Where do the terms hardwood and softwood come from, you might ask? The common assumption has to do with density; the hardwoods have a higher density and are therefore more durable, and vice versa. In actuality, the name stems from the origin of the plant. Hardwood trees sprout from enclosed seeds, referred to as angiosperms, whereas softwood trees grown from uncovered seeds, gymnosperms, which germinate when blown around. Alongside the difference in origin, a variation in the structure of the two wood types is also present. Softwoods tend to have long, linear tubes for the transportation of water and stem strength, whereas hardwoods have pores. Hardwoods, such as oak and maple, tend to be used for applications such as deck boards and hardwood floors, while softwoods, such as fur, pine and spruce, tend to be used for lumber and decorative pieces.

Figure 1. Pine is used for an assortment of applications ranging from studs and trusses for home construction (left)1, to flooring and trim finishes for the inside of the home (right)2.

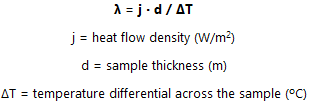

In this experiment, researchers at Thermtest set out to measure the thermal conductivity (W/m·K) of a pine disk at 20˚C using the Heat Flow Meter (HFM). The HFM has the capability of measuring the thermal conductivity and thermal resistivity of flat slab insulating materials such as foams, solids and textiles, by means of a steady state technique. The HFM measures the heat transfer properties of materials ranging in thermal conductivities from 0.005 to 0.5 W/m·K. The Heat Flow Meter can also simulate real world environmental temperatures, spanning from a cool -20°C and to a scorching 70°C, in accordance with ASTM C518-15 – Standard Test Method for Steady-State Thermal Transfer Properties by Means of the Heat Flow Meter Apparatus.

Figure 2. The Thermtest Heat Flow Meter (right), is a steady-state heat transfer system measuring the thermal conductivity and thermal resistivity of flat slab insulating materials, such as pine (left), from a single measurement.

To begin, a standard measurement was performed on a similar sized specimen of NIST SRM 1450d. Next, the pine sample (18.9 mm) was placed within the HFM and the standard measurement was loaded into the software. The parallel plates were then set to automatically adjust to the height of the specimen. The auto adjustment method employs the use of four digital encoders, one in each corner of the upper plate, which perform sample thickness measurements at their individual locations. An average of those thickness readings is then calculated and the upper plate is set to compress onto the specimen to the average thickness.

The two parallel plates, one on either side of the specimen, establish a steady state one-dimensional heat flux through the pine disk, at constant but distinct temperatures (ex: 10 ºC and 30 ºC). A temperature gradient, such as this, is set to mimic the heat loss from the interior to the exterior environment of a home. Although the size of the HFM chamber can accommodate for a sample as large as 12” X 12” X 4”, the heat flux transducers are positioned in the center of the upper and lower plates, allowing for any sample shape and a size as small as 6” X 6” X 0.4”. By appropriate calibration of the heat flux transducer(s) with standards, and by measuring the plate temperatures and plate separation, Fourier’s law of heat conduction is used to calculate thermal conductivity (λ):

A thermal conductivity of 0.1213 W/mK, for pine was the product of the HFM measurement. Presently, wood has become an alternative to brick in the construction of homes. This change in construction material can be attributed to the thermal conductivity of softwoods being approximately 1/7 that of brick. Thanks to a lower thermal conductivity of the wall materials, heat loss from the inside out is minimized during cold weather, and heating costs are ultimately lowered.

When using the HFM, users can expect a degree of accuracy better than 3% and a repeatability within 0.5%. The results received match the suggested thermal conductivity of softwoods, of 0.12 W/mK, confirming the high accuracy of this instrument. The Thermtest Heat Flow Meter is a simple, rapid and accurate method for measuring the thermal conductivity of materials from a single, steady state measurement.

The Thermtest Heat Flow Meter (HFM) provides users with the ability to measure thermal properties of larger, flat slab specimens ranging in thermal conductivities from 0.005 to 0.5 W/m∙K. The Heat Flow Meter is capable of measuring the steady-state heat transfer properties of foams, solids, and textiles.

References:

Image References: