July 26, 2023

Silver, the lustrous metal known for its beauty and value, plays a crucial role beyond its ornamental and monetary significance. In modern technology, silver has established itself as a preferred conductor in electronic components, powering the devices that have become an integral part of our daily lives. In this blog, we will delve into the world of silver in electronics, exploring its benefits, comparing it to other conductive materials, and peering into the future to see how this trend will likely evolve.

Imagine a world without electronic devices—no smartphones, computers, or modern communication systems. The role of silver in these devices is indispensable. Its exceptional electrical conductivity makes it an ideal choice for transmitting and regulating electrical signals, powering our gadgets, and enabling seamless communication. Silver’s ability to efficiently carry electrical current is far superior to most other metals, making it an ideal choice for high-performance electronic applications.

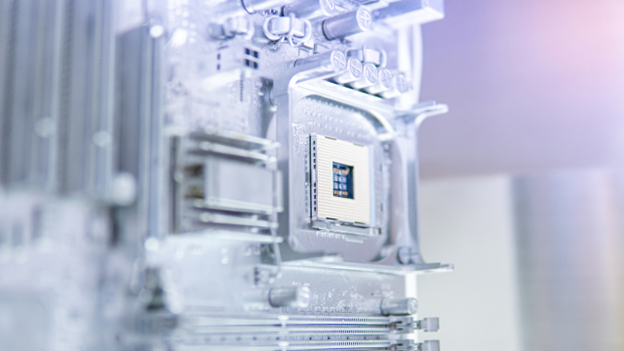

Silver is essential in a wide range of electronic devices, from small-scale applications like microchips and sensors, to larger components in power electronics and communication systems. In microelectronics, silver is used as interconnects on integrated circuits, connecting various components on a chip to facilitate data flow. Silver’s low electrical resistance and minimal losses during signal transmission contribute to the electronic devices’ overall efficiency and performance.

Furthermore, the thermal conductivity of silver signifies its suitability for applications where heat dissipation is critical, such as in power electronics. It helps in efficiently dissipating heat generated during the operation of power devices, preventing overheating, and ensuring the devices’ longevity and reliability.

Figure 1. Silver in Electronics – Microchip

Regarding conductivity, copper is silver’s primary competitor. Both metals exhibit impressive conductivity properties, but each has strengths and weaknesses. While silver boasts superior conductivity, copper holds the advantage of being more cost-effective. Engineers and manufacturers base decisions on whether to use silver or copper on the specific requirements of the electronic components they are designing.

In high-end electronic applications where performance is paramount, and cost is of less concern, the exceptional conductivity of silver often justifies its use. In contrast, copper is more commonly used in mass-produced consumer electronics due to its lower cost. This cost-performance trade-off has led to various applications that utilize either silver or copper (or even combinations of both) to optimize performance while managing production costs.

Despite the cost difference, silver and copper have found their respective niches in the electronics industry, contributing to the seamless functioning of the electronic devices we rely on daily.

The versatility of silver extends beyond its use as a pure conductor. In recent years, silver nanoparticles have gained traction for their unique properties. These tiny silver particles, typically less than 100 nanometers in size, have intriguing attributes. Silver nanoparticles have a significantly higher surface-area-to-volume ratio than bulk silver, providing enhanced reactivity, making them suitable for various specialized applications in electronics.

One of the notable applications of silver nanoparticles is in conductive inks used for printing electronic circuits. Unlike traditional methods of circuit fabrication, which involve photolithography or etching processes, printed electronics offer a cost-effective and versatile alternative. Silver nanoparticle inks can be applied on flexible substrates through various printing techniques, allowing the production of flexible and lightweight electronic devices, including wearable technology and flexible displays.

Figure 2. Silver in Electronics – Wearable Technology, Smartwatch

Another area where silver nanoparticles shine is in enhancing the performance of electronic displays. Silver nanowires manufacture transparent conductive films, which act as electrodes in touchscreens and displays. These nanowire-based films offer superior transparency, flexibility, and conductivity compared to conventional indium tin oxide (ITO) films, making them well-suited for next-generation electronic displays.

