December 13, 2021

The construction sector is a massive industry in Canada that is currently providing jobs for approximately 1.2 million Canadians. This equates to an impressive 7% of the entire country’s workforce. As Canada’s population and economy continue to grow, so will the need for high quality infrastructure and housing. Contractors and builders are starting to place a stronger emphasis on using high performance building materials, especially ones with desirable thermal properties, for meeting this steadily increasing demand.

The desire for more thermally significant building materials is fueled by the need for more energy conservation, which is gaining importance in almost every country across the globe. In the majority of developed nations, building practices and construction account for almost half of the total energy consumption as well as being the source of environmentally harmful CO2 emissions.

A considerable amount of research has been underway in an attempt to discover and implement more environmentally friendly and sustainable building practices and methods to replace the outdated and hazardous ones currently being employed. One area in this field of research is centered around using more renewable resources (such as clay) for the development and fine tuning of popular and widely used building materials.

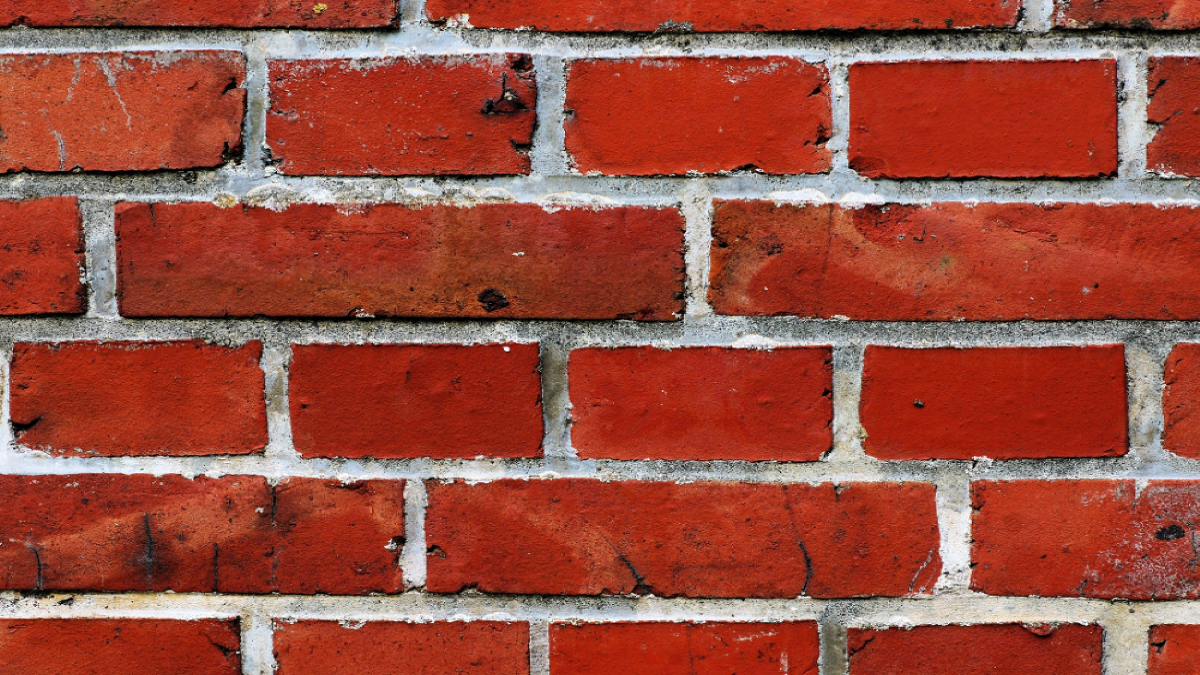

Clay is simplistic earth derived material that has been used for building homes and other types of infrastructure since 7000BC making it one of the oldest construction materials in this history of civilization. The popularity of clay bricks has not wavered since its first use thousands of years ago as it is still the most sought-after building material across the entire planet. Recent surveys have estimated that at least one third of the global population resides in some type of earth derived dwelling made of clay or a structurally similar material.

The high use of this resource across the entire planet represents just how important it is to consider all of the properties of natural clay materials in order to fully harness all of the beneficial physical and thermal aspects to construct the most efficient brick for building purposes.

A growing area of interest among professionals in this sector involves looking into the use and applications of brick as a sustainable material. The basic composition of bricks consists of two different materials bonded together in a specific way so that one serves as the matrix surrounding the reinforcing material.

The two most common materials used are low moisture clay and shale which are forced into molds and then allowed to set before being cut into smaller, uniform pieces to form individual bricks. Clay bricks are a combination of purely natural elements including clay, sand, water, and air. No toxic substances are added to bricks during their formation as they are made entirely from inert materials that pose no risk to humans.

It is important for contractors to consider the toxicity of building materials before using them, especially one that is exposed to the surrounding environment as these can potentially erode and contaminate the surrounding soil or nearby waterways. Luckily this is not a concern when building with brick as it is made entirely of earth derived materials and normally without the addition of any man-made substances. Clay and loam, two common materials present in bricks, are seemingly inexhaustible resources.

The excavation processes used to remove clay from its natural location are only temporary and cover a limited surface area so it is relatively noninvasive to surrounding natural habitats. After excavation, the site is reconstructed, and most areas experience a relatively rapid recovery to their original unaltered state.

Figure 1: Excavators extracting clay from an open industrial quarry.

Clay bricks offer a unique economical advantage to a homeowner in terms of saving them money on their heat and power bill. Building a house made of brick may seem like a steep investment initially but it is undoubtedly one that will pay off in the long run. Bricks possess a low thermal conductivity which averages between 0.5 – 1.0 W/(m/K). The thermal conductivity of a material directly relates to its ability to effectively transfer heat through it.

