Efficient heat dissipation is crucial for preventing overheating, ensuring optimal performance, reliability, and longevity of electronic devices. Thermal Interface Materials (TIMs) enhance heat transfer between components. Improving their overall thermal conductivity helps to remove heat from sensitive components like processors, semiconductors, and power modules.

The following case study is presented to emphasize the importance of understanding and obtaining accurate thermal conductivity measurements for TIMs in electronic applications. Along with highlighting common challenges faced with these measurement techniques and our proposed solutions.

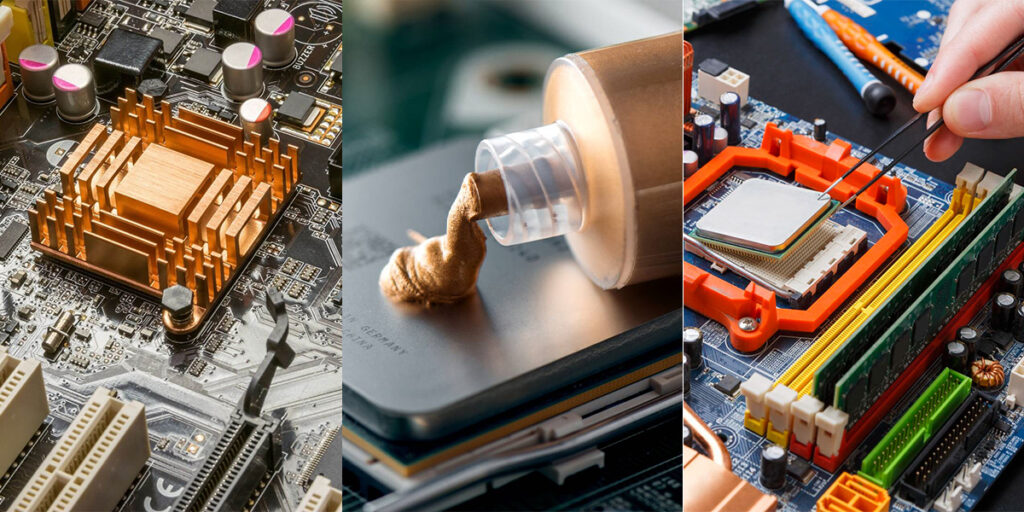

Figure 1. Common types of TIMs used in electronics.

Thermal management in electronics can often face several challenges such as increasing power density. As electronics become more powerful and more compact in design, they generate more heat in smaller areas making it harder to manage temperature efficiently. Excessive heat build up may lead to overheating causing components to degrade or malfunction which impacts the devices’ reliability, lifespan, and overall performance.

Effective thermal management is crucial in maintaining energy efficiency. Poor heat dissipation can reduce the overall device performance, as heat can increase resistance and power consumption. This can also lead to performance throttling, where devices intentionally reduce their operating speed to try and prevent overheating.

Inadequate cooling can lead to failure and even permanent damage of electronic components. Effective thermal management solutions like heat sinks, active cooling, and TIMs, are critical to addressing these challenges and ensuring reliable, long lasting, and high-performance electronics.

Manufacturers of TIMs rely on accurate thermal conductivity measurements to develop products that meet market demands and performance standards. Similarly, users of TIMs depend on precise thermal conductivity data for validation purposes, both in experimental testing and simulation modeling, ensuring optimal performance and reliability in their applications.

The wide variety of thermal conductivity testing methods is compounded by a lack of comprehensive international standards to validate their suitability for specific applications. Selecting an appropriate method can be a complex and daunting task, with the potential for long-term negative impacts on project outcomes if the wrong choice is made.

Manufacturers of TIMs require accurate measurements of thermal conductivity for use in development of materials. Through the engineering process, stages of improvement can be realized. Completion of a project can result in launch of a material that meets market demand based on reliable trust-worthy results.

Users of TIMs require accurate measurements of thermal conductivity for validating available TIMs on the market. This engineering process involves internal measurements of thermal conductivity to compare against specifications determined by the simulation process.

There are several types of TIMs used in electronics, each with their own characteristics, and various methods to measure their thermal conductivity. These include thermal pads, adhesives, gels, epoxies, liquid metals, heat spreaders, grease/paste, and gap fillers. With test methods from transient to steady state.

