April 4, 2022

The task of designing proper thermal protective clothing is not one for the narrow-minded as several variables must first be taken into consideration in order to make a garment that will provide adequate protection for the person wearing it. When thermal stress is combined with overexposure to a harsh environmental condition, it can have a dramatic toll on the human body.

This is a concern that many professionals face daily while attempting to complete the duties associated with their high-risk jobs. Firefighters, first responders, astronauts, and combat officers are just a few examples of jobs that require a high level of thermal protective clothing to minimize the risks associated with their extreme working conditions. Thermal stress is experienced because of poor protective clothing design has been a serious issue for decades.

Recent statistics have revealed every year in the U.S, an average of 50% of firefighters’ deaths can be attributed to thermal stress. This can be experienced as either hot or cold stress, both of which can have devastating impacts on a person’s ability to maintain a consistent core temperature and metabolic rate. This heavy reliance on thermal protective clothing for relief from thermal stress has caused the demand for these specialized clothing items to soar.

The popularity of thermal protective clothing is pushed even higher as the frequency of hot and cold spells due to climate change puts additional strain on a person’s ability to maintain a stable core temperature. The pressure is now on researchers as they continue to search for and test novel material combinations that not only keep unwanted heat away from the wearer, but are also designed to provide more comfortable, breathable, and lightweight relief from all types of thermal stress.

Figure 1: Firefighters wearing protective clothing while performing their dangerous job.

The effectiveness of thermal protective clothing relies on the natural heat dispersing abilities of the materials it is made of. The majority of these materials possess a unique ability to defer heat away from the individual wearing them. This phenomenon is referred to as a material’s thermal resistance. A material with a high thermal resistance value will restrict the flow of heat through it and therefore provide a better protective barrier against overexposure to high temperatures. These highly insulative fabrics exacerbate thermal strain by limiting both heat and water vapor transfer.

The most common materials for making exceptional thermal protective clothing are coated fabrics which often include coatings made of neoprene, silicone, and ceramics. Silica fabrics and textiles are another category of heat resistant fabrics that have an astonishing continuous operating temperature of over 932°C. Their low thermal conductivity and high thermal resistance make them an ideal candidate for providing an extremely strong thermal protective barrier. Not only do these provide the wearer with excellent thermal protection, but they also shield them against abrasions, chemical spills, and harmful ultraviolet radiation. Most of the ambiguity surrounding the full degree of protection these materials deliver is centered around a researcher’s ability to measure the extent to which a certain material can act as an effective thermal barrier.

Figure 2: example of protective clothing that is required in a laboratory setting.

Researchers are currently investigating a number of new methods for measuring the level of protection provided by thermally resistive clothing using a variety of techniques and equipment. One of these methods uses a guarded hot plate to determine the thermal resistance and water permeability of a material. Thermal resistance can be measured as the reciprocal of thermal conductivity and describes the ability of a material to restrict the flow of heat through it. Just as electrical resistance is associated with the conduction of electricity, thermal resistance is associated with the conduction of heat.

That being said, materials with a high thermal conductivity will generally exhibit a low thermal resistance and vice versa. The majority of thermal resistance properties and values are reported using an R-value, with a higher R-value being indicative of a more effective insulation material. The main physical properties of a material that are reflected in its R-value include porosity, thickness, and density.

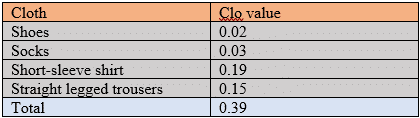

The insulation ability of clothing is measured slightly differently than the conventional method of determining the R-value. Certain articles of clothing are assigned a ‘Clo value’ which is a measure of their efficiency at passing heat through them. This value is obtained using the same methods as what is used to find the thermal conductivity or thermal resistance of a material with 1 Clo = 0.155 m2K/W. A Clo value of 0 is equivalent to someone wearing no clothing at all whereas a Clo value of 1 is representative of the insulation value required to keep an individual comfortable sitting at room temperature while performing no physical activity.

For thermal protective clothing, a Clo value greater than 1 is always required. The Clo value is obtained for any uniform or outfit by adding together all the Clo values from each individual article of clothing. For example, a person wearing socks, shorts, and a t-shirt would likely have a Clo value of roughly 0.4 with each item contributing a different degree to this overall total.