In addition to silver nanoparticles, silver coatings have become increasingly popular due to their ability to protect electronic devices from corrosion and other forms of degradation. These coatings serve as a protective barrier, safeguarding sensitive electronic components from environmental factors like moisture, dust, and pollutants. Furthermore, silver’s antimicrobial properties have been harnessed in developing electronic devices used in medical settings, reducing the risk of bacterial growth on surfaces, and contributing to maintaining a sterile environment.

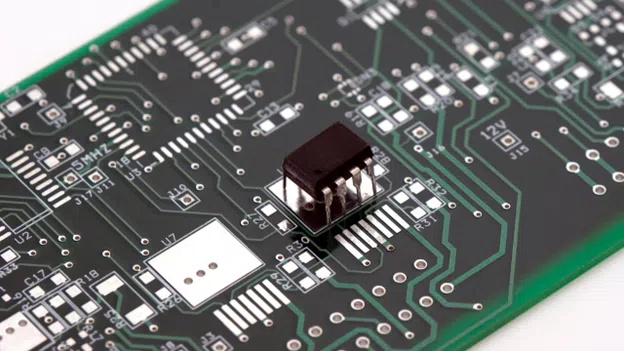

Circuit boards are the backbone of electronic devices, and silver plays a significant role in their construction. Silver plating, a process where a thin layer of silver is deposited onto the circuit board’s surface, enhances the board’s conductivity and protects against corrosion. Silver plating ensures that the electrical connections on the circuit board remain stable and free from oxidization, ensuring the long-term reliability of the device.

Silver plating is crucial for high-frequency and high-speed circuit boards, as it minimizes signal losses and reduces electromagnetic interference. These benefits make silver-plated circuit boards the preferred choice in applications like telecommunication networks, satellite systems, and advanced data centers.

Figure 3. Silver in Electronics, Circuit Board

While silver plating offers various advantages, it has challenges. The environmental impact of silver mining and plating processes has raised concerns, prompting the industry to explore more sustainable alternatives. Researchers are investigating environmentally friendly plating methods and searching for ways to minimize silver usage without compromising the performance and reliability of electronic devices.

As technology advances, so will the role of silver in electronics. Researchers and innovators continuously explore new applications and push the boundaries of what is possible with silver. The future holds exciting possibilities for silver in the electronic realm, from nanotechnology to flexible electronics.

Silver will continue to play a vital role in Nanotechnology. Silver nanoparticles are being researched for their potential application in enhancing energy storage devices like batteries and supercapacitors. The increased surface area of nanoparticles could improve electrode performance and contribute to developing more efficient and longer-lasting energy storage solutions.

Another promising area is the integration of silver into flexible and wearable electronics. Silver’s high conductivity and mechanical flexibility make it an ideal candidate for use in bendable electronic components. Flexible electronics hold immense potential for various applications, including wearable health monitors, rollable displays, and even electronic textiles.

Furthermore, with the rise of the Internet of Things (IoT) and the increasing interconnectedness of devices, the demand for smaller and more efficient electronic components will continue to grow. Silver’s conductivity and thermal properties position it well for fulfilling these demands in the design of compact and powerful electronic systems.

In conclusion, silver’s significance in the world of electronics cannot be overstated. Its exceptional conductivity, versatility in nanoparticle form, and protective coatings make it an invaluable component in electronic devices. Silver’s role will only grow as we look to the future, driving innovation and pushing the boundaries of what technology can achieve. Whether it’s in our handheld devices or powering complex communication networks, silver remains at the forefront of technological progress. So, next time you use your smartphone or send an email, take a moment to appreciate the unassuming but mighty presence of silver in enabling these modern marvels.

Lee, C., et al. “Comparison of Silver and Copper Conductors for High-Speed Digital Applications.” IEEE Transactions on Advanced Packaging, vol. 39, no. 3, 2016, pp. 620-626.

Patel, R., and Johnson, A. “Antimicrobial Properties of Silver and Its Potential Applications in Electronic Devices.” Materials Science and Engineering: B, vol.