September 13, 2021

A brief introduction on the role of thermal conductivity during the design and application of heat treatment processes throughout food production and processing.

Humans are evolutionarily hardwired to crave sugary substances, and this need for sweets only grows stronger as we get older. When asked the extremely difficult question regarding their opinions on chocolate, most people will react with immediate excitement. Their responses will often detail how much they enjoy this sweet treat. Their faces will light up as they imagine the milky, smooth taste of their favorite chocolate bar and how they would love to acquire a piece of that sugary goodness as soon as possible. This love for chocolate and sweet products, in general, has fueled the success of the USA confectionery industry, which was valued at over USD 34.5 billion in 2020. The confectionary industry includes a wide range of delicacies consisting of cookies, chocolate, gummy bears, and even chewing gum. Unsurprisingly, chocolate sales account for over USD 21.1 billion of the confectionery industry, which equates to just over 60% of all confectionery sales. It’s safe to assume that society places a high value on the quality of these products that candy manufacturing companies produce. One major component that influences chocolate and candy production’s success is effective thermal regulation during processing.

Thermal processing is undoubtedly one of the most important aspects of the food production industry. The thermal processing concept is centered around heating foods for a predetermined period at a specific temperature. This processing application is designed to improve food products’ eating quality and safety by extending their shelf life and removing potentially harmful microorganisms. The textbook definitions of food heat treatment processes emphasize using different techniques, including blanching, cooking, drying, pasteurization, sterilization, and thawing. All of these processes share a heavy dependence on extensive knowledge surrounding the thermophysical properties of food. These properties primarily comprise of specific heat, thermal conductivity, thermal diffusivity, freezing point, and freezing range of a particular food product.

Figure 1: Food held in a freezer to maintain safety and quality standards.

The thermal conductivity of a material is just one of many thermophysical properties that must be accounted for during the design and application of thermal regulation in a food production line. Despite being one of many factors for manufacturers to consider, it is undeniably one of the most important food properties in terms of classifying and predetermining how a substance will respond when exposed to a high influx of heat. Thermal conductivity is described as the ability of a material to transfer heat through it effectively. Metals, such as silver or copper, exhibit extremely high thermal conductivity values due to their unique intermolecular arrangement that facilitates rapid heat transfer. Foam and wood are examples of low thermal conductivity substances and resist the flow of heat through them. These materials are commonly referred to as thermal insulators and are sought after for heat blocking applications. The thermal conductivity of a food product depends mainly on its chemical composition, molecular structure, and the temperature at which it is processed, however, mechanical production and measurement methods are also important to consider when determining the thermal conductivity of a substance.

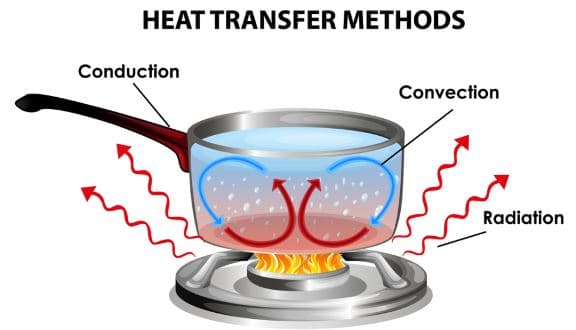

The success of thermal treatment on food products relies on how the product’s materials will respond to an influx in temperature. Heat transfer occurs in specially designed equipment that has been engineered to carry out the specific thermal treatment. Heat transfer in these machines occurs via three main mechanisms, which are conduction, radiation, and convection. Conduction can be described as the molecule to molecule or surface to surface transfer of kinetic energy. One molecule will become energized due to an influx of heat and transfer a portion of this energy to an adjacent molecule at a lower energy level. An example of heat transfer through conduction is when you cook an egg in a cast iron metal pan. The heat from the hot stove will transfer energy to the thermally conductive metal pan causing its molecules to become excited. These high-energy molecules are responsible for transferring the energy that will cook your egg. Conduction is used in the food processing industry to cook foods normally semi-solid in form and do not move (for example, if it’s stored in a can), such as pie filling or tomato paste.

Figure 2: Canned food products that would generally be heat treated with conduction mechanisms.

Convection refers to the transfer of heat through a fluid medium (such as air or water). When a fluid is heated, it travels away from the heat source due to a change in density, and as it moves, it carries thermal energy with it. The fluid located above the heat source will expand, become less dense and start to rise. The rising fluid will displace the even cooler, denser medium above it, forcing it to sink towards the heat source. The colder medium will come into contact with the heat sources where it warms, and the process occurs all over again. This constant feedback loop represents how convection currents are formed. Convection in canned foods occurs when the heating sets up currents in a liquid medium, for example, in a canned soup or juice.

