Join us at the International Thermal Conductivity Conference (ITCC) and the International Thermal Expansion Symposium (ITES).

February 16, 2024

May 4, 2021

September 26, 2019

May 25, 2021

October 30, 2019

April 18, 2022

The devastating effects climate change is inflicting on the health of our planet has been making headlines for decades. Despite this environmental damage being extremely well publicized, the push for society to mitigate these impacts has only recently become evident in the way countries and their associated industries operate. The overexploitation of fossil fuels coupled with the rapid development of pollution plagued factories has been linked to the majority of the problems our natural world is currently facing. Methods and alternatives to replace these unsustainable processes are starting to come into effect across a number of different industries, all sharing a common goal of reducing both the energy demands and emissions associated with them.

The poor design and selection of materials used during the construction of homes and buildings stick out like a sore thumb in terms of the harmful impacts these can impose on the state of the environment. Most residential homes are developed with little environmental consideration and because of this, they are a huge source of greenhouse gas emissions. Most of the pollution associated with a home comes from the energy that is used for heating or cooling its interior. This energy is normally derived from fossil fuels which have been well publicized as being one of the largest contributors to global climate change.

The Pan-Canadian Framework on Clean Growth and Climate Change has already highlighted the energy demand associated with home and building thermal regulation as a major source of environmentally damaging emissions. Recent studies have estimated that approximately 12% of Canada’s greenhouse gas emissions are linked to this steep power requirement with an even higher 17% emission rate if the amount of energy lost from a home or buildings due to their poor design is accounted for. One of the most effective methods to reduce both emissions and costs associated with interior temperature regulation is to increase the effectiveness and thermal resistance of a building’s insulation.

A material’s thermal resistance reflects its ability to restrict the flow of heat through it. Thermal resistance can also be considered as the reciprocal of thermal conductivity, a common measurement for describing the heat distributing potential of a given object or material. The insulation that is used to create a building envelope should have a naturally low thermal conductivity and therefore, a high thermal resistance. The higher this resistance value, the greater the ability of the insulation material to prevent the flow of heat through it, therefore, lowering the energy requirements of an entire home or building.

A couple of steps that can be taken to boost the effectiveness of a building’s insulation include swapping the insulation material for one that has a higher thermal resistance, or increasing the thickness of the walls. The latter of the two is a less than ideal solution as an increase in wall thickness can pose many challenges to building designers, especially when space is limited. One insulation material that has been gaining popularity for its extremely low thermal conductivity and ability to reduce both the energy and cost required to heat a building is vacuum insulation.

Figure 1: An example of conventional filled insulation that demands a large amount of space compared to vacuum insulation