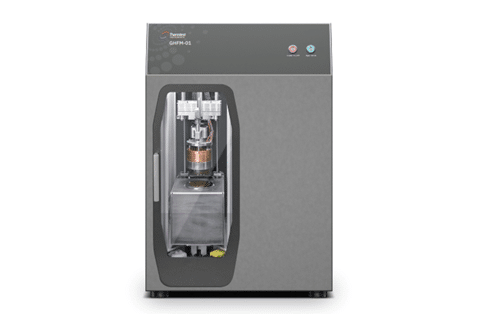

Guarded hot plate (GHP) testing is a popular method for describing and quantifying the biophysical properties of a material. This testing machine measures the dry and wet (evaporative) heat transfer through a single or multi-layered textile to provide insulation and permeability values. In order to determine these values, a patch sized sample of material is placed on a temperature controlled flat plate in a chamber that has tightly regulated environmental conditions. Measurements are then made according to a designated set of international standards and following specific quality control guidelines and protocols. This procedure is designed to mimic the heat transfer interactions that occur between a material and the body of the person wearing protective clothing.

These measurements not only need to consider the direct transfer of heat occurring between a person and the piece of clothing, but they also need to consider how the material interacts with the surrounding environment throughout a range of different weather conditions. Needless to say, the number of variables that must be considered in order to determine the full extent to which a material can provide a suitable level of protection can be extremely overwhelming for thermal engineers to incorporate into their selection of a proper material.

One major benefit of using a GHP is that it can quickly evaluate many different types of materials. Unfortunately, these measurements may not be entirely representative of how the textile measured as a 2D sample in a controlled environment will respond when it is used to construct an actual piece of clothing. Additions such as seams, buttons, and zippers can cause variations in a material’s thermal resistance and permeability values and therefore impact the level of protection that a piece of clothing may provide.

Figure 3: Thermtest’s guarded heat flow meter – ideal for measuring metals, polymers, composites, and pastes.

One way researchers have overcome some of the limitations associated with only using a 2D small patch of material, is by performing manikin testing trials. Using a manikin to mimic a more realistic situation can account for the influence of the individual wearing the item and the changes experienced by any additional equipment such as breathable body armor. When the manikin moves, researchers can measure the impact of airflow on the microclimate created by the thermal clothing as too much air movement can lead to a dramatic reduction in thermal insulation.

A couple of recent studies have attempted to use a manikin testing system to explore the effects of perspiration and shivering on the insulative ability of an article of thermal protective clothing. Excess evaporation, along with the heavyweight load these pieces of clothing inflict on the wearer can impact their comfort level and job performance severely if not accounted for during the designing process.

Figure 4: example of manikin testing for evaluating thermal protective clothing/textiles

The search for discovering new and improved insulation materials continues as testing companies explore new ways to harness the high thermal resistance values of specific textiles to design the most effective and safe thermal protective wear. The risks associated with poorly designed personal protective equipment are severe and the impact of thermal stress on the body can be life threatening. Therefore, it is extremely crucial for adequate tests to be performed on the materials used during the clothing design process so that first responders and professionals working to protect our communities can also be protected from the risks associated with their dangerous jobs.

Author: Kallista Wilson | Junior Research Scientist | Thermtest

Chapline, G., Rodriguez, A., Snapp, C., Pessin, M., Bauer, P., Steinetz, B., & Stevenson, C. (n.d.). Thermal Protection Systems. 18.

Clo—Clothing and Thermal Insulation. (n.d.). Retrieved February 5, 2022, from https://www.engineeringtoolbox.com/clo-clothing-thermal-insulation-d_732.html

Clothing | National Collaborating Centre for Environmental Health | NCCEH – CCSNE. (n.d.). Retrieved January 21, 2021, from https://ncceh.ca/content/clothing

Glossary of Terms and Definitions. (n.d.). Thermtest Inc. Retrieved December 21, 2020, from https://thermtest.com/thermal-resources/glossary

Pan, N. (2019). Unique Thermal Properties of Clothing Materials. Global Challenges, 3(7), 1800082. https://doi.org/10.1002/gch2.201800082