Figure 3: Diagram depicting heat transfer mechanisms

Thermal radiation is generated through the emission of electromagnetic waves that carry energy away from an emitting object or thermal body. Our skin gives off heat and energy in the form of infrared radiation. To a degree, all materials radiate thermal energy based on their internal resting temperature. The hotter an object is naturally, the more heat it will radiate.

In food processing, production and packaging, normally, one or more of the above-mentioned heat transfer processes occur. The wall thickness of shipping containers is an important factor in preventing heat transfer or loss through conduction. The use of reflective surfaces such as aluminum when designing food packages can impact a product’s susceptibility to radiation. Any material that offers high resistance to heat transfer through conduction, radiation, or convection is declared to possess an insulator’s qualities and normally has an extremely low thermal conductivity. This heat resistance can be beneficial for restricting enzyme and microbe growth and poses a challenge to manufacturers when attempting to design adequate thermal treatment applications.

A large amount of food spoilage is a result of chemical reactions that involve microbes or enzymes. The speed of a chemical reaction is directly related to temperature, hence why lowering the surrounding temperature can slow down the rate of chemical spoiling. Refrigeration is one of the most common ways to perform this task as it provides a consistently cool and temperature-regulated environment for food products to be stored in. Most foods have their preferred humidity and temperature for safe storage; however, most modern refrigeration systems are held at 4 degrees Celsius. Freezing is another thermal process employed to preserve foods for a longer period than standard refrigeration.

Figure 4: foods that are especially susceptible to spoilage stored in a standard refrigerator.

Dairy is one of the most temperature-sensitive food products by far due to its susceptibility to spoilage and bacteria growth. Dairy products are thermally treated in a process known as pasteurization. Pasteurization involves the heating of milk or a milk product to a specific temperature for a specific period of time without allowing recontamination of that milk or product during the heat treatment process. This thermal application was designed to make dairy products safer for consumption by removing harmful bacteria and pathogens. Pasteurization can also improve the product’s quality by extending its self-life for up to two weeks compared to dairy products that haven’t been treated. To ensure the destruction of all pathogenic microorganisms, time and temperature combinations of the pasteurization process are highly regulated.

A significant component of using thermal processing techniques involves obtaining a balance between when a product is heated and what temperature it is heated at. Many different types of thermal equipment can help manufacturers determine these rates. One example is a thermal depth curve used to determine the cooking time and temperature needed to kill harmful microorganisms. The mechanical properties of the food itself can also have an impact on the heat-treatment process. Potential microorganisms, particle size, and food density are all important factors one should consider before heating a food product. The PH of a food is another factor that could influence the safety processes that may need to be employed during treatment. Microbes that have contaminated foods with a low PH (high acidity) can have extreme effects on a person’s digestive system, causing them to become extremely ill. High PH foods (low acidity) can contain microbes that can cause even more harm and may be fatal if ingested. These low acidity foods must be treated by methods that can bring the food to a higher temperature to ensure complete removal of toxic microorganisms.

Thermal conductivity is one of the unifying characteristics of a food product that can influence heat treatment success. Thermal conductivity relies heavily on the moisture content, temperature, and physical molecular arrangement of the material being treated.

Maintaining adequate thermal regulation for the production and transportation of temperature-sensitive goods is a primary concern to ensure the product isn’t spoiled before reaching the consumer. Food manufacturers constantly explore new thermal regulation methods that will deliver enough heat to kill a microorganism while still maintaining the food’s original qualities. Without extensive knowledge of thermophysical processes such as thermal conductivity, many of these heat treatments would not be successful, and the food industry would be impacted irreversibly.

Author: Kallista Wilson | Junior Technical Writer

Center, F. R. (n.d.). Chocolate Industry Analysis 2020—Cost & Trends. Franchisee Resource Center. Retrieved February 3, 2021, from https://www.franchisehelp.com/industry-reports/chocolate-industry-analysis-2020-cost-trends/

Glossary of Terms and Definitions. (n.d.). Thermtest Inc. Retrieved December 21, 2020, from https://thermtest.com/thermal-resources/glossary

Sun, D.-W. (2012). Thermal Food Processing: New Technologies and Quality Issues, Second Edition. CRC Press.

Unsplash. (n.d.). Beautiful Free Images & Pictures | Unsplash. Retrieved February 5, 2021, from https://unsplash.com/

What’s the Difference Between Conduction, Convection, and Radiation? (2015, October 30). Machine Design. https://www.machinedesign.com/learning-resources/whats-the-difference-between/document/21834474/whats-the-difference-between-conduction-convection-and-radiation