May 6, 2024

The Laser Flash Method has revolutionized the field of thermal conductivity measurement. Invented in 1961 by W. J. Parker and colleagues, this innovative technique offers a rapid, accurate, and non-destructive way to determine a material’s thermal conductivity, thermal diffusivity, and specific heat capacity. Let’s dive into the working principles, historical significance, practical applications, and limitations of the Laser Flash Method, providing a comprehensive understanding of this valuable tool.

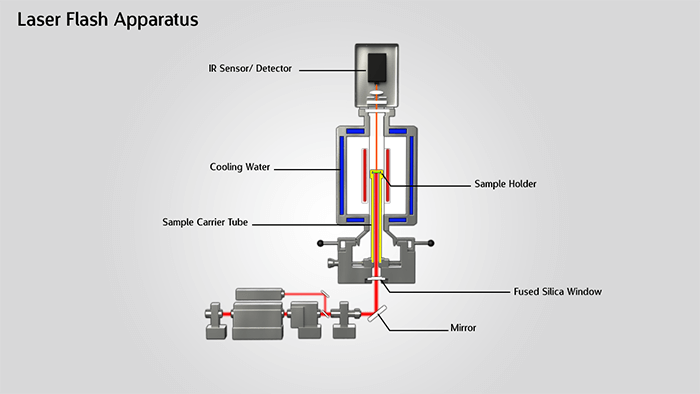

At the heart of the Laser Flash Method lies a precisely controlled laser pulse. The optical fiber laser beam acts as a light pulse to supply an energy source that is absorbed in the front of the testing material while the temperature is measured in the back by a thermocouple and recorded using an oscilloscope. This high-intensity laser beam heats the front surface of a disc-shaped sample, generating a transient temperature rise. A thermocouple positioned on the opposite side of the sample detects the subsequent temperature change over time. This temperature rise profile, captured with high precision, reveals crucial information about the material’s thermal properties.