Materials with a low thermal conductivity, like a clay brick, are said to be thermal insulators as they restrict the movement of heat passing through them. This thermal property is extremely desirable in terms of building a house as it provides indoor temperature regulation by restricting cold air from entering the home and blocking warmer indoor air from escaping into the surrounding environment.

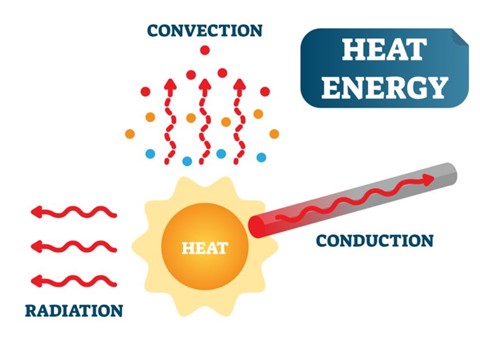

The ambient temperature of a house is impacted via three main modes of heat transfer which include conduction, convection, and radiation. The majority of heat movement through a building can be attributed to conduction as heat moves differently through materials with varying thermal conductivity values. Clay bricks have a low thermal conductivity, most of which can be attributed to the presence of cavities that contain air bubbles and spaces between them.

Air has an extremely high thermal resistance and low thermal conductivity giving bricks an even greater insulating ability. A material with a high thermal resistance restricts heat transfers and is the property that enables bricks to act as a natural air conditioner in the hot summer months or a powerful heater in the winter.

Figure 2: Mechanism of heat transfer.

Unfortunately, the insulating power of bricks is not uniform throughout all areas and climates in the world. In tropical regions that experience an average annual temperature between 22-35 ºC, bricks act as an excellent insulating material and can maintain a cooler indoor temperature despite the hot surrounding environment.

In areas where temperatures will frequently drop below 10ºC, the insulative strength of brick can be compromised due to a change in the moisture thermal balance and in some cases can initiate moisture problems such as freeze-thaw damage to a structure or wall. This risk has many interior designers searching for ways to avoid this problem which is one that can result in major energy losses, in turn making a building less comfortable and usable than if it were properly insulated.

One emerging solution to this problem is incorporating other materials with similar thermal properties into the construction of bricks to enhance their insulative ability and protect them from water damage. The most effective additions to bricks are currently glass wool or natural cork as well as polyethylene plastic.

Figure 3: Glass wool insulation – used as a common additive during the formation of clay bricks.

Figure 4: Natural cork – used as a common additive during the formation of clay bricks.

A number of manufacturers are also incorporating waste materials into the construction and formation of their clay bricks. This growing trend among production companies can likely be attributed to the push from consumers and local governments for more sustainable building practices and resource extraction.

Organic waste has occasionally been incorporated into bricks and was found to have excellent energy saving capabilities and outstanding thermal insulation properties. Another avenue some companies are taking involves the inclusion of recycled paper to improve a brick’s thermal resistance.

The list of materials that could be included in the formation of clay bricks is constantly growing, however, this high demand for bricks is placing increased pressure on alluvial soil reserves which are at risk of being depleted. As the demand for sustainable building materials continues to soar, avoiding overexploitation will become even more important for companies in this sector to consider especially if consumers continue to replace materials like steel and concrete with clay bricks. Research in this area is ongoing as new mixtures are continuously being tested for thermal and energy related benefits.

Figure 5: Construction worker laying and setting clay bricks.

Clay Bricks are among the oldest building materials on earth having been a key part of the construction and development of ancient architecture. Fast forward to the 21st century and they are still the most popular building material across the entire planet. Most of their popularity can be linked to their low thermal conductivity, high thermal resistance, and ability to be sustainably extracted and processed.

As the global focus continues to shift towards creating a greener planet, the evolution and refinement of the materials bricks are composed of will continue to center around increased thermal resistance to promote a more energy efficient building by limiting unnecessary heat flow.

In climates similar to Canada that are all but too familiar with harsh and cold winters, being able to conserve heat and save money by lowering energy use is extremely beneficial for both the homeowner and the environment. Building houses and infrastructure with clay bricks can provide all of these energy and resource saving benefits simply by properly utilizing the naturally occurring characteristics of this sustainable resource.

Author: Kallista Wilson | Junior Technical Writer | Thermtest

Deboucha, S., & Hashim, R. (n.d.). A review on bricks and stabilized compressed earth blocks. Sci. Res. Essays, 8.

Does A Brick Home Need Insulation? | Brick Siding. (2020, March 20). Modern Design. https://gambrick.com/does-a-brick-home-need-insulation/

Dondi, M., Mazzanti, F., Principi, P., Raimondo, M., & Zanarini, G. (2004). Thermal Conductivity of Clay Bricks. Journal of Materials in Civil Engineering, 16(1), 8–14. https://doi.org/10.1061/(ASCE)0899-1561(2004)16:1(8)

Manufacture of lightweight clay bricks with improved thermal insulation properties via the incorporation of spent shea waste. (n.d.). Retrieved December 4, 2020, from http://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S1665-64232018000300186

Points to Consider When Purchasing Ultra-Low Temperature Freezers. (2017, August 2). News-Medical.Net. https://www.news-medical.net/whitepaper/20170802/Points-to-Consider-When-Purchasing-Ultra-Low-Temperature-Freezers.aspx

Vasić, M., Lalić, Ž., & Radojević, Z. (2010). CLAY BRICK WALLS THERMAL PROPERTIES. International Journal of Modern Manufacturing Technologies, 2.