Our innovative philosophy and unique range of thermal conductivity methods, ensures every customer is matched with the perfect instrument to meet their current and future needs. Thermtest manufacturers a wide range of thermal conductivity methods and stays involved in the international standards (ASTM & ISO) governing bodies to ensure we are offering the most appropriate method for the application.

Figure 2. Measurement Platform – Transient Plane Source (TPS) for thermal conductivity, thermal diffusivity and specific heat of following ISO 22007-2.

The Measurement Platform (MP series) offers a growth-minded range of methods designed to scale with performance, meeting increasingly demanding applications. The MP series provides multiple, accurate thermophysical testing methods for solids, pastes, and powders, with intelligent design that automate testing while offering raw data for expert analysis.

Several patented technologies to improve your testing capabilities, offering evolved TPS method. Such as, iTransient™, fully automates parameter selection and analysis. The intelligent TPS only requires input of sample name and dimensions. This technology selects sensor size, power and test time, while analyzing results in compliance with ISO standards. Manual parameter selection and analysis is available for deeper understanding, when needed.

To highlight the powerful capabilities and accuracy of the MP series for measuring TIMs such as gap fillers, Themtest’s Advanced Measurement Platform (MP-1) was used to measure PG45A a putty sheet type gap filler from Fujipoly. A summary of the results can be found below. The results were found to be within 2% of the theoretical thermal conductivity stated on the materials catalog (4.5 W/m·K).

| Temperature (°C) | Thermal Conductivity (W/m·K) |

| 22.9 | 4.661 |

| 4.615 | |

| 4.647 | |

| 4.651 | |

| 4.608 | |

| Mean | 4.637 |

| St. Dev. | 0.023 |

| RSD % | 0.5 |

The thermal conductivity of TIMs is one of the most important properties for such materials, as it directly influences the performance and longevity of devices such as processors, power transistors, and high-performance computing systems. Different applications have different thermal management needs, and the optimal TIM properties may vary depending on the use case. Materials with high thermal conductivity, such as metal or graphite based TIMs, are preferred for systems where prolonged heat dissipation is required. For systems where space and weight are constraints, thermally conductive pads or phase-change materials might be chosen to balance performance and form factor.

Thermtest’s MP-1 with TPS method was proven to provide accurate results within 2% of the stated value. This allows manufactures and users alike to have high confidence and understanding of the measured value for their products which correlates with device performance outcomes including efficiency, stability, and reliability.

Thermtest instruments help optimize thermal management by accurately measuring the thermal properties of TIMs, such as thermal grease and paste, within 3% or less. This precision enables more authentic simulations, higher power densities, and miniaturization of devices. Which leads to improved reliability, efficiency, and performance in modern electronics.

The electronics industry requires international collaboration to create unified testing standards for TIMs to ensure consistency and reliability in thermal measurements across global markets. Future research will focus on exploring advanced TIM compositions and their thermal properties. Additionally, ongoing development of measurement techniques, like the future-proof MP series, is crucial to meet evolving industry demands.

Accurate thermal conductivity measurements are vital for the performance and reliability of Thermal Interface Materials (TIMs) used in electronics. These measurements help in ensuring proper heat dissipation, preventing overheating, and maintaining device performance and longevity.

The MP series is one of many solutions Thermtest provides to future-proof testing for addressing current challenges in TIM applications. Thermtest’s MP series offers accurate, scalable testing methods, incorporating advanced technologies that automate parameter selection and analysis, aligning with ISO standards.

It is essential to select the proper testing methods for TIMs to optimize thermal management in electronics. Using accurate measurements ensures the correct validation of TIMs, improving device efficiency, stability, and performance. Future research and the development of standardized testing methods will be crucial to advancing the field and addressing evolving industry needs.

Fujipoly. (n.d.). PG45A thermal gap filler pads/putty. Fujipoly. Retrieved February 21, 2025, from https://www.fujipoly.com/usa/products/sarcon-thermal-management-components/thermal-gap-filler-products/gap-filler-pads-putty/pg45a.html