November 21, 2019

The benefits of using extremely thermal resistive batt insulation to reduce energy consumption and lower power bills.

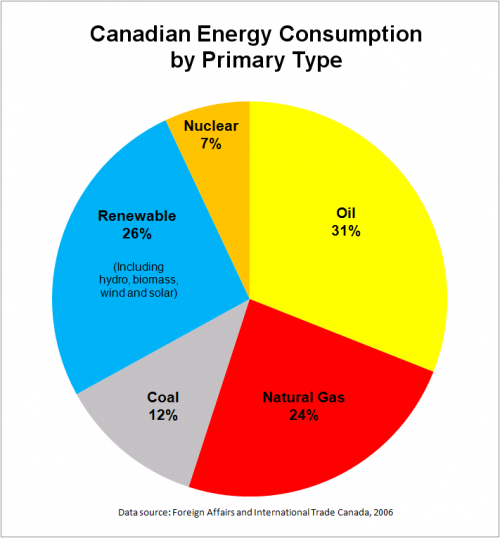

Energy is the groundwork for modern living. Millions of tools and technologies harness the power energy provides to allow a comfortable living environment for most of the people. As these technologies continue to develop and become more efficient, the demand for energy continues to grow. The average household spends an estimated 7.9% of its income on energy costs. This percent will grow as carbon taxes and strict regulations are placed around the extraction and use of fossil fuels and non-renewable resources. As these costs increase, Canadian families are finding it more difficult to obtain the amount of energy needed for daily living. In order to combat growing energy demands, current technologies and appliances need to adapt to become more energy efficient. Increasing the quality of insulation in homes and buildings across the country is an energy saving alternative that has the potential to substantially lower a households’ expenses. This change can be applied by using insulation materials with a higher thermal resistance to create a stronger barrier that resists heat flow.

Figure 1: Canadian energy consumption by primary type of resource/fuel

Figure 2: Canadian energy consumption (TWh/y) measured by different types of energy sources

Thermal resistance is considered the inverse of thermal conductivity. It can be measured by observing a material’s ability to resist the flow of heat through it. A material with a high thermal resistance is slow to transfer heat and therefore will lose less heat to its environment. Thermal resistance is expressed as an R-value which is a function of the thickness and conductivity of a material. A material with a high R-value has good insulation properties and a high thermal resistance. Many production companies rely on the thermal properties of materials when designing numerous tools and technologies. Construction is an industry that places a heavy reliance on materials with good thermal resistance properties. Construction companies frequently utilize these thermal materials when fabricating the insulation in houses and buildings. Insulating houses requires materials with a large R-value (high thermal resistance) to ensure minimal heat transfer and energy loss.

Selecting an insulation is largely dependent on where it is being installed (ex. attic, basement) and the climate that the building or house is located in. Colder climates generally require insulation with an R-value ranging from 49-60 per inch. To achieve R-values large enough to combat cold climates, generally multiple layers of isolation are needed. These factors are important to consider when selecting a material to use as an insulator in a building or home. Table 1 outlines some common materials that are used as insulators and their primary properties.

| Type | Material | Where to use it | Advantages |

|---|---|---|---|

| Blanket: batts and rolls |

|

Tight areas, between studs, pipes and beams |

|

| Concrete block insulation |

|

Unfinished walls Foundations(new construction projects) |

|

| Foam board or rigid foam |

|

|

High insulation value for low thickness |

| Insulating concrete forms (ICFs) | Foam boards or foam blocks | Unfinished walls (including walls for new construction) | Insulation built right into homes walls creating high thermal resistance |

| Loose-fill and blown-in |

|

|

|

| Reflective system |

|

|

|

| Sprayed foam and foam-in-place |

|

|

|

| Structural insulated panels (SIPs) |

|

Unfinished walls, ceilings, floors and roofs for new construction |

|

Batt insulation has been the most popular and frequently used form of insulation since the accidental discovery of fiberglass in 1930. It can be composed of a variety of materials including; fiberglass, rock (mineral) wool, plastic or natural fibers. Batt insulation is normally manufactured in precut blocks or blankets of multiple shapes and sizes that can be hand cut and sized to fit specific areas. This type of insulation can also include facings built of Kraft paper, foil Kraft paper or vinyl that act as a vapor or air barrier. These facings help protect the insulation material from moisture exposer or rotting. The two most prominent types of batt insulation are made of fiberglass or rock wool.

Materials with a higher thermal resistance often have a very low density. The resistance is higher because heat and energy take additional time to travel through a low-density material due to the extra space between atoms. A Cottonball is a great example of a low-density object with a high thermal resistance. Cottonballs are composed of widely spaced fibers surrounded by large air pockets. Cotton has an extremely similar molecular and physical structure to fiberglass, one of the leading insulators in the construction industry.

