February 28, 2023

Although often overlooked, the secret to drastically lowering home energy usage and heating bills is contained directly within the walls that surround us. High-quality insulation is a crucial component of any energy-efficient home or building as it serves as a tight barrier separating the temperature-regulated indoor environment and the harsh exterior by directly blocking air and heat exchange. Homeowners dedicate a significant amount of money to maintaining a comfortable interior temperature, especially in climates prone to severe weather and cold temperatures. This task becomes significantly easier if the building is equipped with high-quality insulation as it reduces the demand placed on a heating or cooling system. Not only does insulation lower energy bills, but it also directly correlates to a reduction in the amount of greenhouse gas emissions released by a home or building. As climate change continues to become a greater concern in the eyes of the average consumer, many are looking for ways to reduce their carbon footprints as much as possible. Lowering home energy use is an excellent step towards achieving a net zero-carbon home as the US residential sector consumed 96% of all nationally produced energy in 2021, an all-time high throughout history. Of this residentially consumed energy, over 41% was strictly a result of space heating and cooling with this sector also accounting for the biggest energy losses and wastage. While these numbers may be haunting during a time of widespread economic and environmental concern, thankfully there are several different climate-friendly replacements available for conventional and outdated insulation materials that offer excellent thermal protection and limit the carbon footprint of a consumer.

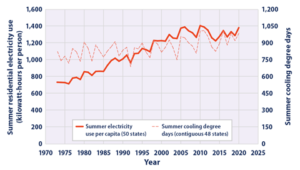

Figure 1: Electricity use in the summer months in the US compared to cooling degree days

A carbon footprint is calculated as an estimate of the amount of carbon dioxide (or other carbon compounds) emitted by an individual due to their consumption of fossil fuels. This same idea can also apply to an activity or a physical object such as a home or building. A home that is power hungry and demands a significant amount of energy to fuel it, whether that fuel is used for heating or electricity, can inflict more harmful effects on the environment than one that is conservative in its energy usage. As the harmful impacts of climate change continue to escalate and become more known to society, many individuals are searching for ways to lower their carbon footprint and therefore, their impact on the environment. This eco-conscious mentality has spiked interest in the use of bio-based construction materials for homes and large commercial buildings with the goal of transforming these emitting structures into carbon sinks.

Engineering and designing a home to be a carbon sink or a zero-carbon dwelling involves comparing the effects of carbon sequestration and storage from a life cycle perspective. This entails a rough analysis of all the various processes taking place throughout different periods of home construction and operations across ecological, technical, and economic domains. Some buildings have even been designed with the intended purpose of sequestering carbon. These unique structures remove carbon dioxide from the atmosphere by containing various amounts of plant matter such as wood, cork, hemp, and algae. Plants naturally capture carbon when they undergo photosynthesis as it is a key ingredient for fueling their growth. Aside from directly using the captured carbon, many plants will turn it into a bi-product or other materials that are later stored in the surrounding soil.

Figure 2: Simplistic depiction of photosynthesis

In the construction industry, a material is classified as carbon negative when it contains more carbon than what was emitted during its creation. This also takes into consideration the materials and energy used to manufacture the product. Mycelium insulation is an excellent example of an up-and-coming insulation material that is natural fire retardant and can remove upwards of 16 tonnes of carbon from the atmosphere in a single month. Mycelium is a weblike biological material that grows on the root system of fungi. It generates its energy by feeding on agricultural waste and while doing so, sequesters the carbon that is stored in its biomass. Shockingly, this bio-based material processes better insulation abilities than several other popular synthetic materials currently on the market. Mycelium is a relatively inexpensive material to manufacture artificially, a process that involves creating the substance in bioreactors. This unique method of making a natural material inflicts minimal damage to the environment and helps limit the amount of mycelium excavation from natural ecosystems.

Figure 3: Mycelium root network of a fungi plant

Wood is another excellent and simplistic example of a material with carbon-capturing capabilities. A full-grown tree has the potential to remove upwards of 22kg of CO2 from the atmosphere over the course of a year, which classified it as being carbon negative. The extent of this atmospheric carbon-reducing ability is unfortunately very reliant on the harvesting method. For harvested wood to be deemed an environmentally friendly material, it must be sustainably harvested with new trees being planted to compensate for those that were felled. The wood treatment and manufacturing processes also need to be accounted for when calculating the carbon emissions associated with wood insulation. This would include transportation, processing, planting replacements and ensuring that trees are left growing for a long enough period prior to their harvest that they can effectively transform atmospheric pollution into a carbon-storing material. Wood or wood chips can be incorporated into several different areas of a home whether it be within the insulation or as a part of the solid structure. For example, a recent study showed that replacing asphalt shingles with plastic/wood fibre shingles reduced embodied energy by 98% over 50 years.

Cellulose insulation has been crowned the king of eco-friendly materials in the insulation world as it contains anywhere from 75% to 85% recycled material. This innovative material is primarily made of recycled newspapers, cardboard, or denim that has been finely shredded and treated with several different chemicals. These chemicals keep this paper-based insulation fire-resistant and are primarily boric acid, borax, or ammonium sulphate all of which are known to be non-hazardous to humans and animals. Cellulose insulation can be installed as loose-fill blown-in insulation, densely packed into floors and walls or wet sprayed into new constructions. Densely packed cellulose is the most common form used today and is an excellent inclusion into pre-existing structures for retrofitting purposes. Cellulose insulation has an R-value between 3.1-3.8 per inch of material which is in the mid-range of most modern insulation materials.