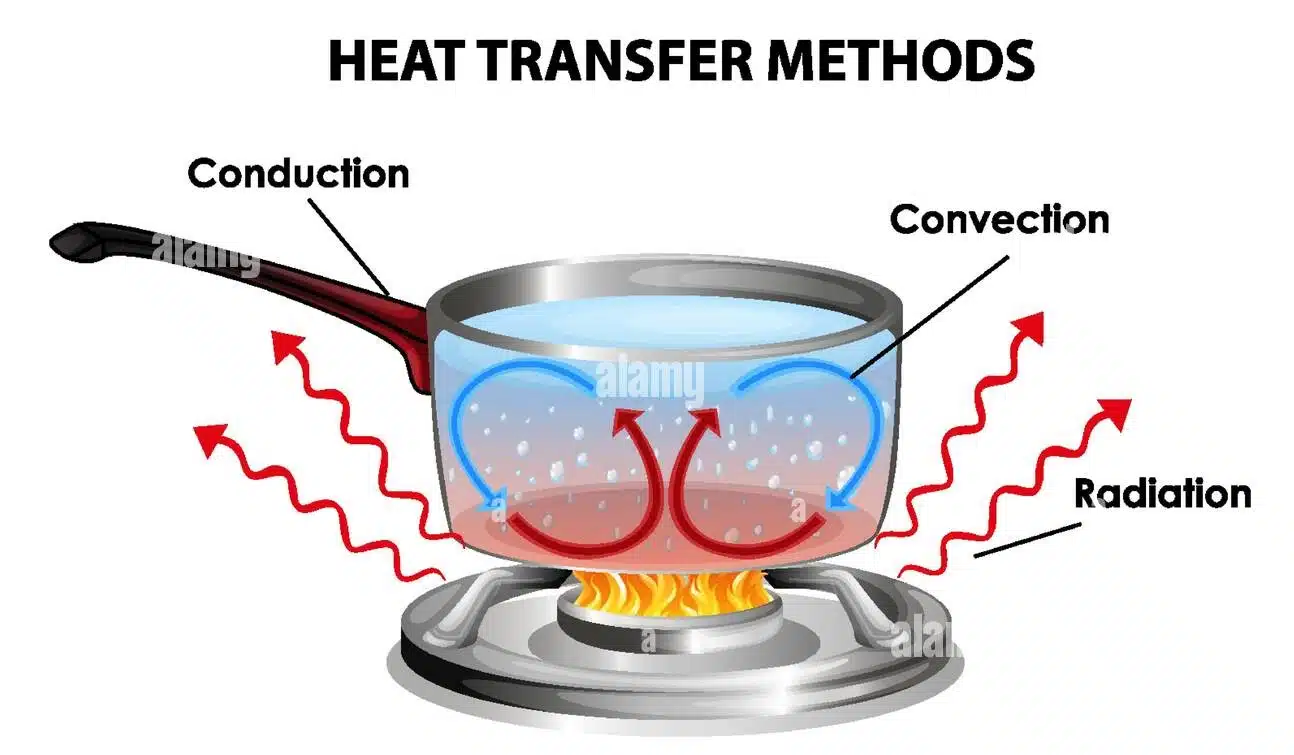

This state-of-the-art insulation material takes advantage of the lack of conduction present within a vacuum to deliver high quality protection against heat loss. Most heat loss that occurs between the walls of a building and its exterior environment is through conduction. Conduction happens through the collision of molecules without any movement of the physical material or objects. A vacuum is almost completely deprived of all molecules so it naturally prevents all heat transfer by conduction. Convection is another mechanism of heat movement that is absent from any type of vacuum. For convection to occur, there needs to be a gas presence to act as a current that transports heat. Since a vacuum lacks all gas, heat transfer by convection can’t occur.

Figure 2: Mechanisms of heat transfer that occur in a pot over a stove.

One mechanism of heat transfer that even a vacuum is susceptible to experiencing is radiation. Any object or material with a temperature above absolute zero emits energy in the form of radiation. Although the amount of energy released is heavily dependent on its ambient temperature, it is impossible to completely prevent all radiating heat loss from occurring. Luckily, this can be minimized by coating the inside of a vacuum chamber with a highly reflective coating such as a thin layer of aluminum or stainless steel to prevent radiate heat loss as much as possible.

Figure 3: Example of a thin, metalized vacuum insulation panel.

Most conventional insulations rely on the poor thermal conductivity of air to boost their heat blocking potential. For example, plastic foam contains thousands of tiny air bubbles to restrict the movement of heat through it. Vacuum insulation is the complete opposite, and instead contains a region that has been completely evacuated of all air. The insulation panels are constructed with highly porous inner layer and a very thin outer layer or ‘envelope’. During the installation process, air is completely evacuated from this envelope which seals the vacuum chamber located internally. The core material of a vacuum must be made strong enough to resist the mechanical pressure imposed on it from the creation of this tight internal environment. The vacuum’s outer envelope is generally made of a material that is impermeable to various forms of gas and water vapor. If either of these penetrate the envelope, it will significantly reduce both the lifespan and the insulating ability of the vacuum insulation panel.