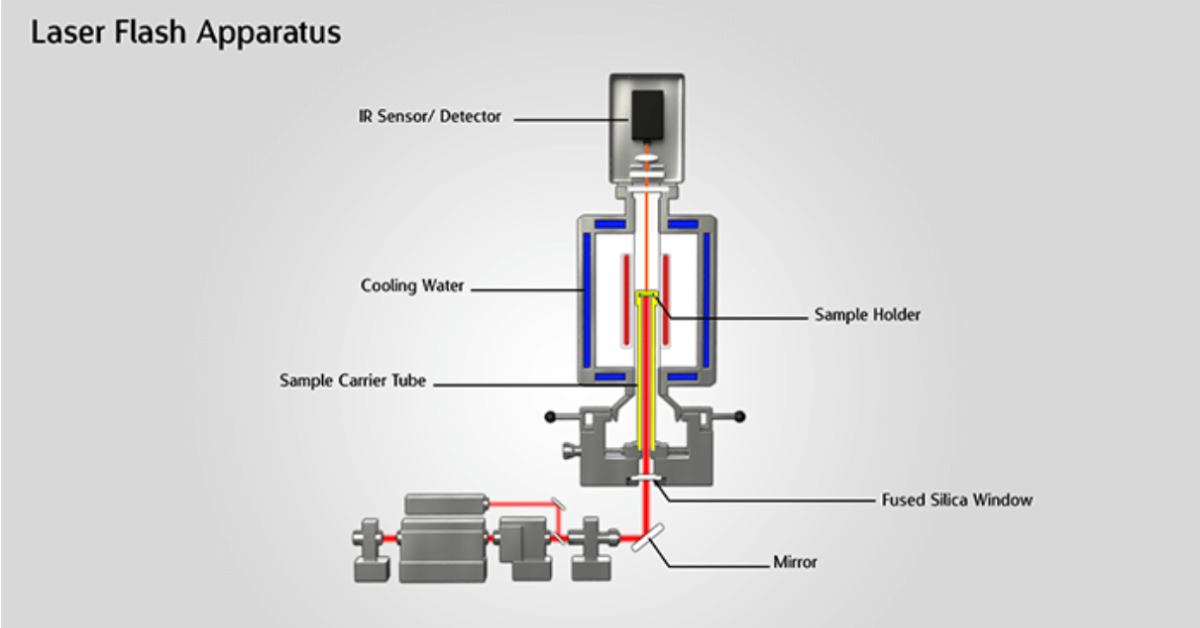

Figure 1. Schematic diagram of the Laser Flash Apparatus

The testing temperature range varies depending on the specific apparatus, typically from -125°C to a reported 2800°C – range of 0.1 to 2000 W/mK. Modern Laser Flash systems utilize advanced software and algorithms to analyze temperature data and accurately calculate thermal diffusivity.

Figure 2. Laser pulsation through sample material

Imagine a thin disc-shaped sample placed within a chamber. A powerful laser beam strikes the front surface, causing a localized and rapid temperature increase. A highly sensitive thermocouple on the opposite side continuously monitors the temperature change, providing a real-time record of the heat diffusion through the sample.

Before the Laser Flash Method, thermal conductivity measurement relied on techniques like the steady-state method, which involved establishing a constant temperature difference across a sample and measuring the heat flow. While accurate, this method was time-consuming and required specific sample configurations.

The Laser Flash Method transformed the field by introducing a transient approach. By analyzing the rapid temperature rise within the sample after a short laser pulse, researchers gained a more efficient and versatile method for determining thermal properties. This innovation significantly improved the speed and accessibility of thermal conductivity measurements.

Unlike other methods on the market, Laser Flash cannot measure thermal conductivity directly without calibration. It is determined by the shape of the temperature versus time curve at the rear surface. A simple formula can calculate thermal conductivity using thermal diffusivity (a), specific heat capacity (Cp), and density (ρ) as a function of temperature.

Λ(T)= a(T) • Cp(T) • ρ(T)

As with most methods, some testing conditions are needed to obtain accurate values. Laser Flash has sample limitations and complexity associated with using the instrument for measurements. The high temperatures are useful for ceramic and aerospace testing but are limited to a small range of homogeneous materials.

Although the Laser Flash Method provides considerable benefits, it is also vital to consider some limitations, including:

Figure 3. Understanding polymers is critical to optimize their performance in your application.

Despite these limitations, the Laser Flash Method remains a preferred technique for measuring the thermal properties of a wide range of materials, including:

The aerospace industry relies heavily on materials with precisely defined thermal properties to ensure aircraft and spacecraft’s structural integrity, performance, and safety. These vehicles operate under extreme conditions, experiencing wide temperature fluctuations and demanding thermal management solutions.

Figure 4. Space shuttle preparing to launch.

The Laser Flash Method has become an indispensable tool for aerospace engineers due to its ability to accurately characterize the thermal conductivity of a wide range of materials used in critical components:

By providing accurate thermal conductivity data for these critical materials, the Laser Flash Method empowers aerospace engineers to:

The Laser Flash Method has become an invaluable asset in the aerospace industry, contributing significantly to the development of safe, reliable, high-performance aircraft and spacecraft.

The Laser Flash Method has established itself as a cornerstone in thermal conductivity measurement. Its rapid, accurate, and non-destructive nature has revolutionized how researchers and engineers characterize the thermal properties of diverse materials. As technology advances, further refinements and automation of the Laser Flash Method can be expected, further solidifying its position as an indispensable tool for thermal analysis in various scientific and industrial applications.

Sources

W. J. Parker, R. J. Jenkins, C. P. Butler and G. L. Abbott, Flash Method of Determining Thermal Diffusivity, Heat Capacity, and Thermal Conductivity, J. Appl. Phys. 32, (1961) 1679

T. Baba, A. Ono, Improvement of the Laser Flash Method to Reduce Uncertainty in Thermal Diffusivity Measurements, Measurement Science and Technology, 12, (2001)