Figure 3: Pink fiberglass batts insulation

Fiberglass has been the most popular insulation for over 80 years. It is a convenient, easy to install, affordable option for “do it yourself” home owners. Fiberglass is formed when extremely fine glass particles adhere together after being treated with a chemical bonding spray. It can be installed in the form of blankets and batts or loose filled and blown in to the area requiring insulation. Fiberglass is manufactured to be low or high density with low-density R-values of 11 and high-density values of 15. The lower density option is convenient for homes that require layered insulation so a more accurate R-value can be achieved. Fiberglass is a flexible material that can be easily molded around pipes and floor boards to achieve maximum insulation coverage. It is also crucial when installing fiberglass to not compressed the material. The additional air pockets in the material help increase the thermal resistance and make it more difficult for heat to pass through.

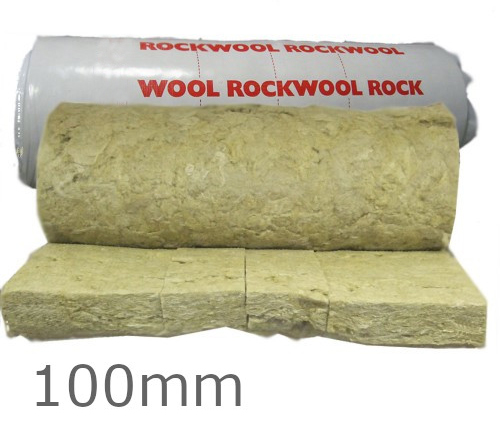

The new competitor threatening the popularity of fiberglass is rock wool insulation. Rock wool (also known as mineral wool) is formed by melting basalt and slag at 3000°F (slag is a waste produced during the production of steel). The heated substance is then strung into long strands using steam pressure and compressed into dense mats. Rock wool is a naturally fire-resistant substance without any chemical treatments, so it is frequently used as a blockade. It is manufactured into extremely thick mats that can be easily installed without the use of staples or additional tools. As a naturally water-resistant material, rock wool can resist moisture build up, mold and rot. Table 2 below compares the two varieties of insulation.

Figure 4: Standard rock wool (mineral wool) batts insulation

| Factor | Fiberglass | Rock Wool |

|---|---|---|

| R-Value | 2.2 – 2.7 per inch | 3.0 – 3.3 per inch |

| Size | Wide range of sizes | Only available in unfaced batts |

| Sustainability | 20 – 30% recycled material | 70% < recycled materials |

| Cost | 2×6 wall costs $0.57 – $0.72 per Sq. Ft | 2×6 wall costs $1.00 – $1.10 per Sq. Ft |

| Density | 0.5 – 1 Lbs. per cubic ft | 1.7 Lbs. Per cubic ft |

| Water resistance | Not resistance to moisture | Hydrophobic – fully water resistant |

| Loose-fill | Quick, easy, economical | Does exist but difficult and expensive to find |

| Installation | Come in multiple sizes and can be shaped/cut with a serrated blade – requires staples | Dense, firm batts friction fit into place – no staples required |

| Fire resistance | Noncombustible | Extremely fire resistant |

Fiberglass and rock wool are both effective insulations that increase energy saving and lower the amount of power consumed by a household. Many buildings and homes are insulated using both rock wool and fiberglass. This is a more cost effective alternative and proper installation can harness the benefits of both fiberglass and rock wool. When industries and construction companies take into consideration the thermal properties of material, extra opportunities arise to engineer the most heat efficient product. Energy is becoming a more valuable resource so every opportunity to conserve and harness the most power from energy should be taken advantage of. Installing effective insulation into a home is just a small example of how Canadians can start acting towards reducing consumption and protecting future resources for generations to come.

Green, K. Jackson, T. Herzog, J. Palacois, M. (2016, March). Energy Costs and Canadian Households. Fraser Institute. Retrieved from: https://www.fraserinstitute.org/sites/default/files/energy-costs-and-canadian-households.pdf

Contributor. (2017, March 24). What’s the Difference: Fiberglass vs. Mineral Wool Insulation. Retrieved from https://www.thehousedesigners.com/blog/whats-difference-fiberglass-vs-mineral-wool-insulation/

Thermal Conductivity, Thermal Resistance, R & U-Values. (2018, February 20). Retrieved from https://www.insulationexpress.co.uk/guides/insulation/thermal-conductivity-thermal-resistance-r-u-values/

Types of Insulation. (n.d.). Retrieved from https://www.energy.gov/energysaver/weatherize/insulation/types-insulation

Images:

https://upload.wikimedia.org/wikipedia/commons/9/9e/Canadian_Energy_Consumption_by_Type.PNG

https://upload.wikimedia.org/wikipedia/commons/9/9d/Bp_world_energy_consumption_2016.gif

https://www.curezone.org/upload/Art/fiberglass_insulation.jpg

https://www.insulationshop.co/image/catalog/product/Rockwool/rockwool_rollbatt_loft_insulation_100mm.jpg

https://www.e-education.psu.edu/egee102/sites/www.e-education.psu.edu.egee102/files/images/Lesson_07/L7_HeatLoss2.gif

Author: Kallista Wilson, Junior Technical Writer at Thermtest