The ability to accurately measure the thermal conductivity of materials is crucial to determining applications for which their properties are ideally suited. There are a variety of ways that thermal conductivity of ceramic testing can be completed, however not all methods are created equal. The accuracy of each method is an important deciding factor, in addition to more practical considerations such as the measurement length and ease of test set up.

Thermtest’s portable measurement system, the TLS-100 (Figure 1), performs thermal conductivity and resistivity testing on soils, solids, and powders over a range of 0.1 to 5 W/mK. Measurements are performed in accordance with ASTM Standard D5334, and have a reproducibility of 2% and an accuracy of 5%. This equipment is an excellent, convenient choice for use in the lab and the field, and can perform in temperatures ranging from -40 to 100°C. In this application page we will showcase the ability of the Thermtest TLS-100 to test the thermal conductivity of ceramic steatite and bisque fired alumina, two important materials in industrial applications.

Figure 1. The Thermtest TLS-100 is a powerful thermal conductivity meter testing tool in a convenient, portable package.

Steatite, also known as soapstone, is highly prized for its heat resistant, insulating properties. It is used extensively in electrical panels, wood stove construction, countertops, and as molds for molten metal due to its ability to absorb and slowly release the heat that it is exposed to without becoming unstable or deteriorating. The physical properties of this material can vary between different quarries as a result of different mineral compositions and pressure and temperature conditions during formation. Like steatite, bisque fired alumina is used in aerospace, automotive, and large scale industrial applications due to its insulating properties at high temperatures. It is a material that can be easily shaped and machined, and therefore is a convenient choice.

Figure 2. Photo of steatite moulds used to create metal objects. Steatite is excellent for use as moulds as it has highly heat resistant properties. 1

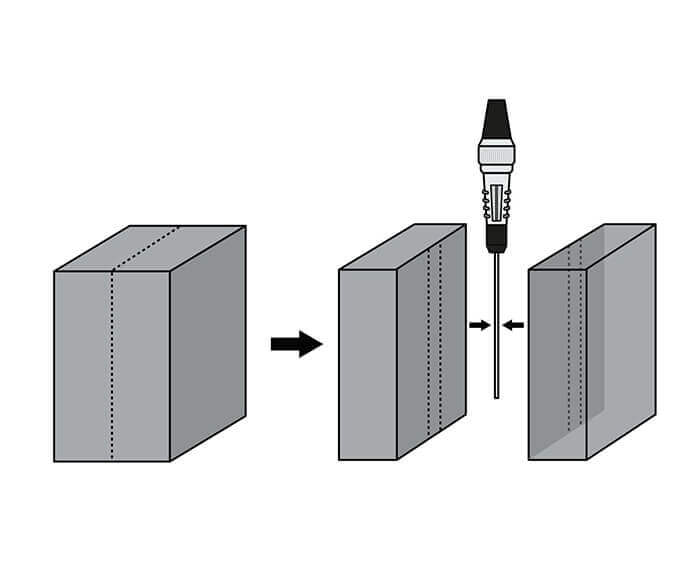

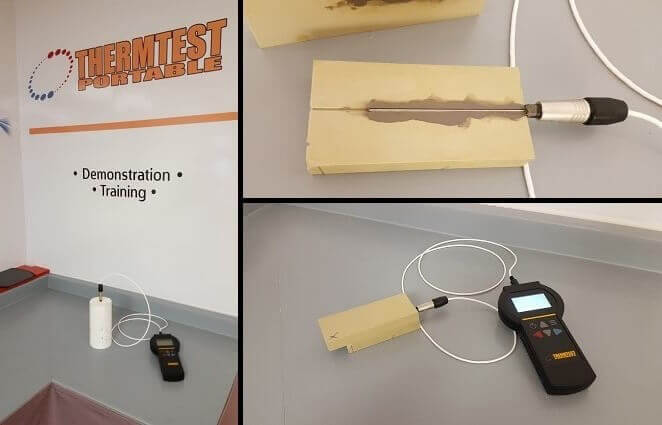

The TLS-100 operates through the insertion of a needle probe into the sample, and takes measurements over a set time period as the sample is heated and left to cool. This set up results in minimal damage to the sample due to the test. For this specific testing, Thermtest scientists cut samples of bisque fired alumina and steatite in two. The TLS-100 needle probe was coated in a thin layer of thermal paste, and the two pieces of each sample were sandwiched around the probe, ensuring excellent thermal contact (Figures 3 and 4). A total of five measurements with 120 second test times were taken for each sample. The TLS-100 measures both the thermal conductivity and thermal resistivity simultaneously.

Figure 3. Diagram illustrating the method used to sandwich the needle sensor of the TLS-100 between the two sample pieces of bisque fired alumina and steatite.

Figure 4. Photos displaying the test set up used to measure the thermal conductivity of ceramic steatite and bisque fired alumina in the Thermtest lab.

The thermal conductivity and thermal resistivity values measured by the TLS-100 are listed in Table 1. An average thermal conductivity of 5.077 W/mK was obtained for bisque fired alumina, which is exactly within the accepted thermal conductivity range of 5 to 5.25 W/mK for this material. The value of 3.107 W/mK produced for the steatite sample also corresponds well with reference materials that provide 3 W/mK as the thermal conductivity for steatite.

Table 1. Thermal Conductivity of Ceramic: Thermal conductivity and thermal resistivity of steatite and bisque fired alumina obtained using the TLS-100 in the Thermtest Lab.

| Bisque Fired Alumina | Steatite | ||||

| Test # | Thermal Conductivity (W/mk) | Thermal Resistivity (mK/W) | Test # | Thermal Conductivity (W/mK) | Thermal Resistivity (mK/W) |

| 1 | 5.005 | 0.199 | 1 | 3.098 | 0.322 |

| 2 | 4.953 | 0.201 | 2 | 3.076 | 0.325 |

| 3 | 5.137 | 0.194 | 3 | 3.203 | 0.312 |

| 4 | 5.181 | 0.192 | 4 | 3.085 | 0.324 |

| 5 | 5.108 | 0.195 | 5 | 3.075 | 0.325 |

| Mean | 5.077 | 0.196 | Mean | 3.107 | 0.322 |

These tests showcase the ability of the Thermtest TLS-100 to measure the thermal conductivity of ceramic quickly and accurately, with minimal damage to the sample itself. When searching for equipment to fulfill thermal conductivity measurement needs, the TLS-100 is an excellent choice that can be utilized in both the lab and the field on a wide variety of samples.

Thermtest’s TLS-100 presents field researchers the opportunity to measure the thermal properties of organic materials, such as soils and concrete. This instrument relies on the Transient Line Source (TLS) technique to provide efficient and accurate thermal conductivity readings of soils, powders and solids, ranging in thermal conductivities of 0.1 to 5 W/mK.

References: