 3, however, after a couple of years, this number can skyrocket to values between 5 and 10 as the wood shrinks and deteriorates. Older wooden homes lack almost any insulation and commonly have ACH50 values averaging between 10 and 20.

ICF buildings far surpass a wood framed structure in terms of blocking airflow and maintaining a stable indoor temperature regardless of the external weather or climate. Most ICF buildings display an ACH50 of 0.5-2.5 or less, with these values being heavily dependent on the roof type and sealing material.

This restrictive airflow is beneficial in terms of regulating temperature, however, adequate air exchange must be maintained in these airtight buildings through the use of mechanical ventilation. This type of moderated airflow can be combined with heat/energy recovery units or ground heat exchangers for additional savings.

Thermal radiation is another important regulator of energy use in a building and one that many neglect to consider when selecting a material to use when building a structure. Thermal radiation is characterized by heat transfer through electromagnetic waves which in terms of a building come mainly from UV radiation emitted by the sun.

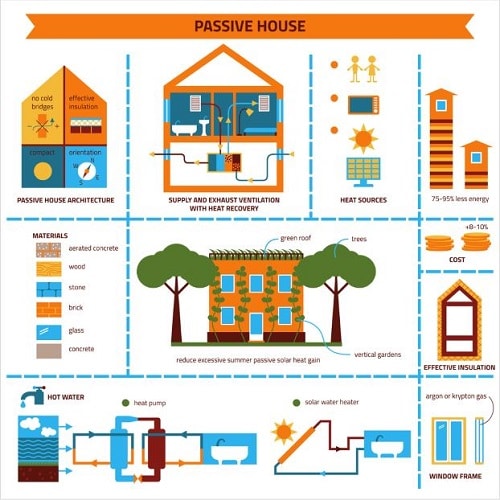

The impact this method of heat transfer can have on the energy exchange that occurs within a building is highly dependent on factors such as site location and the prevailing climate in that region. Passive solar building designs can help optimize a building’s absorption and reflection capabilities through utilizing solar orientation, placement of windows, and selecting ideal shading elements such as choice of finishes and incorporating thermal mass.

Figure 4: Passive house design components extending beyond ICF insulation.

The thermal mass of a material refers to its capacity to store heat. Concrete and adobe bricks have a high thermal mass and act like a battery that stores heat to be released when the surrounding temperature drops. ICF that has a concrete exterior can store heat during the heat of the day and then release it inside at night maintaining a comfortable temperature while using almost zero energy.

In temperate climates, the concrete performs a contrasting role involving passive solar design by letting the strong winter sun warm the high thermal mass walls and floors on the inside and outside of the building. Wood frames have almost no thermal mass, therefore, they offer none of these energy saving benefits. High thermal mass construction can be easily incorporated into ICF walls and floors which will lower the demand for active heating and cooling systems by maintaining a stable surrounding temperature for a longer period.

It is very evident by examining the thermal properties of ICF buildings that they can save more energy and reduce air filtration compared to a standard wood home, but their benefits extend even further beyond the physical properties of the material. Using concrete instead of wood for construction can save a considerable number of trees because the entire wood frame is eliminated.

Many concrete contains recycled components by using supplementary materials such as fly ash or slag to replace a portion of the cement aggregate. Older crushed cement can also be recycled to reduce the need for virgin aggregates and most steel reinforcements used during the construction process also have the potential to be recycled.

Figure 5: Concrete mixture containing larger aggregates.

ICF buildings are a clear champion among construction materials as they offer better economic and environmental benefits compared to standard wood framed buildings. Although the initial construction cost is roughly 3-5% higher for building with ICF materials compared to classic wood, the cost of maintenance and living is significantly lower. Insurance costs are generally cheaper for ICF buildings due to their increased strength and fire resistance. Building owners will end up saying roughly 20% more on energy costs by building with ICF compared to wood.

Assuming a 100-year service life of a building, a single ICF home has the potential to save roughly 110 tons of CO2 which more than offsets the CO2 associated with the production of the cement used to make the concrete and can contribute to a company’s efforts to become carbon neutral or carbon negative.

At a time when climate change is at the forefront of everyone’s mind, it is more important than ever to ensure that we are collectively working towards minimizing our carbon footprint. To achieve this goal, we can replace outdated building materials like wood with modern insulative concrete foams. This change will enable both homeowners and larger building developers to contribute in mediating negative environmental impacts and reducing CO2 emissions.

Author: Kallista Wilson | Junior Technical Writer | Thermtest

Does A Brick Home Need Insulation? | Brick Siding. (2020, March 20). Modern Design. https://gambrick.com/does-a-brick-home-need-insulation/

Insulated Concrete Forms—Energy Performance and R-Values. (n.d.). Insulated Concrete Forms ICFs by Quad-Lock. Retrieved May 26, 2021, from https://www.quadlock.com/insulated-concrete-forms/ICF_energy_performance.htm

Insulating Concrete Forms (ICFs). (n.d.). Retrieved May 26, 2021, from https://www.cement.org/cement-concrete/paving/buildings-structures/concrete-homes/building-systems-for-every-need/insulating-concrete-forms-(ICFs)

Jul 14, Resistance, 2020 | Disaster, Efficiency, E., Stories, F., Costs, I. C. F., & ICFs?, W. (n.d.). Benefits of Living in an ICF Home | ICF Builder Magazine. Retrieved May 26, 2021, from https://www.icfmag.com/2020/07/benefits-of-living-in-an-icf-home/