November 21, 2022

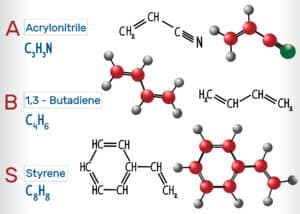

This blog is about the thermal properties and general applications of acrylonitrile-butadiene-styrene, also known as ABS. ABS is an amorphous, impact-resistant thermoplastic polymer. It is composed of three monomers: acrylonitrile, butadiene and styrene. Acrylonitrile is a synthetic monomer derived from propylene and ammonia. This component helps improve the chemical resistance and thermal stability of ABS. Butadiene is produced as a by-product of ethylene production in steam crackers. This component gives the ABS polymer its hardness and impact resistance. The dehydrogenation of ethylbenzene produces styrene. It provides rigidity and processability. ABS falls between standard resins and engineering resins and usually meets the demand for performance at a reasonable price-to-cost ratio. ABS is primarily polymerized via an emulsification process or by hand from various products that are generally not combined into a single product.

The acrylonitrile in ABS is chemically and thermally stable, while butadiene provides hardness and strength. The styrene gives the finished polymer a nice glossy finish, and ABS has a low melting point, which facilitates its use in injection moulding and 3D printing. It also has high tensile strength and is resistant to physical and chemical attacks, making the finished plastic withstand heavy use and harsh environmental conditions. ABS can be moulded, sanded and shaped, and its glossy surface is highly compatible with a wide range of coatings and adhesives.

Polymers are an integral part of everyday life, and more research is being conducted daily to develop new, more versatile and novel polymers. Testing these polymers’ thermal conductivity is paramount to determining their thermal performance under different conditions. There are two different methods to test polymers.

The Transient Plane Source (TPS) provides a fast and accurate measurement of polymers’ thermal conductivity under various environmental conditions. Transient Line Source (TLS) can measure the thermal conductivity of molten polymers. The thermal conductivity of common unfilled plastics, such as ABS, Nylon and Delrin is shown below.

| Type of unfilled plastic | Thermal Conductivity |

| Acrylonitrile-butadiene-styrene (ABS) | 0.14-0.21 W/m·K |

| Acetal (Delrin) | 0.23-0.36 W/m·K |

| Cellulose acetate (CA) | 0.16-0.36 W/m·K |

| Diallyl phthalate (Dajon) | 0.31 W/m·K |

| Epoxy | 0.19 W/m·K |

| Ethylcellulose | 0.23 W/m·K |

| Ethylvinylacetate | 0.08 W/m·K |

| Phenolic | 0.17 W/m·K |

| Polyamide (Nylon 6-11-12-66) | 0.24-0.3 W/m·K |

| Polyaramide (Kevlar, Nomex fibers) | 0.04-0.13 W/m·K |

| Polycarbonate (PC) | 0.19-0.22 W/m·K |

| Polytetrafluorethylene (PTFE, Teflon) | 0.25 W/m·K |

| Polyethylene terephthalate (PET, Polyester) | 0.15-0.4 W/m·K |

| Polyethylene L (Low Density) | 0.33 W/m·K |

| Polyethylene HD (High Density) | 0.45-0.52 W/m·K |

| Polyimide (Kapton) | 0.10-0.35 W/m·K |

| Polymethylmethacrylate (PMMA, Acrylic, Perspex, Plexiglass) | 0.17-0.19 W/m·K |

| Polyphenylene oxide (PPO, Noryl) | 0.22 W/m·K |

| Polypropylene (PP) | 0.1-0.22 W/m·K |

| Polystyrene (PS) | 0.1-0.13 W/m·K |

| Polysulfone | 0.26 W/m·K |

| Polyurethane (PUR) | 0.29 W/m·K |

| Polyvinylchloride (PVC) | 0.12-0.25 W/m·K |

| Polyvinylidene fluoride (Kynan) | 0.1-0.25 W/m·K |

Figure 1: All values in the table are defined at room temperature.

Adreco plastics. “ABS Plastic Properties.” Adreco Plastics, 9 July 2021, https://adrecoplastics.co.uk/abs-plastic-properties/.

Lasance, Clemens J. M. “The Thermal Conductivity of Unfilled Plastics.” Electronics Cooling, 2 July 2019, https://www.electronics-cooling.com/2001/05/the-thermal-conductivity-of-unfilled-plastics/.

Omnexus. “Thermal Insulation.” Thermal Insulation of Plastics: Technical Properties, https://omnexus.specialchem.com/polymer-properties/properties/thermal-insulation.

Professional Plastics. “Thermal Properties of Plastic Materials.” Professional plastics, https://www.professionalplastics.com/.

Tomasz G. Comprehensive Guide on Acrylonitrile Butadiene Styrene (ABS) – Specialchem. Aug. 2021, https://omnexus.specialchem.com/selection-guide/acrylonitrile-butadiene-styrene-abs-plastic.