November 27, 2015

Nuclear fusion power has been widely researched as a future sustainable energy source. Fusion reactors mimic stars in that they use the thermal energy produced through the fusion of deuterium and tritium (the two heavy isotopes of hydrogen) nuclei in the form of plasma to give helium. Thermal conductivity testing is one area of research that is being used to help develop these reactors. The thermal energy produced by this reaction can be used to generate electricity without releasing harmful carbon dioxide to the atmosphere.

The largest hurdle that must be overcome prior to the practical application of this concept is to find the most durable and cost-effective material for the construction of reactors that are capable of containing these high energy particles. One commonly used method is magnetic confinement in which a magnetic field is generated in a torus (donut-shaped figure, Figure 1). The magnetic field causes the plasma to circulate around the torus without losing energy through contact with the walls; however, even with these magnetic fields, the walls of the reactor are still subjected to neutron radiation and extreme temperatures which can cause cracking and eventually catastrophic thermal failure of the reactor. For this reason, these reactors must be made of a material with a high thermal conductivity. The material being most commonly researched for this purpose is tungsten.

A recent news release from phys.org describes work being done by researchers at Oxford University in collaboration with MIT and the Culham Centre for Fusion Energy to determine the effect that the intense neutron radiation produced by nuclear fusion has by testing thermal conductivity in a simulated model of the walls in a nuclear fusion reactor.

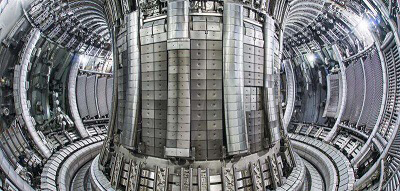

Figure 1. The Joint European Torus (JET) nuclear fusion reactor located at the Culham Centre for Fusion Energy.

Helium ion bombardment has been used to simulate the extreme conditions that the reactor walls are subjected to on a laboratory scale. This process involves the bombardment of tungsten metal with high-energy helium ions, creating a very thin layer of irradiated material. Rather than using more traditional thermal conductivity equipment, the researchers have adopted a method known as laser-induced transient grating spectroscopy for the testing of thermal conductivity of this simulated model. This method, which had previously been used for thermal conductivity measurements in silicon semiconductors, involves the subjection of a sample to short overlapping laser pulses which causes a change in the refractive index of a given sample. The relaxation of this change is monitored by a third laser beam, known as a probe beam, which is used to determine information regarding heat diffusion in the sample. This method was chosen because it is an accurate method of testing thermal conductivity near the surface of a sample.

The results of the laser-induced transient grating spectroscopy showed that the damage caused by the radiation decreased the measured thermal conductivity by up to fifty percent, thus decreasing the reactor’s ability to respond to a temperature increase and significantly decreasing its lifetime; therefore, further work must be done to determine a more suitable construction material for these reactors.

The full news release from phys.org can be found here:

http://phys.org/news/2015-11-thermal-tolerance-fusion-reactors-future.html

A copy of the research paper on this subject published in Scientific Reports can be found at:

Sources

http://www.world-nuclear.org/info/current-and-future-generation/nuclear-fusion-power/

Käding, O. W., Skurk, H., Maznev, A. A. & Matthias, E. Transient thermal gratings at surfaces for thermal characterization of bulk materials and thin films. Appl. Phys. A 61, 253–261, doi: 10.1007/BF01538190 (1995).