September 25, 2020

How thermal effusivity and additional thermal properties quantifies the touch/feel of automotive interiors

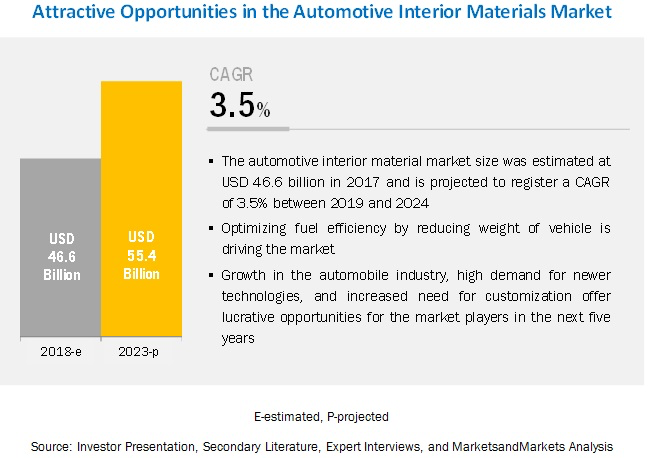

The global automotive interior industry is one of increasing importance and has continued display steady growth patterns throughout the past decade. The appropriate selection of an interior material is gaining significance as consumer market continues to prioritize increasing the fuel efficiency of a vehicle and a desire to decrease the harmful impacts that the automotive industry is known for inflicting on the environment. The global automotive interior market was valued at 46.63 billion USD in 2018 and is predicted to reach 55.41 billion USD in 2023. This growth is driven by a need for optimizing fuel efficiency by decreasing the weight of interior materials while also increasing their thermal insulation capabilities.

Figure 1: Estimated and predicted value of the Global Automotive Interior industry.

Source: www.marketsandmarkets.com

Most automotive interiors are composed of a variety of materials including but not limited to, leather, nylon, vinyl chloride, faux leather, or polymers. Synthetic polymers are currently the most widely used material because they are extremely lightweight and durable. The use of genuine leather is decreasing globally as the harmful environmental impacts cause during leather processes are continuing to become more public knowledge. Leather is also one of the most expensive materials on the market and offers little advantage in terms of comfort and thermal insulation.

Recent technologies are researching the impacts of incorporating and combining different thermal materials within a vehicle’s interior to minimize energy loss. The use of synthetic materials to mimic environmentally harmful materials, such as replacing authentic leather with synthetic leather, can benefit the consumer in multiple ways. Choosing these alternative materials can increase thermal comfort and fuel efficiency and are more sustainable for manufacturers to produce. One method being used to maximize efficiency is incorporating nanoparticles into different foams and plastic to achieve more desirable thermal properties.

The materials used for car interiors extends beyond what is used for the seats. The same material is often used for the steering wheel, arm rests and handles. An interior material is selected with an aim to reduce the power needed for generation and displacement of hot/cold air within the car. Vehicle heating and cooling exerts a large power demand on a car battery and engine which leads to increased carbon emissions and fuel consumption. Impacts of selecting an efficient material include increased fuel efficiency, passenger safety, range, reliability, and overall comfort. A secondary impact of improving the driver’s comfort is increased alertness and generally a more enjoyable driving experience.

Figure 2: Interior view of a luxury car with a leather seats and additional interior aspects

Different materials are characterized by their thermal properties and how these properties are reflected on the overall comfort of the driver in a range of conditions. An ideal interior material has a low thermal conductivity and a high thermal resistance. Thermal resistance describes a materials ability to restrict the flow of heat through it and is a common property of many insulation materials such as cotton and foam. Thermal resistance is the reciprocal of thermal conductivity which describes a materials ability to effectively transfer heat.

A material with a high thermal conductivity will exhibit a low thermal resistance. The thermal property that relates to the touch and feel of a material is known as it’s thermal effusivity. This property is characterized by a materials heat storing or dissipating abilities. Thermal effusivity is the mechanism that explains why metal feels colder to touch than wood even when these objects are kept in an environment at the same temperature. The heat transfer occurring from the skin to the metal is much faster compared to the transfer that occurs between skin and wood.

Thermal effusivity is equal to the square root of the product of thermal conductivity and the materials heat capacity. A material with a high thermal conductivity will also exhibit a high thermal effusivity. For example, the thermal conductivity of silver is measured at 406 W/(m/K) and displays a thermal effusivity of 32520 W√s/m2K. The correlation between these thermal properties is evident when comparing these values to that of wood. Wood has an average thermal conductivity of 0.194 W/(m/K) and a thermal effusivity of 526 W√s/m2K. The difference in these thermal values also explains why wood has a higher thermal resistance. Automotive interior materials such as foam and polymers exhibit similar thermal properties to wood and are frequently selected during vehicle design based on their energy saving capabilities from having a low thermal conductivity and effusivity.