Figure 4: Cellulose Insulation

In January 2021, Environment and Climate Change Canada placed a ban on the use of HFC-blowing agents in insulation, a popular medium for use in foam and rigid board insulation products such as expanded polystyrene (XPS). This new legislation prompted many manufacturers and insulation installers to reconsider the amount of embodied carbon their products contained. Despite numerous insulation materials proving to be extremely effective throughout their operational lifetime at reducing atmospheric carbon emissions by lowering building energy use, there is still a significant trade-off between this operational excellence and the embodied carbon the material contains. In order to assist the insulation industry with this rapid adjustment to the new nationwide protocol, KPMB Labs conducted a study analyzing the embodied carbon of a number of popular insulation materials including extruded polystyrene (EPS), stone wool, extruded polystyrene (XPS), polyISO, spray foam, fibreglass batt, and more. This study proved to be an excellent tool to calculate the number of years it would take for the operational carbon savings to exceed the insulation’s embodied carbon, much of which pertains to the material’s global warming potential (GWP).

In the KPMB study, the GWP of 11 insulation materials was calculated at a thermal resistance of 1 per square meter of material. These measurements were adjusted to reflect the material’s behaviour over a 30-year service life. The embodied carbon was then calculated at varying insulation thickness levels to achieve R1 to R40. The thermal resistance of a material reflects its ability to prevent the flow of heat through it with higher R-values indicating a superior insulation material. This study revealed that XPS insulation was the highest emitting and had the longest pay-back period even after the new 2021 regulations were implemented. The magnitude of emissions associated with XPS where 15-20x’s greater than other insulation materials with even recently manufactured materials inflicting more environmental impacts than other competitors. Blown-in cellulose had the lowest embodied carbon due to the minimal amount of processing required to make it. Polyiso, EPS, stone wool, and GPS also all have lower embodied carbon than XPS.

This study also further confirmed that the payback time for most insulation materials decreases from 30 years to 16 years when insulation thickness is increased from an R4 to an R24. A further increase in thermal resistance would therefore lead to fewer carbon emissions due to the ability of the structure to better minimize the amount of heat loss occurring. A greater R-value can be achieved in several ways with the most common being increasing insulation thickness in the walls or roof.

The environmental benefits of certain biobased insulation materials were further highlighted by the KPMG study as it showed a significant decrease in the amount of embodied carbon contained within cellulose, hemp, wood, and straw insulation materials. The biogenic materials these insulations are made of regularly undergo photosynthesis in which they sequester atmospheric carbon dioxide by transforming it into biomass or placing large quantities into the surrounding soil. If the carbon sequestered out of the atmosphere is greater than the carbon emitted during the extraction, manufacturing, and installation of these insulation materials, they can be classified as carbon sinks. Although this practice has yet to become mainstream in North America, numerous studies have shown the use of these eco-friendly insulation materials is highly beneficial and feasible for a range of applications. Protecting a home from heat loss by means of installing secure and thermally resistant insulation is just one step towards creating a more energy-efficient society. Selecting an insulation material will low GWP and high embodied carbon are just the cherry on the cake in the process of becoming a net-zero home or building. Home and building owners that take action towards transforming their home energy usage will inevitably play a massive role in combatting climate change by limiting our reliance as a society on excess energy usage and waste.

Crail, C. (2022, September 26). Your Guide To Understanding Blow-In Cellulose Insulation. Forbes Home. https://www.forbes.com/home-improvement/home/blow-in-cellulose-insulation/

Does Your Insulation Have Low Embodied Carbon? (2020, July 21). GreenBuildingAdvisor. https://www.greenbuildingadvisor.com/article/does-your-insulation-have-low-embodied-carbon

Residential Buildings Factsheet. (n.d.). Center for Sustainable Systems. Retrieved November 28, 2022, from https://css.umich.edu/publications/factsheets/built-environment/residential-buildings-factsheet

Ringler, A. (n.d.). What is Cellulose Insulation? What’s it Made of and How Does it Work? Retrieved November 9, 2022, from https://www.retrofoamofmichigan.com/blog/what-is-cellulose-insulation-material

says, H. P. T. B. gets new life as a net zero hotel-G. to Z. F. (2020, January 23). Choosing Insulation for Carbon Value – Why More is Not Always Better Part 2. Steven Winter Associates, Inc. http://www.swinter.com/party-walls/choosing-insulation-for-carbon-value-why-more-is-not-always-better-part-2/

Secretary Granholm Announces New Building Energy Codes To Save Consumers Money, Reduce Impacts Of Climate Change. (n.d.). Energy.Gov. Retrieved November 7, 2022, from https://www.energy.gov/articles/secretary-granholm-announces-new-building-energy-codes-save-consumers-money-reduce-impacts

Ten materials that store carbon and help reduce greenhouse gas emissions. (2021, June 27). Dezeen. https://www.dezeen.com/2021/06/27/carbon-negative-carbon-neutral-materials-roundup/