March 30, 2021

The uses and importance of heat exchangers for common dairy processing procedures

Heat exchangers are a fundamental aspect of dairy processing and are heavily relied on by producers to ensure that their milk products satisfy industry standards and are safe for consumption. Liquid milk is a relatively stable fluid that presents few challenges in terms of handling and processing. Due to milk’s ability to be easily temperature regulated, most dairy companies use simple plate-type heat exchangers to perform tasks such as pasteurization, sterilization, and other food processing operations. Despite the simplicity of handling liquid milk, other dairy products, such as yogurt, butter, curds, and cheese, all require different processing and storing temperatures. If handled incorrectly, they may have their key parameters damaged by routine procedures. Therefore, it is important for companies processing dairy products to select a heat exchanger that is best suited to the type of product they are producing. Some important parameters that need to be considered when selecting a heat exchanger are product texture, viscosity, particle size, and how it behaves during routine production and processing.

Figure 1: Standard bottling procedure at a dairy processing plant.

Before heat treatment was introduced as common practice for processing dairy products, most milk products were considered a potential source of infection because they are an ideal growth medium for many microorganisms that can cause harmful diseases such as tuberculosis and typus. A substantial amount of research went underway to determine a treatment that could be used to make milk safer for consumption. It was not until the mid-19th century that a solution to this problem was finally discovered. Pasteurization is a term coined by Louis Pasteur, who studied the effects of heat on microorganisms found in dairy products. His findings led him to propose the use of heat as a preservative and treatment technique. All common pathogenic organisms that likely occur in milk are killed by relatively minor heat treatment, making the product aseptic, which will only slightly affect the milk’s physical and chemical properties.

Figure 2: Microorganism that causes the extremely harmful disease known as tuberculosis.

The most resistant organism that can be found in dairy products is the Tubercule bacillus (T.B.), which is killed when milk is heated to 63°C for a duration of 10 minutes. Complete safety can be assumed when milk is heated to at least this temperature but for a duration of 30 minutes instead of 10. Due to its persistence, T.B. is considered the index organism for pasteurization, meaning any treatment that destroys T.B. can be relied on to destroy other pathogens present in milk.

Ultra-high temperature (UHT) processing is desirable from a microbiological point of view; however, exposing milk products to these high temperatures also involves risking the appearance, taste, and nutritional value of milk. Proteins in milk are denatured at high temperatures, which results in the cheese-making property of milk being drastically impaired by the intense heat. UHT can also dramatically impact the quality and taste of the dairy product, which is another reason why selecting an ideal time/temperature combination is extremely important and a choice that must consider both the microbiological effects and product quality aspects.

The ability to control the milk product’s temperature throughout all processing stages is one of the most important aspects of assuring product quality in the dairy industry. Hot water and low-pressure steam are the two most commonly used heating mediums. A specific amount of heat is transferred from the heating medium to the milk product so that milk’s temperature increases and the heating medium’s temperature decreases correspondingly. These two substances must display a significant temperature difference to transfer heat effectively. The heat will flow from the warmer substance to the cooler substance, and the larger the temperature difference, the more rapid the heat flow. The rate of transfer begins to decrease as the two substances start to approach an equilibrium value. Heat can be transferred in three ways: conduction, convection, or radiation. Conduction and convection are the two most common methods used by a heat exchanger to regulate a substance’s temperature. In a plate heat exchanger, a partition is placed between the product (milk) and the heating or cooling medium (water). The partition is heated on the medium side and cooled on the product side. There is a boundary layer located on either side of the partition that heat is transferred to by conduction and convection. Once the liquids begin to approach the boundary layer, their velocity decreases to almost zero, so they can effectively transfer heat through the partition. This process continues until the heat transfer rate starts to decreases as the two substances approach an equilibrium temperature.

Most dairy producers use a process known as regenerative heating and cooling to regulate their milk products’ temperature. In many cases, a product must be heated for certain treatments and then cooled afterward. One example of this type of heat treatment is pasteurization. During pasteurization, chilled milk is heated from approximately 4°C to 72°C, held at this temperature for 15 seconds, and then cooled to 4°C again. The heat from the pasteurized milk is then repurposed and used to warm the incoming cold milk. The cold milk is heated by the high-temperature outgoing hot milk, which is simultaneously cooled. This process saves heating and refrigeration energy, which will also lead to the company saving more money. To prevent the growth of microorganisms, milk must be cooled to a temperature below 5°C before and after pasteurization. These processes occur in a heat exchanger and are referred to as either regenerative heat exchange or, more commonly, heat recovery. As much as 94-95% of the heat content of pasteurized milk can be recycled.