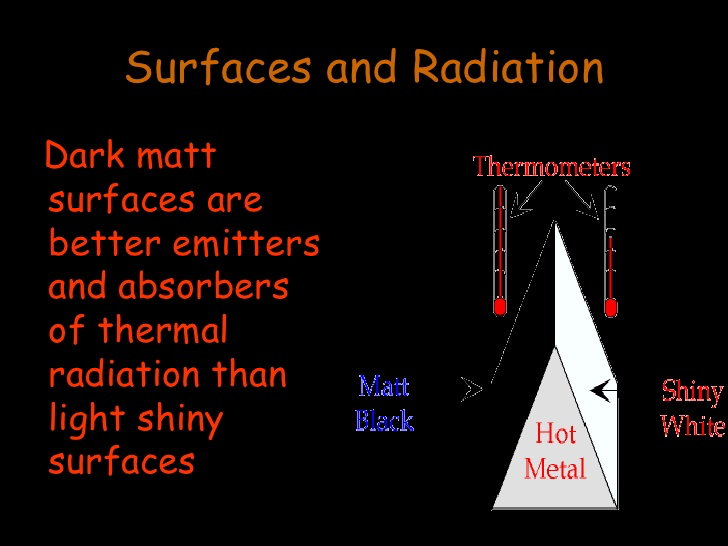

Additional factors such as material quality, touch, colour and texture all need to be considered when selecting a functional fabric upholstery to use for an automotive interior. Some of these factors also impact a materials emissivity. Thermal emissivity is classified as the amount of thermal radiation that an object emits. This property is classified on a scale from 0-1 with 1 being referred to as “the black point”. A material with a clean/smooth surface generally has a low emissivity compared to material with a rough surface having a high emissivity.

Materials with a high thermal emissivity are quick to lose heat to their surroundings compared to materials with a lower value that store more heat and limit the amount lost in the form of infrared radiation. This thermal phenomenon explains why black leather seats feel extremely warm after sitting in the hot sun. The colour and texture of the seat material influences the amount of radiation emitted and creates a warm (sometimes too hot) surrounding environment.

Figure 3: Example of the thermal emissivity behavior of different materials

Figure 3: Example of the thermal emissivity behavior of different materials

The importance of selecting an appropriate automotive interior material is continuing to become of increasing importance as automotive companies continue to design and research new technologies that will be more sustainable. The main idea behind this focused market is to reduce the amount of energy and fuel required for the generation and displacement of hot and cold air. This goal can be achieved by maximizing the efficiency of a material with energy saving properties. Other components that consumers should take into consideration include environmental impacts, cost and durability. A major characteristic of fabric upholstery that impacts the overall performance of a material are its thermal properties. These properties include thermal conductivity, effusivity, resistance and emissivity.

Fabrics that are foam or polymer-based exhibit low thermal conductivities and effusivity making them an ideal material to use for an automotive interior. Other materials such as leather and polyvinyl chloride have less desirable thermal properties and are also more expensive and environmentally harmful to produce. Additional factors such as material colour and texture should be considered when selecting a material in order to minimize energy waste and the amount of strain put on a car engine. At the end of the day, it is the consumers priorities that will influence the type of material they select, however, it is still important to consider factors beyond what is most aesthetically pleasing when selecting an upholstery fabric that will benefit the driver in a number of ways.

Marshall, G.J., Mahony, C.P., Rhodes, M.J., Danielwicz, S.R., Tsolas, N., Thompson, S.M. 2019. Thermal management of vehicles cabins, external surfaces, and onboard electronics: an overview. Engineering. 5(5): 954-969. https://doi.org/10.1016/j.eng.2019.02.009

Dante, R.C. 2016. Handbook of fricton metals and their applications. Metals. 9: 123-134. https://doi.org/10.1016/B978-0-08-100619-1.00009-2

Houngan, C.A., Awanto, C., Djossou, A., Anjorin, M., Vianou, A. 2015. Measurement of thermal effusivity of thermal conductivity at various water content for two tropical wood species. Procedia Engineering. 127: 48-55. doi:10.1016/j.proeng.2015.11.328

Automotive Interior Materials Market. (n.d.). Retrieved from https://www.marketsandmarkets.com/Market-Reports/automotive-interior-materials-advanced-technologies-and-global-market-89.html

Author: Kallista Wilson | Junior Technical Writer | Thermtest