Some manufacturers claim that they can produce vacuum insulation with a thermal resistance value less than R -40/inch, however, these estimates neglect to consider the impact a highly conductive perimeter has on the quality of the insulation. On average, there is roughly a 32% drop in thermal resistance along the perimeter of a panel due to the presence of a thermal bridge that provides the seal to the metallized vacuum interior. Manufacturers may use several different techniques to create the vacuum seal and as a result, the impacts this folding technique has on the overall thermal performance of the panel can vary. On average, a vacuum insulation panel will have a thermal conductivity value of 2-4 W/(m/K) and may reach as high as 8 W/(m/K) after 25 years or more of wear and tear.

Thermal conductivity values this low are almost unheard of in the insulation world and deliver an exceptionally high standard of protection against heat loss. Vacuum insulation panels are also significantly thinner than convention insulations such as polystyrene or polyurethane. This means that they not only save the home owner energy and money by efficently heating and cooling the interior, but they also save them a significant amount of space.

Despite there being plenty of benefits associated with installing vacuum insulation in a home there are still some pitfalls that must be taken into consideration. If an insulation panel gets punctured or damaged, its ability to provide a stable thermal barrier can quickly become compromised due to there being a greater chance it will experience heat transfer through both conduction and convection. Throughout the home building process, there are plenty of hazards such as nails or screws that can puncture an insulation panel. Depending on the degree of damage, a puncture to a panel can cause conductivity values to spike as high as 20 W/(m/K) which is the standard thermal conductivity value of a poorly manufactured and installed foam insulation. Because the effectiveness of this type of insulation relies so heavily on the performance of the vacuum, it is crucial that the panels be installed carefully and without exposure to any additional hazards that are common to a construction site.

Figure 4: Common items found at a construction site that have the potential to inflict damage on a vacuum insulation panel

Installing vacuum insulation panels is a great example of an initiative a homeowner can take to reduce their carbon footprint by lowering the energy demands associated with heating and cooling their home. Not only will the installation of this thermally resistive material lower energy costs, but it will also contribute to the global effort to minimize the impacts of climate change. Switching all insulation materials to vacuum insulation, or another low thermally conductive alternative, would have a profound impact on the amount of greenhouse gas emissions our atmosphere experiences annually. If these small modifications to society’s daily way of life occurred on a larger scale, it would be the push our planet needs to surpass sustainability goals and start righting many of the wrongs the industrial processes of the past have inflicted on the state of our environment.

Author: Kallista Wilson | Junior Research Assistant | Thermtest

Conley, B., Cruickshank, C. A., & Baldwin, C. (2018). 2.24 Insulation Materials. In I. Dincer (Ed.), Comprehensive Energy Systems (pp. 760–795). Elsevier. https://doi.org/10.1016/B978-0-12-809597-3.00252-2

How Does Vacuum Insulation Work? (n.d.). Retrieved February 25, 2022, from https://homeguides.sfgate.com/how-does-vacuum-insulation-work-13408054.html

Moore, T. (2018). Evaluating the Thermal Resistance of a Vacuum Insulation Panel Wall Assembly Containing Thermal Bridges using Industry Standard Calculation Methods and Numerical Simulation Techniques [Master of Applied Science, Carleton University]. https://doi.org/10.22215/etd/2018-12690

Petter Jelle, B. (2016). 8—Nano-based thermal insulation for energy-efficient buildings. In F. Pacheco-Torgal, E. Rasmussen, C.-G. Granqvist, V. Ivanov, A. Kaklauskas, & S. Makonin (Eds.), Start-Up Creation (pp. 129–181). Woodhead Publishing. https://doi.org/10.1016/B978-0-08-100546-0.00008-X

Vacuum Insulation Panels—Thermal Insulation. (n.d.). Nuclear Power. Retrieved March 3, 2022, from https://www.nuclear-power.com/nuclear-engineering/heat-transfer/heat-losses/insulation-materials/vacuum-insulation-panels/