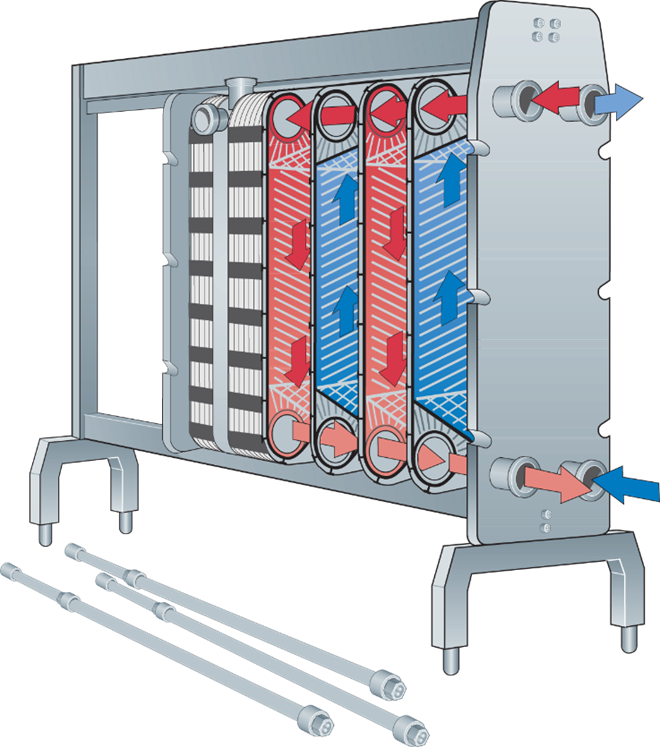

Plate heat exchangers are the most common and efficient method of heat transfer designed specifically for fluid products. On a basic level, a heat exchanger consists of multiple metal plates installed within a frame. Fluid passes through these plates allowing heat to transfer from the hot side to the cold side of the exchanger. These fluids must exhibit a specific velocity while passing across the plates to effectively transfer heat while also controlling the substance’s pressure. Well-designed heat exchangers must address three major challenges that most dairy companies face when it comes to milk processing. These challenges include maximizing run times, promoting cleanability, and keeping up with ever-changing food trends.

Figure 3: Heat exchanger that is generally used for dairy processing procedures. Source: https://dairyprocessinghandbook.tetrapak.com/chapter/heat-exchangers

Parameters like the fluids’ physical properties, their flow rate, the pressure drop, and the cleanability needs should be considered when designing and calculating the size of a heat exchangers.

Every time a fluid is cooled or heated, the flow occurred can be laminar or turbulent or conversion from one to the other flow, while the flow of the flow maybe is happening because of forced or natural convection. There are also different fluid flowing directions, like parallel, perpendicular or at an angle to the heating surface.

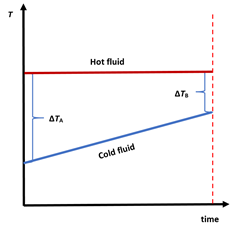

For the calculation of the heat transfer area of the heat exchanger, it is very important to know the logarithmic mean temperature difference (LMTD), which is the temperature difference of the hot and the cold fluids between the entrance and the exit of the heat exchanger. As a general rule, the engineers now that the higher the difference, the smaller the heat exchanger size because a higher amount of heat is transferred. Except for the case of thermal sensitive products, where there are limitations in the temperature difference.

Figure 4: An example of the temperature profile of heat transfer in a heat exchanger

For A heat exchanger, the heat transfer equation is:

Q = U · A · LMTD = V · ρ · Cp · ΔT

where

Q = heat flow rate

A = heat flow area

U = overall heat transfer coefficient (depending on the thermal conductivity of the heat transfer fluid and the product)

LMTD = logarithmic mean temperature difference [K] =

V = fluid flow rate

ρ = fluid density

Cp = specific heat of the fluid

ΔΤ = temperature difference between the inlet and the outlet

As shown in the equation, fluid properties like thermal conductivity, specific heat, viscosity, and density are important parameters for the heat transfer calculation.

The accurate knowledge of the fluids’ thermal properties is crucial for the design of a heat exchanger. Its efficiency can be improved, health risk accidents can be eliminated, fouling of the heat exchanger, and cleaning costs can reduce, resulting in a reduction of building and operation costs for the company and the final product.

Heat exchangers have become a critical component of dairy processing, and without them, many milk products would be deemed unsafe for consumption due to the growth of harmful microorganisms. Heat exchangers are used for multiple treatment processes, including pasteurization, sterilization, and other food processing needs. Most dairy producing companies use a plate heat exchanger to perform these tasks due to their versatility in design and size. Different dairy products require different treatment temperatures and times, so it is extremely important for a producer to ensure they are selecting the heat exchangers best suited for the task to effectively treat the milk product before it is consumed.

Author: Kallista Wilson | Junior Technical Writer | Thermtest

Garver, K. (2016, September 26). The Latest in Heat Exchangers for Food Processing.

Retrieved August 11, 2020, from https://www.myprocessexpo.com/blog/industry-perspectives/the-latest-in-heat-exchangers-for-food-processing/

Government of Canada, C. (2020, January 22). Government of Canada. Retrieved August 11, 2020, from https://www.inspection.gc.ca/preventive-controls/dairy-products/dairy-processors/heat-exchangers/eng/1579546813867/1579546894609

Heat exchangers. (2020, June 29). Retrieved August 11, 2020, from https://dairyprocessinghandbook.tetrapak.com/chapter/heat-exchangers

Proper cleaning and sanitizing of heat exchangers keeps food safe. (2015, October 12). Retrieved August 11, 2020, from https://www.dairyfoods.com/articles/91414-proper-cleaning-and-sanitizing-of-heat-exchangers-keeps-food-safe

McCabe, W. L., Smith, J. C., & Harriott, P. (1993). Unit operations of chemical engineering (5th ed.). New York; London: McGraw-Hill.